78fj40mg

TLCA #23510

Build and Upgrades Links:

- My Overhead Console Build

- Roof and windshield weather seals replacement

- Roof and windshield seals reference threads

- Remove Gear Shifter - How To Easily

- Heater and Blower Rebuild

- LED Tail Light Bulbs Install

- LED Front and Sides Light Bulbs Install

- LED Head Lights Install

- Pittman arm woes

- The nickel trick

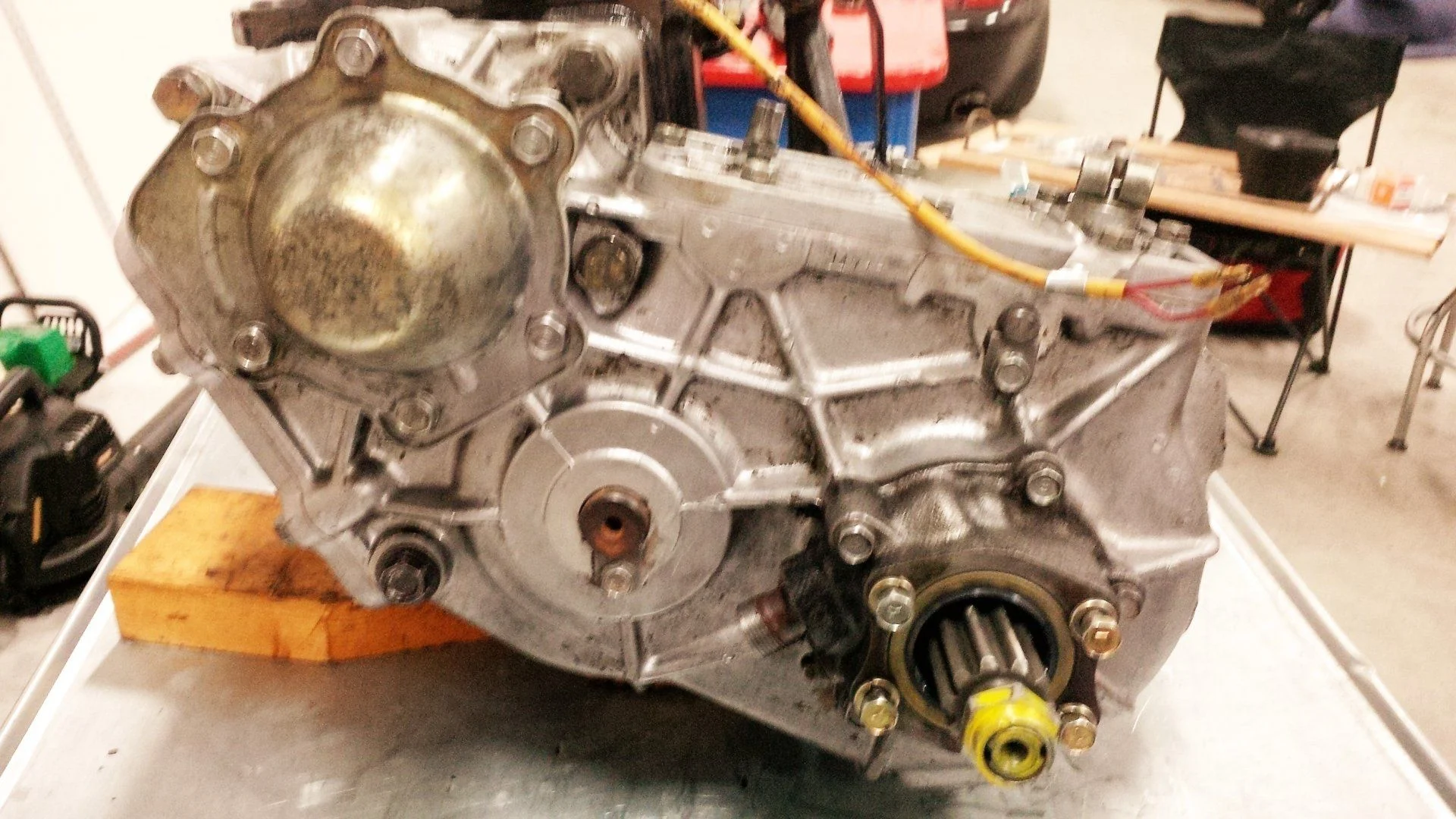

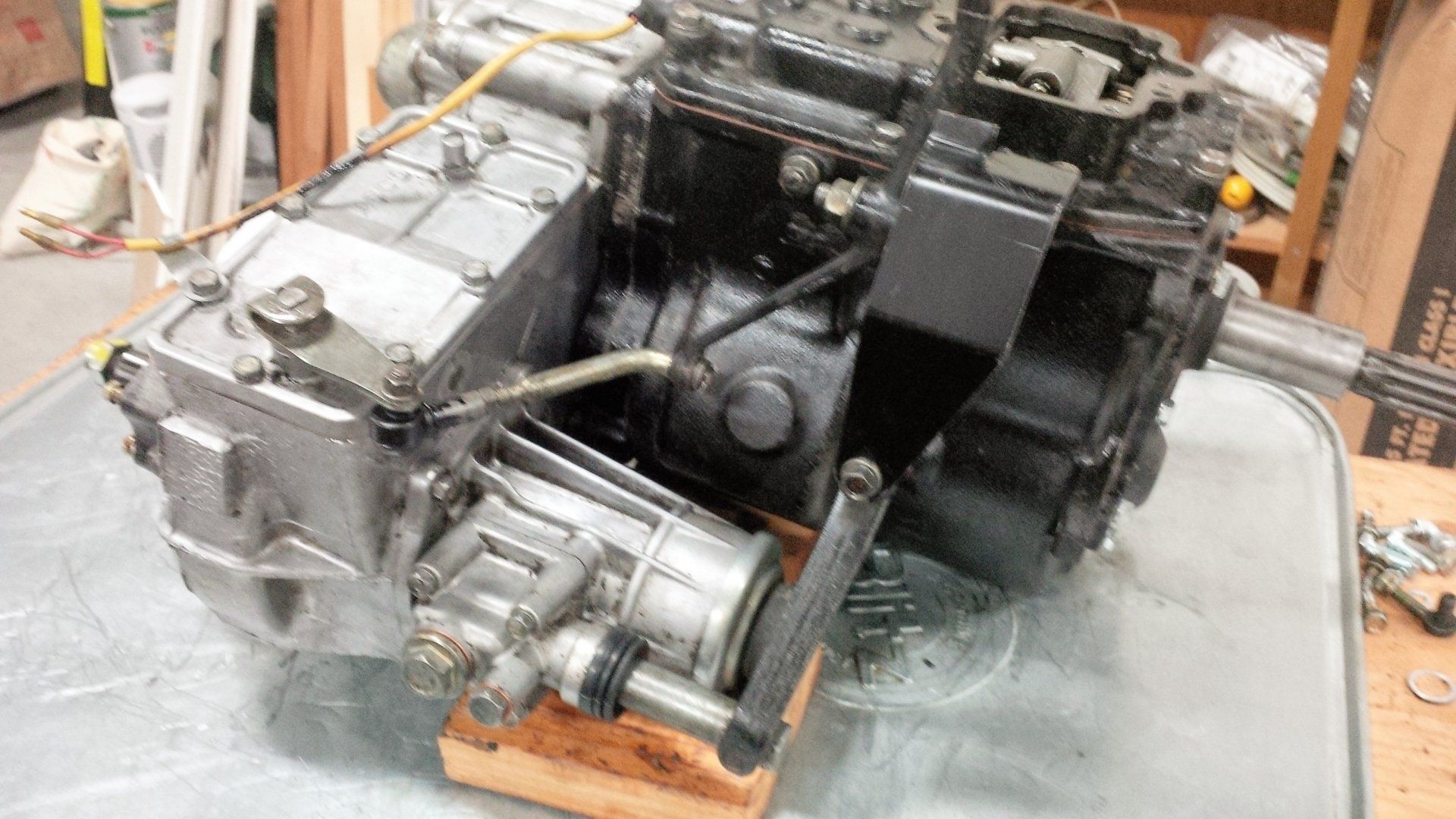

- Rear Differential Work and 3rd Member Rebuild

- Rear Disc Brakes Installation

- Rear Old Man Emu Leaf Springs Installation

- Front Old Man Emu Leaf Springs Installation

- New Steelies and Tires

- Steering Knuckles Rebuild

- Centering tool thread

- How To permanently Install a Zerk grease fitting to the steering knuckles

- Drive-line Angle Correction using shims

- Wood stove and chimney install in my shop to keep my FJ40 warm

- New Alternator Install

- The Evolution - The Toyota Land Cruiser History

Last edited: