BenCC

Supporting Vendor

Greetings. This is a half build and half promoting thread. I want to document my 3d printed parts/accessories and share the design/fabrication process.

List that shows what is currently available to purchase:

Suggested Project List:

List that shows what is currently available to purchase:

Make 1: Scangauge II Mount for Toyota Land Cruiser 100 Series

Make 2:

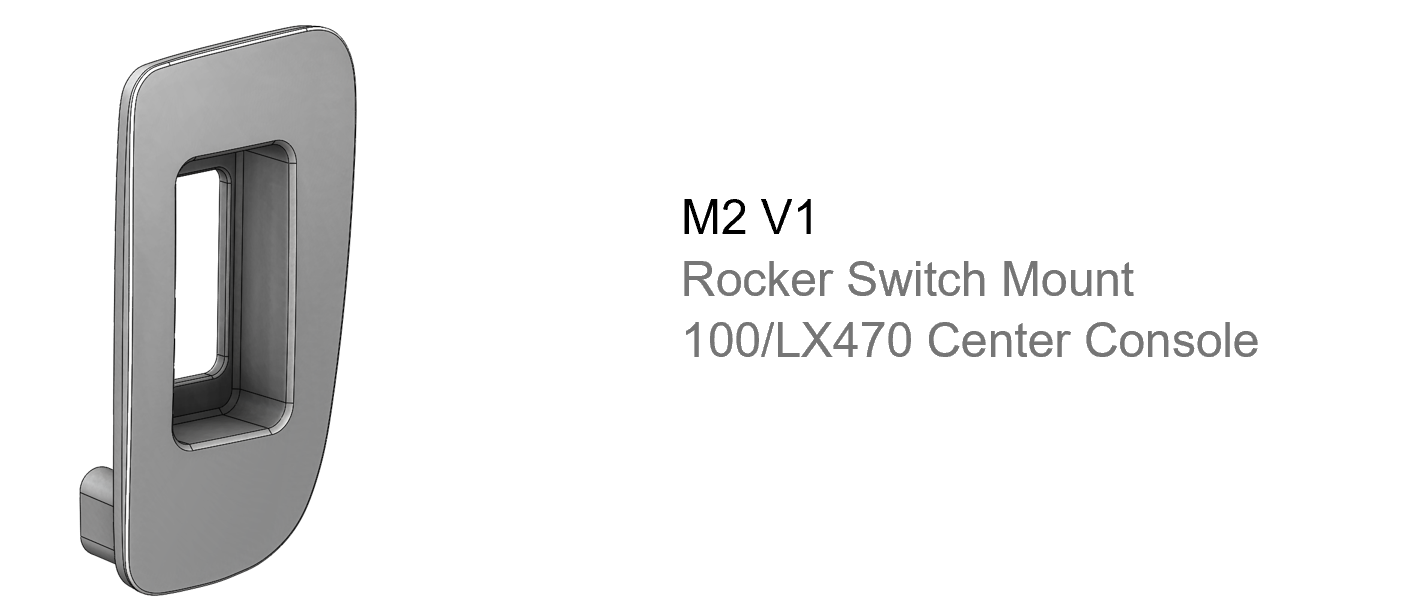

M2 V1: Rocker Switch Mount for the Lower Right Center Console Panel

M2 V2: RAM Ball Mount for the Lower Right Center Console Panel

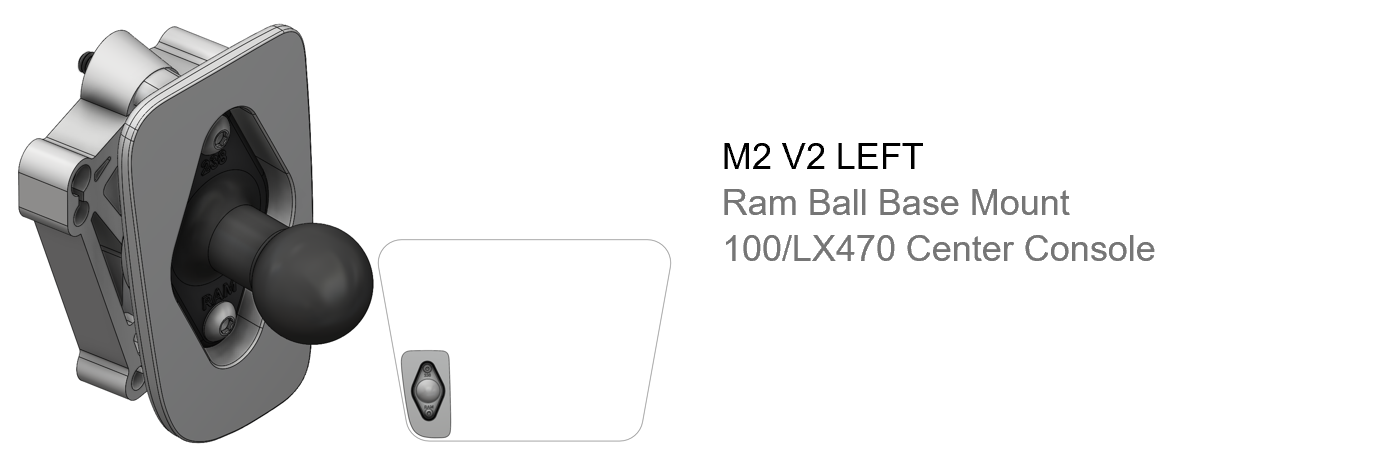

