- Thread starter

- #261

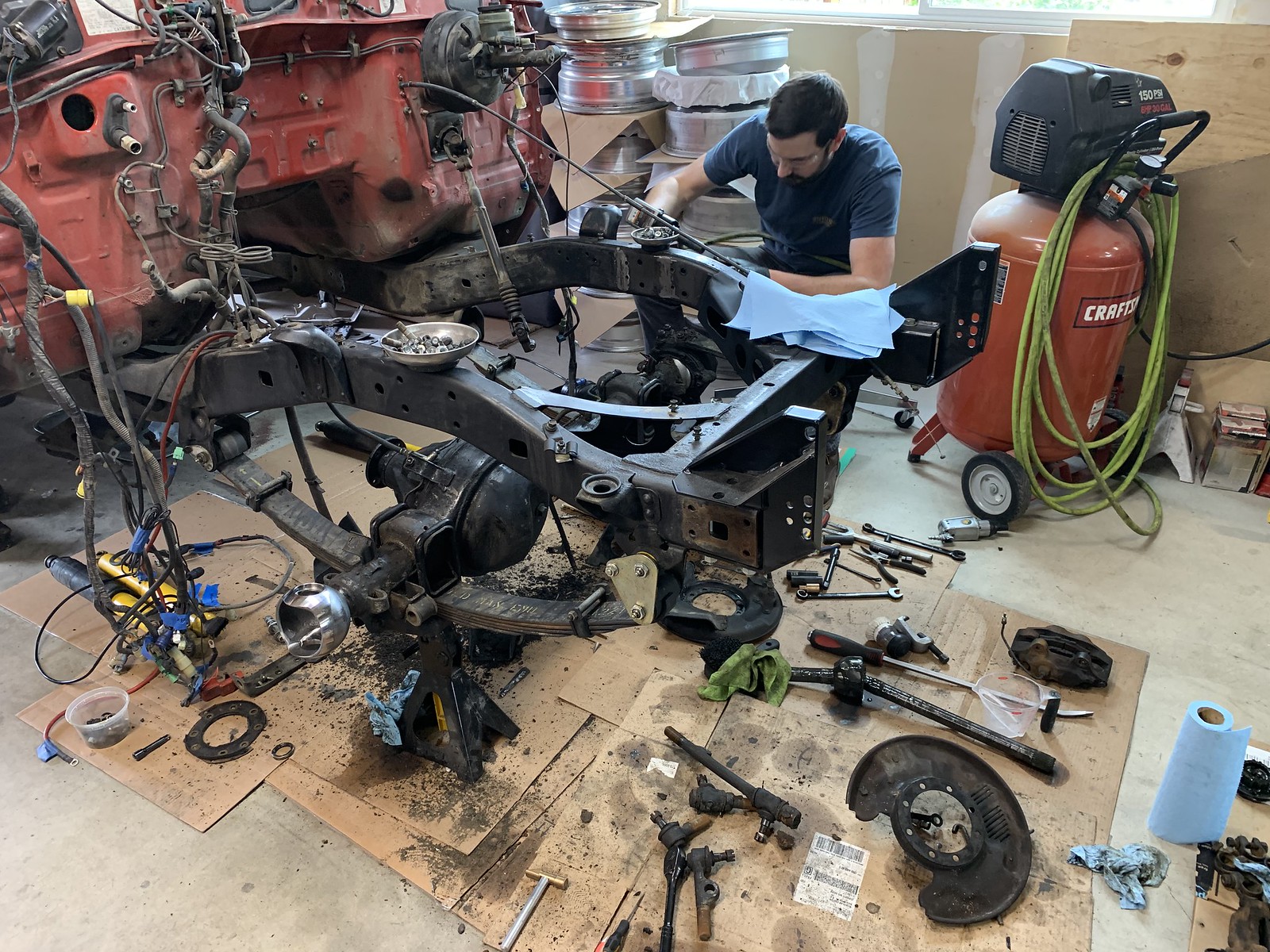

Knuckle rebuild and steering update started this weekend. Nothing spectacular to report. Things are slow. I just keep pressing along. Popped all the steering arms off and got the ends all off. Pressure washed the arms and will prepare them for a fresh coat of paint. Similarly, I tore down the passenger knuckle and started cleaning all the parts for a fresh coat. I also put on my Indiana Jones Fedora and started unearthing the axle. I felt like I was at an archaeological dig uncovering a T-Rex bone from the Jurassic period. Trying to devise a way to pressure wash it in my garage without making a mess. I have a fairly slopped driveway so I can't really push it out into the street as I wouldn't be able to get it in. Not a big deal though. Here's a few pictures, as is my status quo.

Need to do some caliper painting as well.

I'll take both sides apart so I only have to paint parts once.

I'll prod my way through the knuckles and steering stuff. I need to drop off my steering box at @torfab for a rebuild.

I absolutely recommend removing the engine, transmission, transfer case, radiator, hood, fenders, inner fenders and core support to do the knuckles. Makes things so much easier.

Need to do some caliper painting as well.

I'll take both sides apart so I only have to paint parts once.

I'll prod my way through the knuckles and steering stuff. I need to drop off my steering box at @torfab for a rebuild.

I absolutely recommend removing the engine, transmission, transfer case, radiator, hood, fenders, inner fenders and core support to do the knuckles. Makes things so much easier.

Last edited:

No lie. The parts guy put them in a sandwich bag.

No lie. The parts guy put them in a sandwich bag.