- Thread starter

- #141

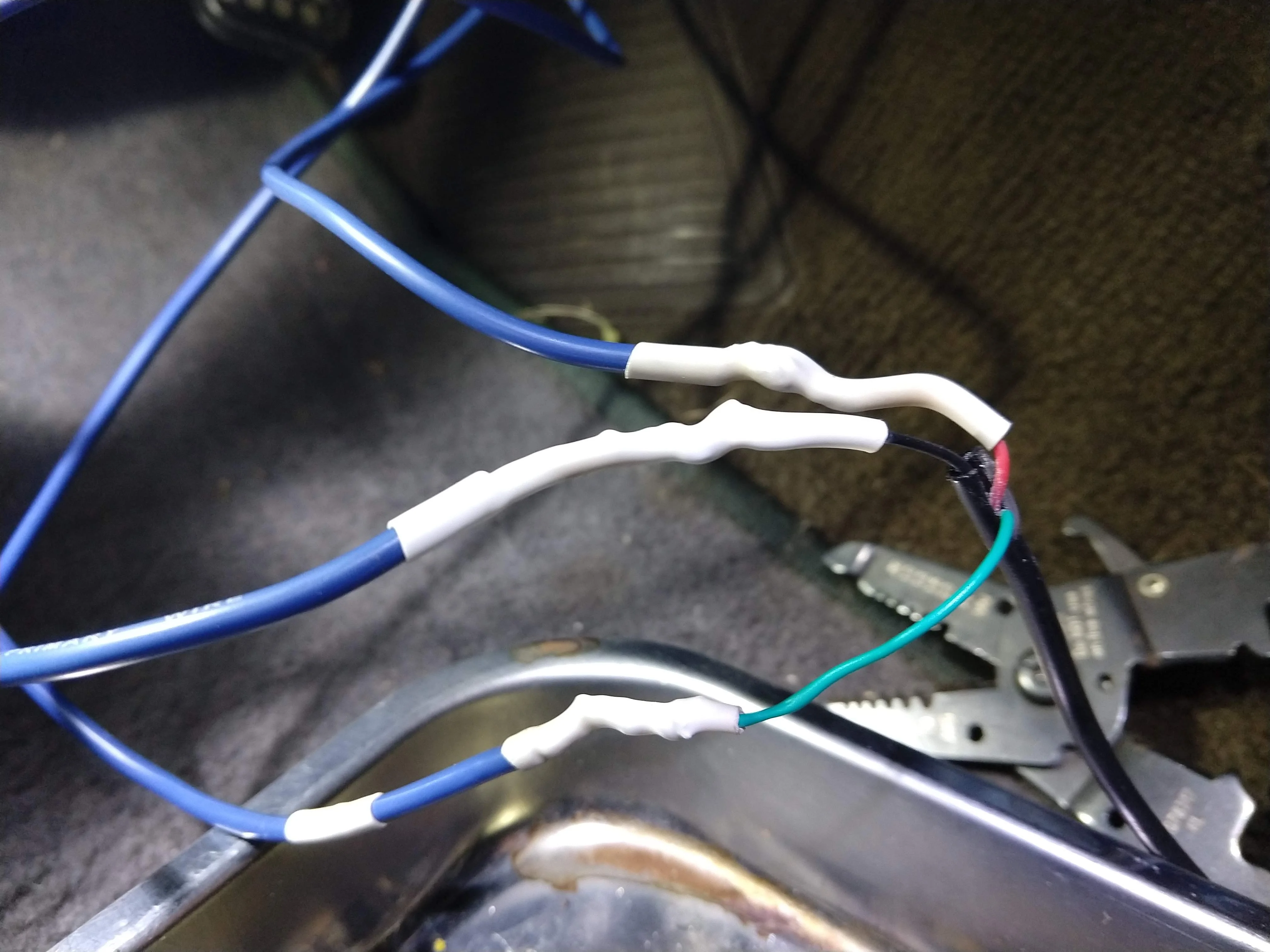

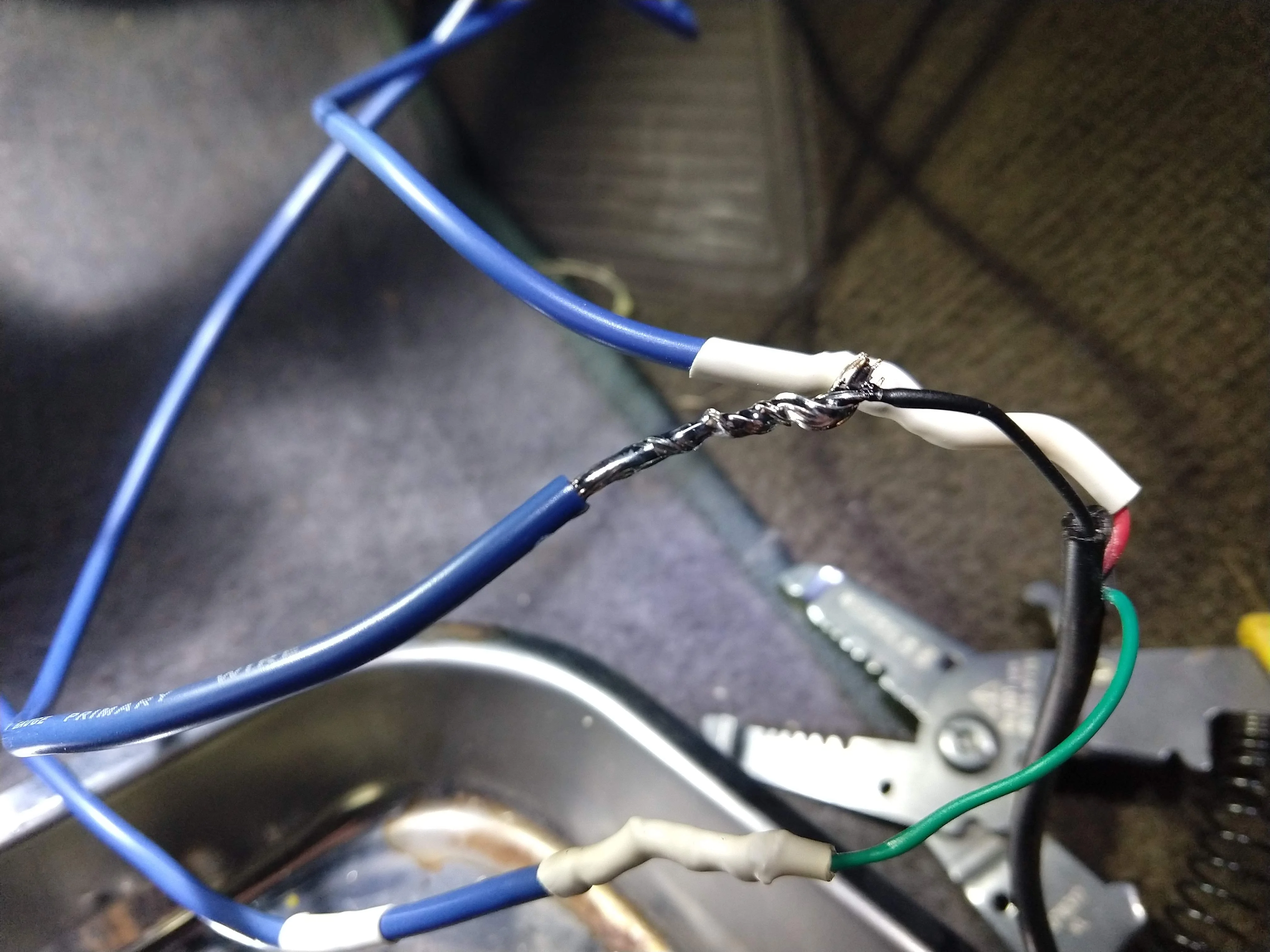

Finished the installation of the temperature gauge and cleaned everything up. Decided to solder the wires (duh - I should have always done this) and heat shrinked. Added some zip ties to make it look purdy under the dash. And mounted the gauge under the main dashboard bezel.

I think it looks pretty sweet.