M2 V2 LEFT: RAM Ball Mount for the Lower Left Center Console Panel

M2 V3: Magnetic Mic Mount

Make 3: Scangauge II Mount for Toyota Tacoma Gen 2

M3 V1 Scangauge II Mount for Toyota Tacoma Gen 2 Type 1

M3 V2 Scangauge II Mount for Toyota Tacoma Gen 2 Type 2

M3 V3 Rocker-switch Mount for Toyota Tacoma Gen 2 Type 1

M3 V4 Rocker-switch Mount for Toyota Tacoma Gen 2 Type 2

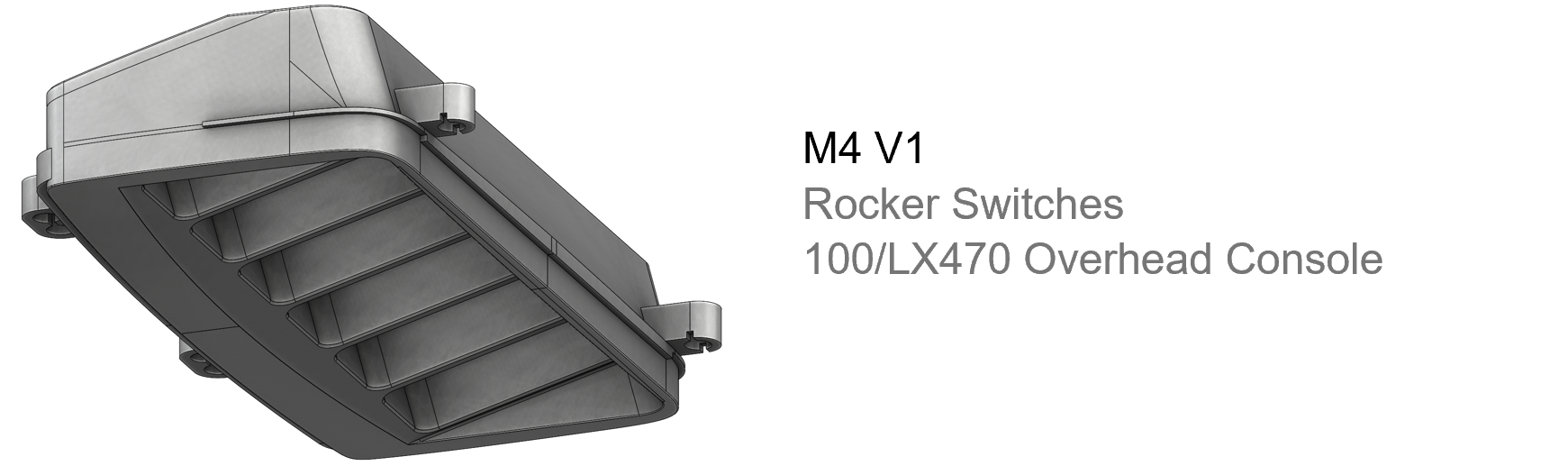

Make 4: Multiple Rock Switches Mount for Toyota Land Cruiser 100 Series

M4 V1: Six Rocker Switches

M4 V2: Five Rocker Switches + One Map Light

M4 V3: Extra Clearance (ARB Style Automotive Rocker Switches)

