- Thread starter

- #101

So, I had trouble reverse bleeding rear brake. problem was at the master cylinder, and I eventually bought a new one, but with all the checking/reading I found the real issue is the Brake Proportioning Valve.

This sits under the master Cylinder in an FJ62, and changes the orientation of the hardlines (so you cant just remove it, without changing hardlines). I also could not find any reference in any of my FSM's. Its meant to push braking to the front, if the rear looses presure. Its meant to be more for disc front, drum rear. Note. Some 60's also had a 'brake load' proportiing valve, which has a lever to the suspension and changes brake pressure based on load. After some research if you loose presure in the rears, then it ''fires' to fix it. However it then needs resetting. And I could find no instructions on how to do this. Some mentions about doing fronts first and pumping pedal, but nothing clear. A reset can be done on newer models, but they have an extra hole.

I could not find these brand new, and was looking for old ones. I could find a 'kit' to rebuild it, but it seems to be more for the 'brake load' version.

Anyway, finally I decided to have a look at it. The issue was that i could blow through one pipe, but not the other one. This matched the issue of the rears locked, and why I could not reverse bleed.

So I pulled it apart!

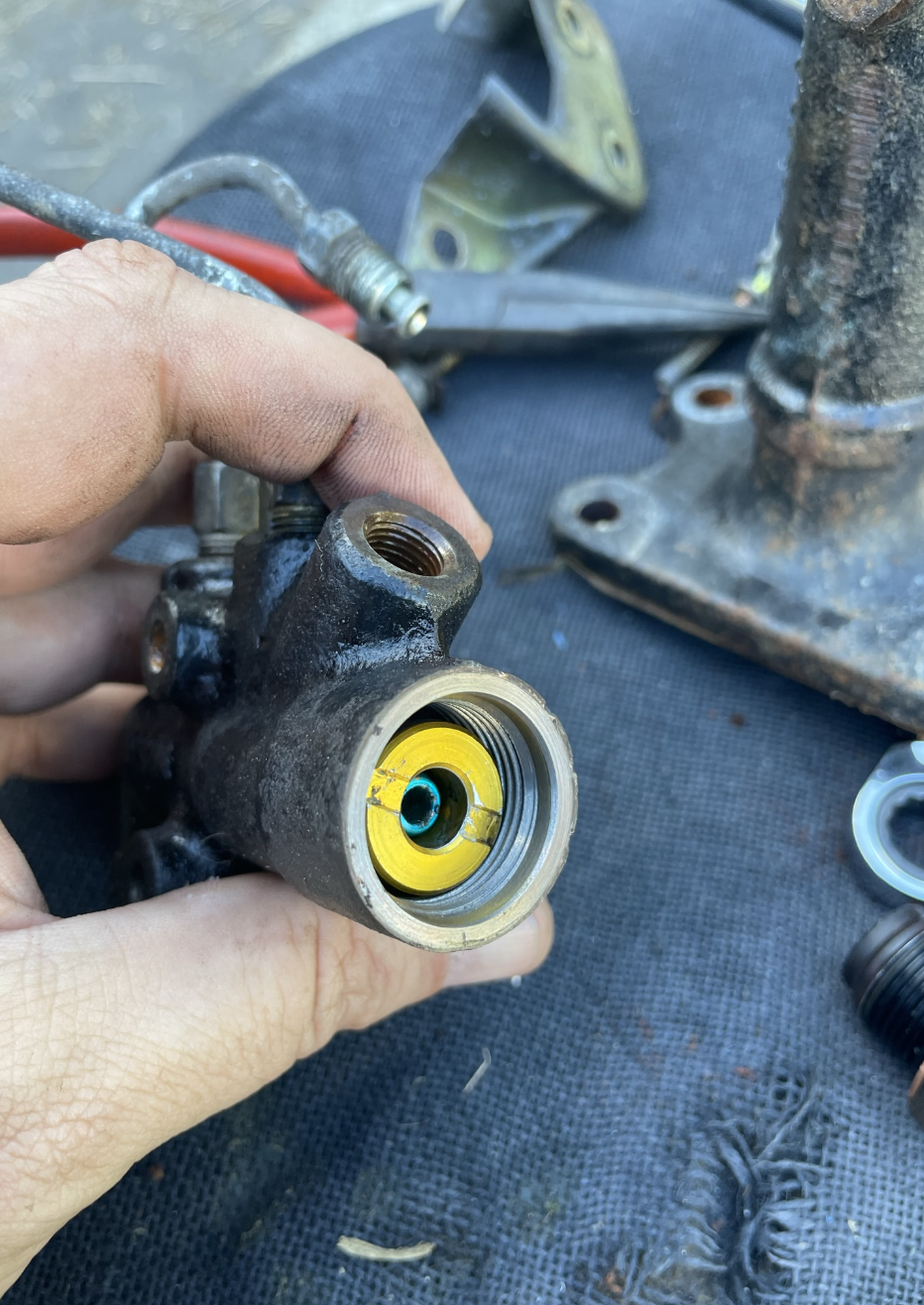

I unscrewed the big bolt at the end. Then I could see this gold and blue bit covered in gunk. The blue pin was sticking out of the gold bit, and I grabbed it with pliers and could pull it against a spring. Eventually the whole bit came out. This let me clean it all up with a rag. It had a rubber ring on the blue end which easily came off for me to clean. I then put it together and realises that the blue pin is NOT meant to stick out. This is what it should be;

The blue bit was STUCK all the way to the end which was the problem. Now with it out, and all put back together I could blow through both pipes.

I'll let you know how it works when I reconnect it and fill it back up again.

This sits under the master Cylinder in an FJ62, and changes the orientation of the hardlines (so you cant just remove it, without changing hardlines). I also could not find any reference in any of my FSM's. Its meant to push braking to the front, if the rear looses presure. Its meant to be more for disc front, drum rear. Note. Some 60's also had a 'brake load' proportiing valve, which has a lever to the suspension and changes brake pressure based on load. After some research if you loose presure in the rears, then it ''fires' to fix it. However it then needs resetting. And I could find no instructions on how to do this. Some mentions about doing fronts first and pumping pedal, but nothing clear. A reset can be done on newer models, but they have an extra hole.

I could not find these brand new, and was looking for old ones. I could find a 'kit' to rebuild it, but it seems to be more for the 'brake load' version.

Anyway, finally I decided to have a look at it. The issue was that i could blow through one pipe, but not the other one. This matched the issue of the rears locked, and why I could not reverse bleed.

So I pulled it apart!

I unscrewed the big bolt at the end. Then I could see this gold and blue bit covered in gunk. The blue pin was sticking out of the gold bit, and I grabbed it with pliers and could pull it against a spring. Eventually the whole bit came out. This let me clean it all up with a rag. It had a rubber ring on the blue end which easily came off for me to clean. I then put it together and realises that the blue pin is NOT meant to stick out. This is what it should be;

The blue bit was STUCK all the way to the end which was the problem. Now with it out, and all put back together I could blow through both pipes.

I'll let you know how it works when I reconnect it and fill it back up again.