With the battery terminations brought up to standard it was time to get some power to the back of the truck... for at least my fridge/freeze and on-board compressor. This setup mimics what I'd done in my 80-series in the UAE. Very helpful and practical upgrades.

Started with a 100-amp circuit-breaker protected run of 4AWG cable running through the truck...

Runs from the battery to driver's side of the truck and then into the cabin via the harness gasket.

Runs under the front mat along the doorsill, up into the back of the cabin and into the rear panel area, and terminates at the intended location of the accessories. Running with the power cables is an extension of the relay control for the compressor.

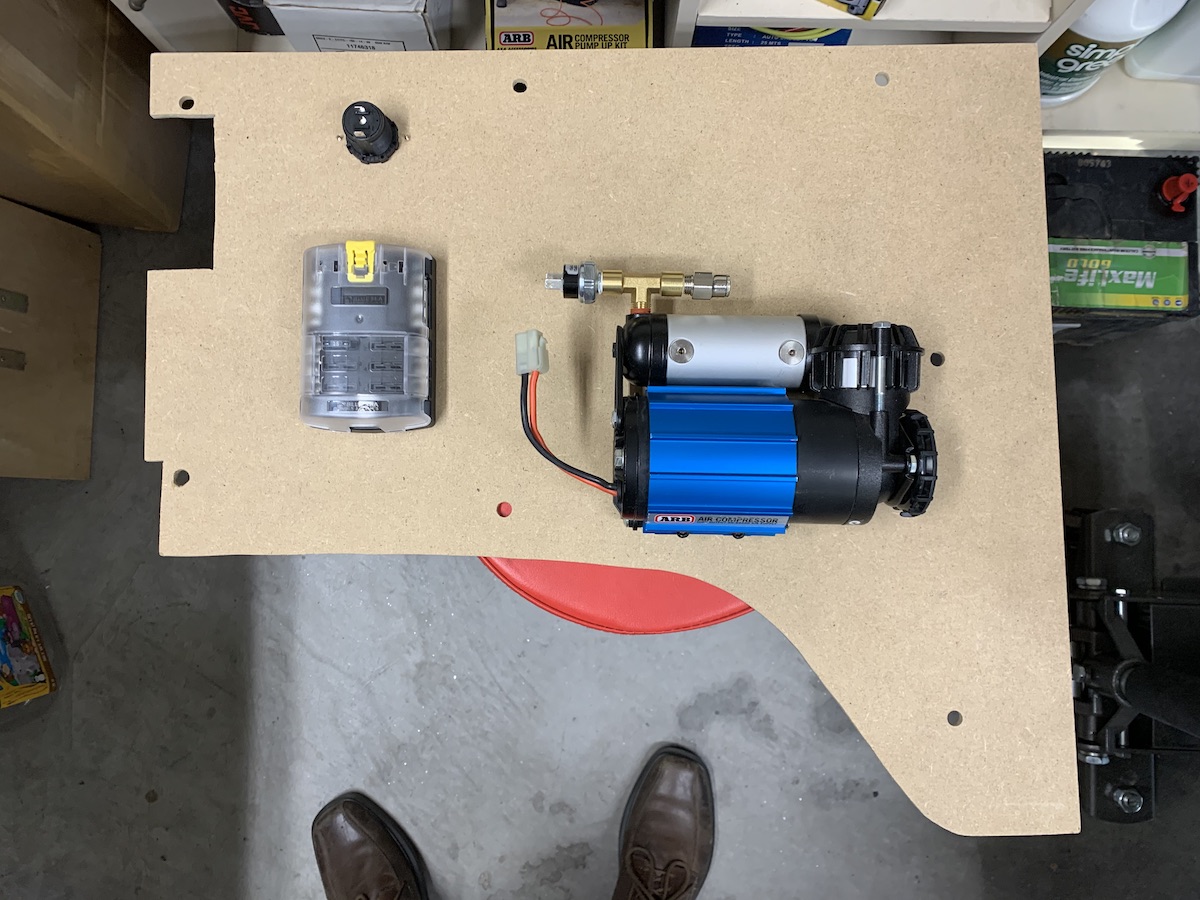

Here are the accessories mounted on some MDF cut to make a panel. This is a temporary setup to see how well I could get things mounted and cut to fit. I'm going to do some nice plywood for all panels at some point. A Bluesea fuse block, Bluesea 12V socket, and an ARB compressor. The fuse block will eventually power a few more sockets, USB outlets, and interior lighting.

Four mounting the panel I was tempted to use rivnuts in the existing holes intended for the snap-in plastic pieces. But instead I used cage nuts (an idea from the Troopcarriers of Australia CAD file). These are M6 cage nuts from McMaster Carr, similar to those used in service racks. Take the round holes and file them square...

And cage nut pops right in and gives you a semi-floating nut to screw into... which gives you some looser tolerances in the alignment of your panel mounting holes.

And then I used some flathead screws and countersunk washers for securing the panel.

I'm a bit bummed by the mounting hardware for the compressor and fuse block giving the panel a busy appearance, but I'm unsure how to mount without that happening. And this is a function-over-form setup for now.

I cleaned up my ARB quick-disconnect and painted up the mounting bracket (same one I used on my 80). Bought some

@NLXTACY kit... a pacifier for the disconnect, as well as 3/8" tube and push fittings. If you have an 80-series there's lot of good stuff available from him.

The compressor fits into the panel cavity area really well.

And the disconnect is mounted to the inside of the rear crossmember and plumbed through the same gasket as the rear harness.

Switch has been wired in to the left of the steering wheel in one of the blanks. It illuminates with the other instruments and gauges and is only hot when the ignition is hot.

And now I've got full time power for my fridge freeze and on-board air. Handy.