M4 V3T: Extra Clearance (Toyota OEM Switches)

M4 V4: Extra Clearance with one Slot for Dimmer

Make 5: Scangauge II and Rock Switches Combo Mount for Toyota Land Cruiser 100 Series

Make 6: Change Pocket Mount

M6 V1-V5: Change Pocket Mount

M6 V6: Change Pocket RAM Ball Base Mount

Make 7: Rear Cooler Switch Hole Mounting Plate

Make 8: Voltmeter Mount

Make 9: Kenwood TM-V71A Remote Head Mount

Make 10: Multi-switch Mount with 12V Outlet or USB Ports

Make 11: Scangauge II Mount with 12V Outlet or USB Ports

Make 12: Scangauge II Mount for Mini-Homelink Overhead Console

Overview of three versions

M12 V1: Round-up

M12 V2: Square-off

M12 V3: Minimalist

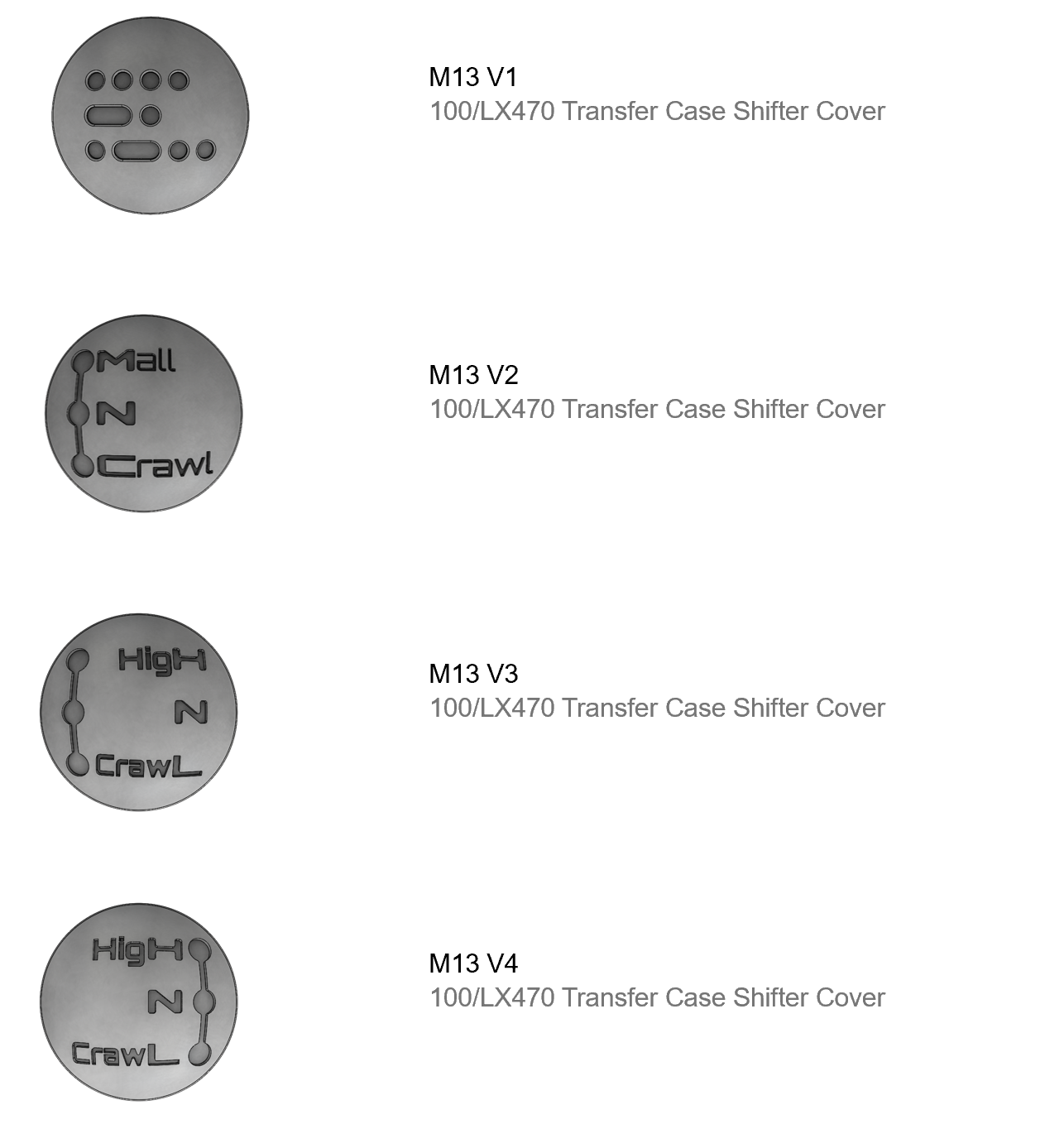

Make 13: Transfer Case Lever Cap

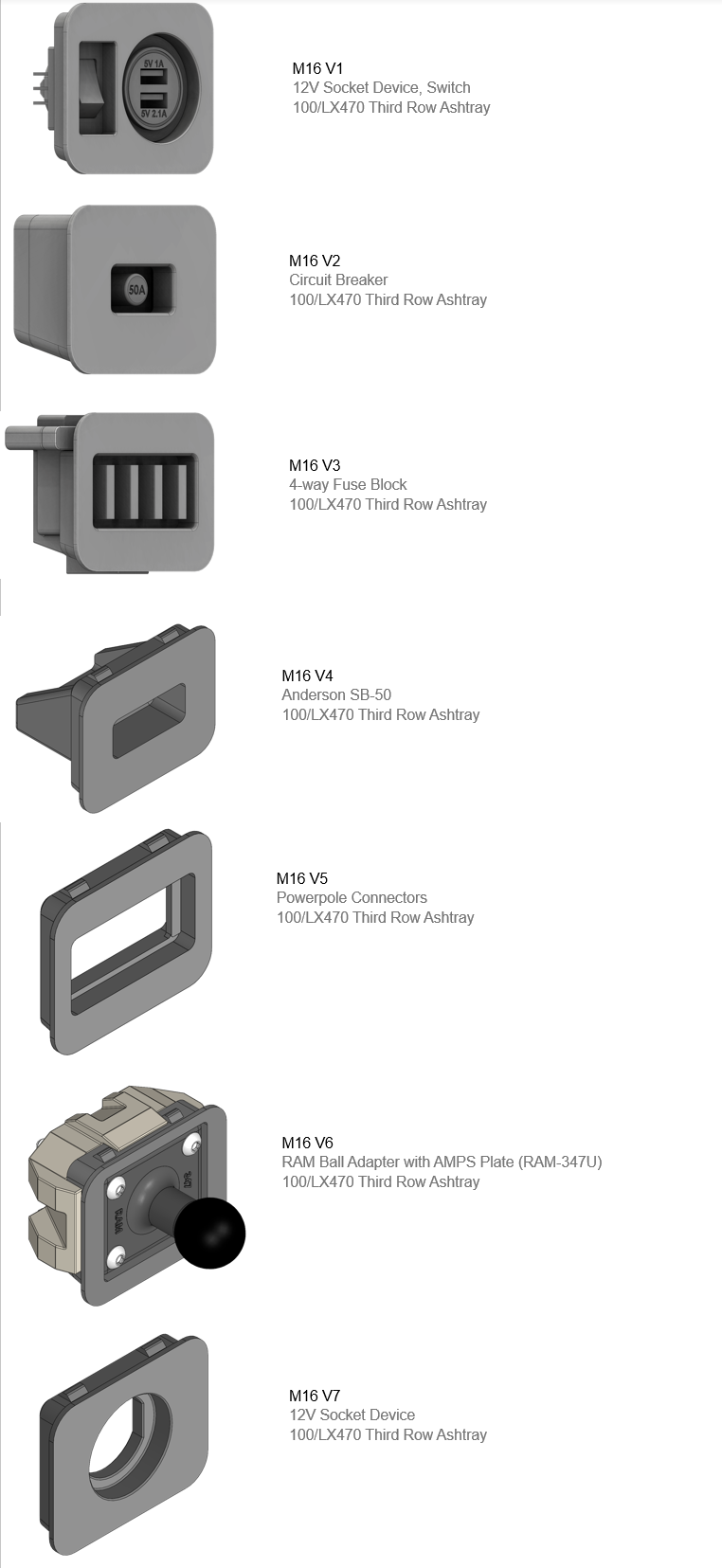

Make 16: Third Row Ashtray Replacement Panel

Make 17: Sub-woofer Cover

Make 18: Third Row Cup Holder Replacement Panel

Make 19: Fot Light Mount for 100 Series Only

Make 19 V1: Fog Light Mount (Rigid D2)