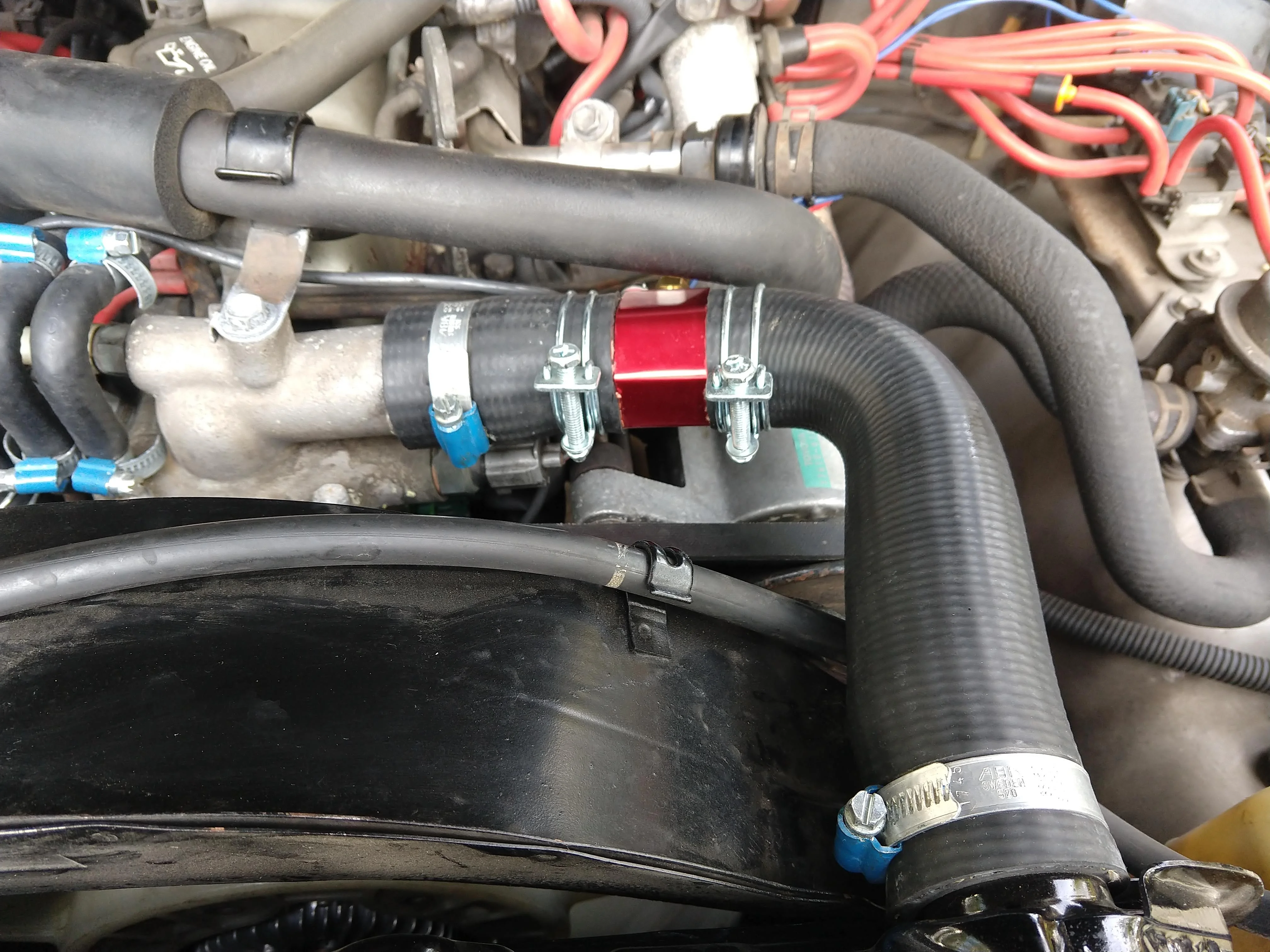

I've had a few small leaks with where I added the in-line adapter to the thermostat to upper radiator hose. But I am getting those kinks fixed by adjusting the tightness of the hose clamps and their placement on the hose. There might be a slight leak coming out of where I mounted the temperature sensor. I added teflon during the install, but it might require a little more teflon.

I think it looks pretty sweet.

I've had a few small leaks with where I added the in-line adapter to the thermostat to upper radiator hose. But I am getting those kinks fixed by adjusting the tightness of the hose clamps and their placement on the hose. There might be a slight leak coming out of where I mounted the temperature sensor. I added teflon during the install, but it might require a little more teflon.

Wiring after Solder

You can see the mercurial, glassy aspect of the solder on top of the wires after I have soldered...