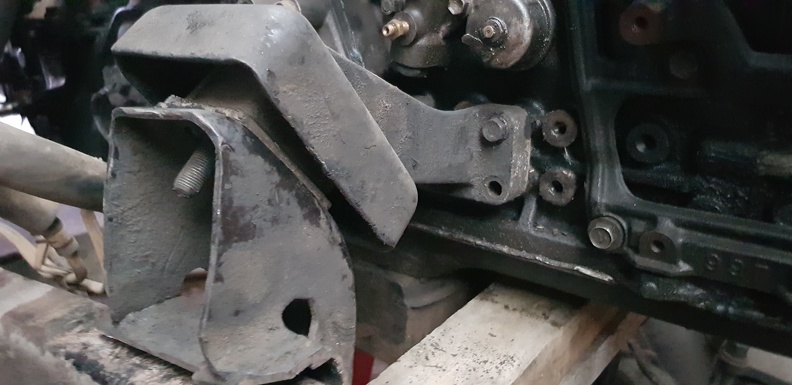

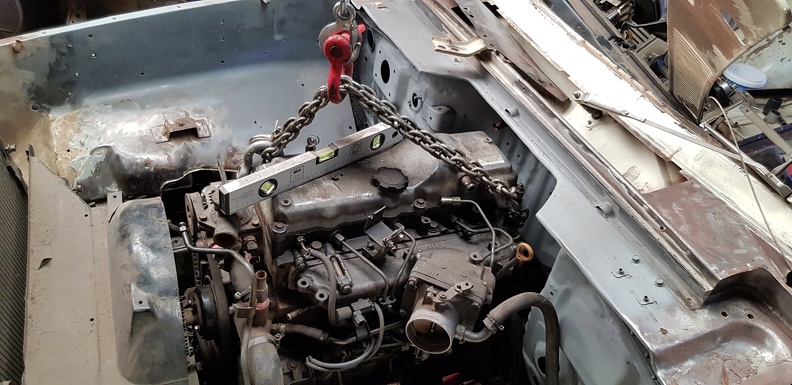

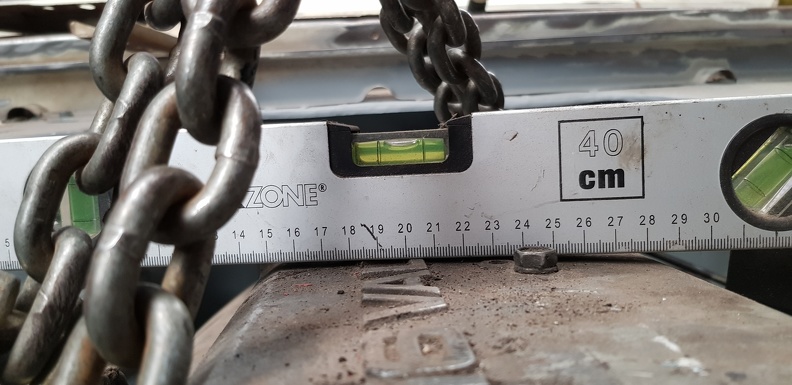

Nice. I actually tried 70 series mounts first. The engine was going to be too high without a lot of modification to those mounts so I switched to the 60 series.

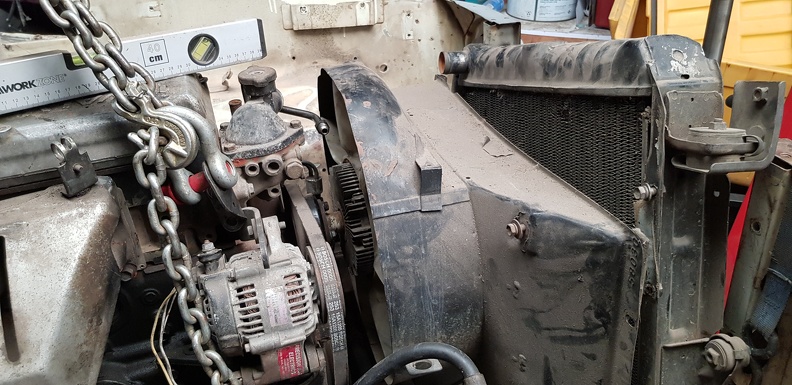

70 series front frame section is only 1/2" wider than the 55 but the 70 frame is somewhat flat front to back where the 55 has a higher arch over the axle.

Glad you got it to work. I had one of those engines a few years ago. Wish I could have kept it for this.

70 series front frame section is only 1/2" wider than the 55 but the 70 frame is somewhat flat front to back where the 55 has a higher arch over the axle.

Glad you got it to work. I had one of those engines a few years ago. Wish I could have kept it for this.