Make 19 V2: Fog Light Mount (Baja Designs Squadron)

Make 19 V3: Fog Light Mount (Diode Dynamics SS3)

Make 19 V5: Baja Designs Squadron and S2 Mount

Make 21: Overhead LED Replacement

Make 22: Kenwood TM-D710G Remote Head Mount

Make 23: YAESU FTM-400XD Mount

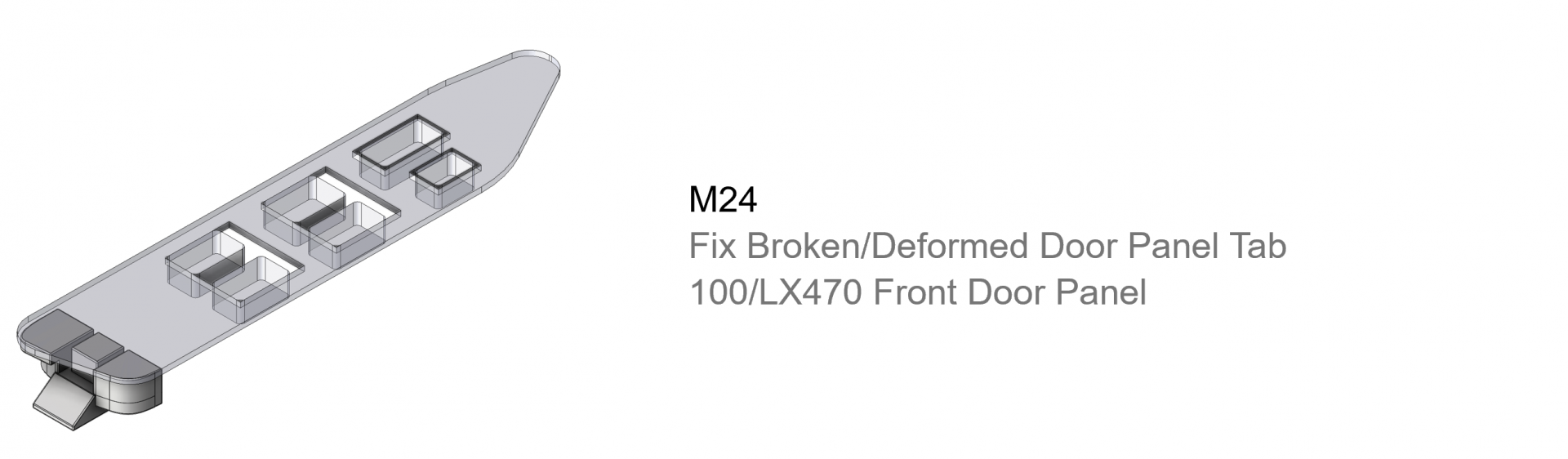

Make 24: EZFix of door switch panel

Make 25: Door Step (Door Trim Protector)

