- Thread starter

- #421

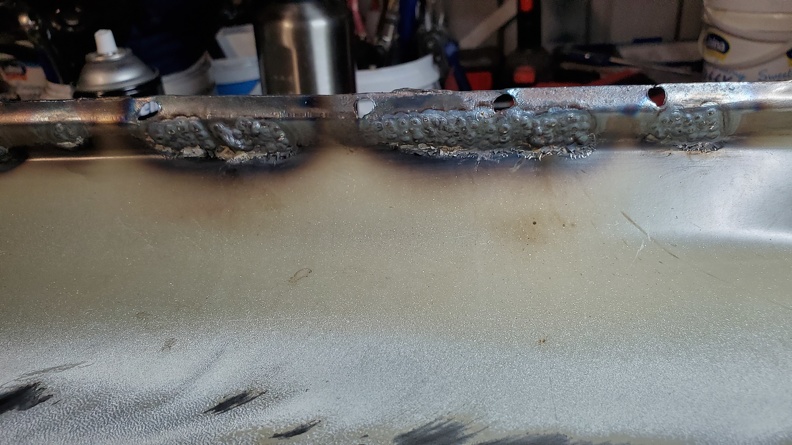

Last nights effort forming the lower a pillar

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Go man go!

forum.ih8mud.com

forum.ih8mud.com

looks like what i did View attachment 2207281

Also gotta figure out how to profile the back of the roof too