Make 26: Wheel cap for Method NV Wheel

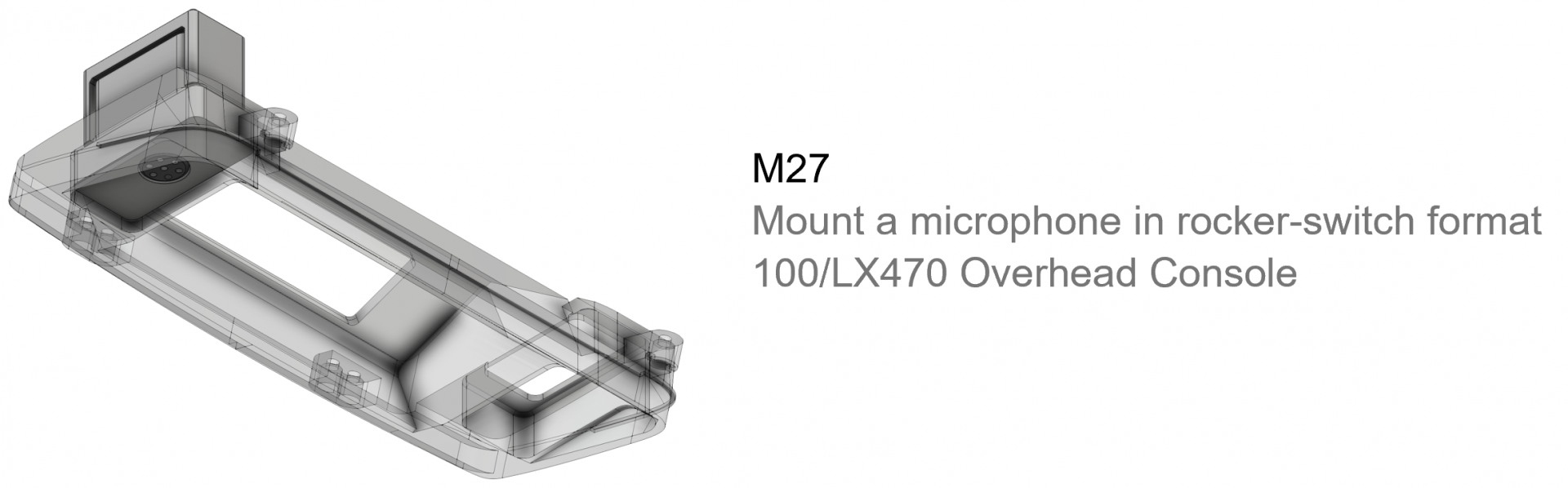

Make 27: Mic Adapter in Rocker-switch Format

Make 28 V1: Cupholder (Butterfly version) Instruction

Make 28 V2: Cupholder (Non-Butterfly version)

Make 29: Second-row Cupholders Replacement

Make 30: Keystone Device Mount in Rocker-switch Format

Make 33: Center Storage Insert

Make 34: Hazard/DiffLock Switches Swap Kit

Make 35: Switch Pros SP-9100 Switch Panel Mount

M35V1: For regular overhead console

M35V2: For minilink overhead console

Make 36: ICOM IC-2730 Mount

Make 37: Icon Compression/Rebounds Wheel Caps

Make 40: Small Rocker Switch Mount for Mini-Homelink Overhead Console

Make 41: RAM Mount Compatible Multi-function Fixture

Make 42: Dummy Flange

Make 46: Center Storage Deep Hole Utilization

Make 50: Hood Struts Safety Clip

Make 53: TJM T17 Baja Designs S2 Mounting Kit

Make 59: AUXBEAM Switch Panel Mount

Make 60: sPOD Switch Panel Mount

Make 63: LX470 Foglight Mount

Suggested Project List:

- Ashtray mount for rocker switches or USB ports.

- Third row AC redirection duct.

- A panel to replace the original panel by the left knee.

- Rocker switch mount at the center console pocket (See Make 6).

- USB charging port at the back of the center console (See Make 7).

- Cup holder

- Kenwood TM-V71A remote head mount (See Make 9).

- Multi-switch mount with 12V outlet (See Make 10).

- Scangauge II mount with 12V outlet (See Make 11).

- Something in Door Ashtray Slots (by savirc).

- Scangauge II mount for the mini HomeLink console (See Make 12).

- Third-row Ashtray Panel (See M16 V1).

- Third-row Cup Holder Panel (See Make 18).

- Subwoofer Panel

- Shifter Knob

- Morimoto XB universal kit mount ( from @spaber05)

- 7in round headlight replacement (from @jay3253)

- Variation of M2 to mount a Ram ball (from @geanes and @gregnash) (See M2 V2)

- "...my overhead DVD played didn’t work when I bought the truck. I have no idea what could go there, but it would be pretty cool to see what you come up with! Maybe a pocket for CB radio with some lights on the sides? Or maybe just a piece that holds some LEDs that can be wired into the cargo lights so they come on when the doors open? " (from @aaronrules)

- something to fill part of the door slot @Otter

- A snap on cover that prevents items from blocking or restricting air intake for those with rear A/C @James Bentley

- "Ben, I was thinking about the ash tray in front. I know if I pull the tray out my iPhone 11 (pro) will fit. I was wondering if you could fab up a shelf that could have a built in Qi charger. A person could then enter, slide the phone in and it would charge (and if you had wireless CarPlay or whatever the android version is) you’d be coed free and the phone would be out of the way.“ @CBdeJ

Last edited: