78fj40mg

TLCA #23510

I've been wanting to add power steering for several years now and finally I pulled the trigger and purchased the required components out of an FJ60 from orangefj45 Georg @ valley hybrids.

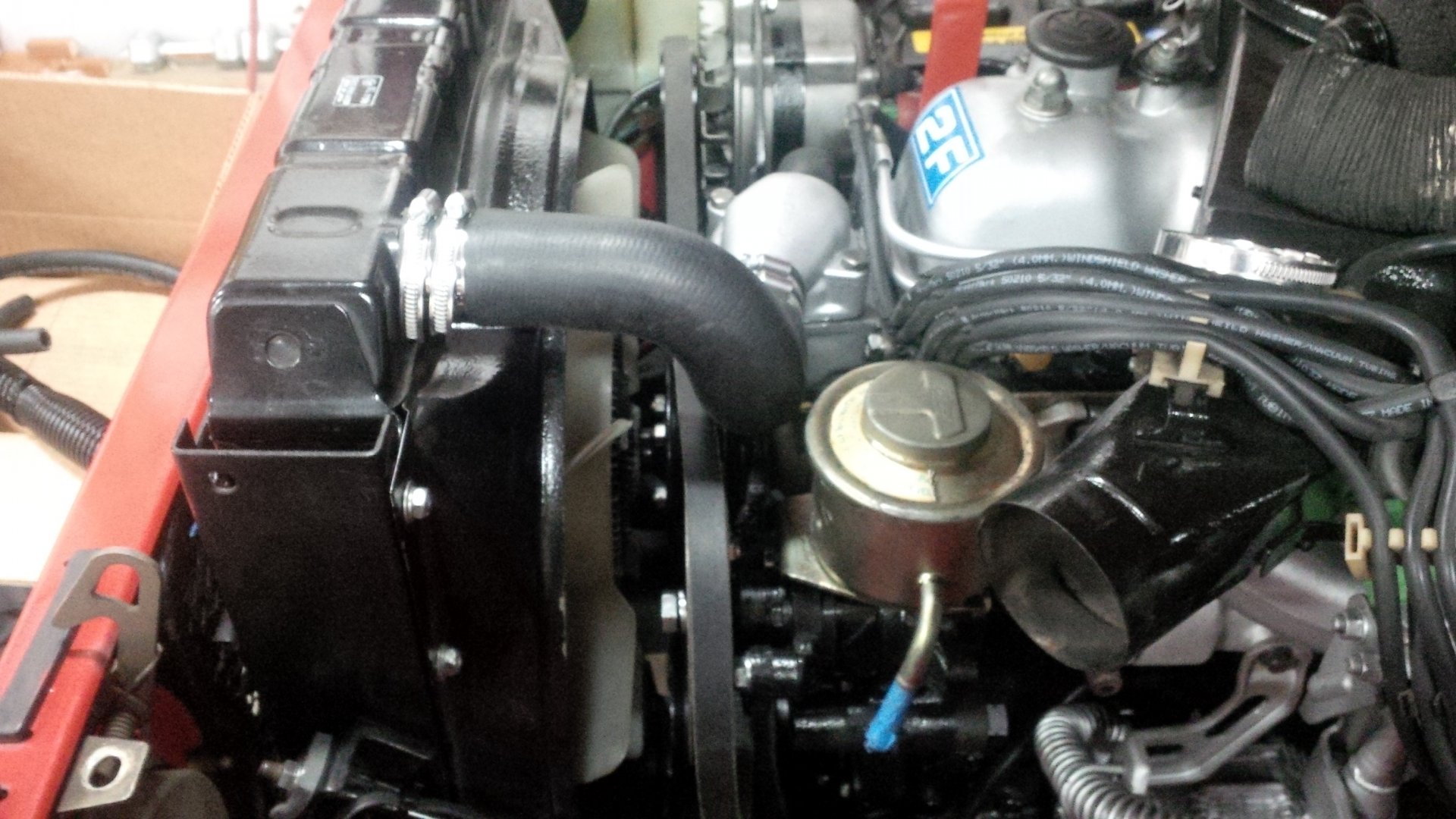

First installed the PS pump bracket which fits like a glove since my 2F engine has all the required threaded mounting holes for a seamless install, it looks factory.

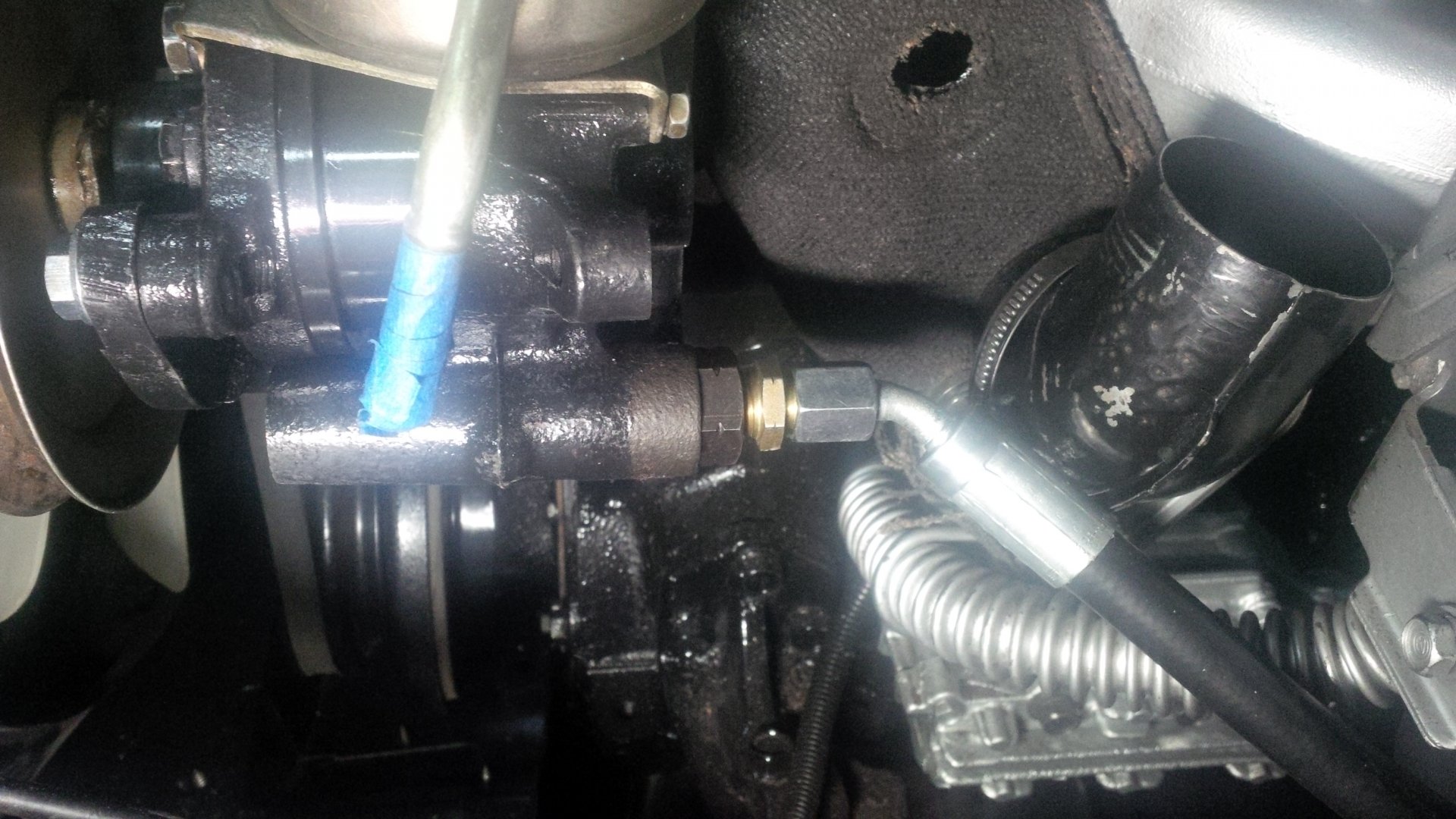

Next installed the PS pump and high pressure (supply) hose, the low pressure (return) hose will be connected down the road after I fab a cooling system for the ATF fluid which the PS system uses

The air intake heat riser had to be disconnected temporarily to facilitate the PS connections

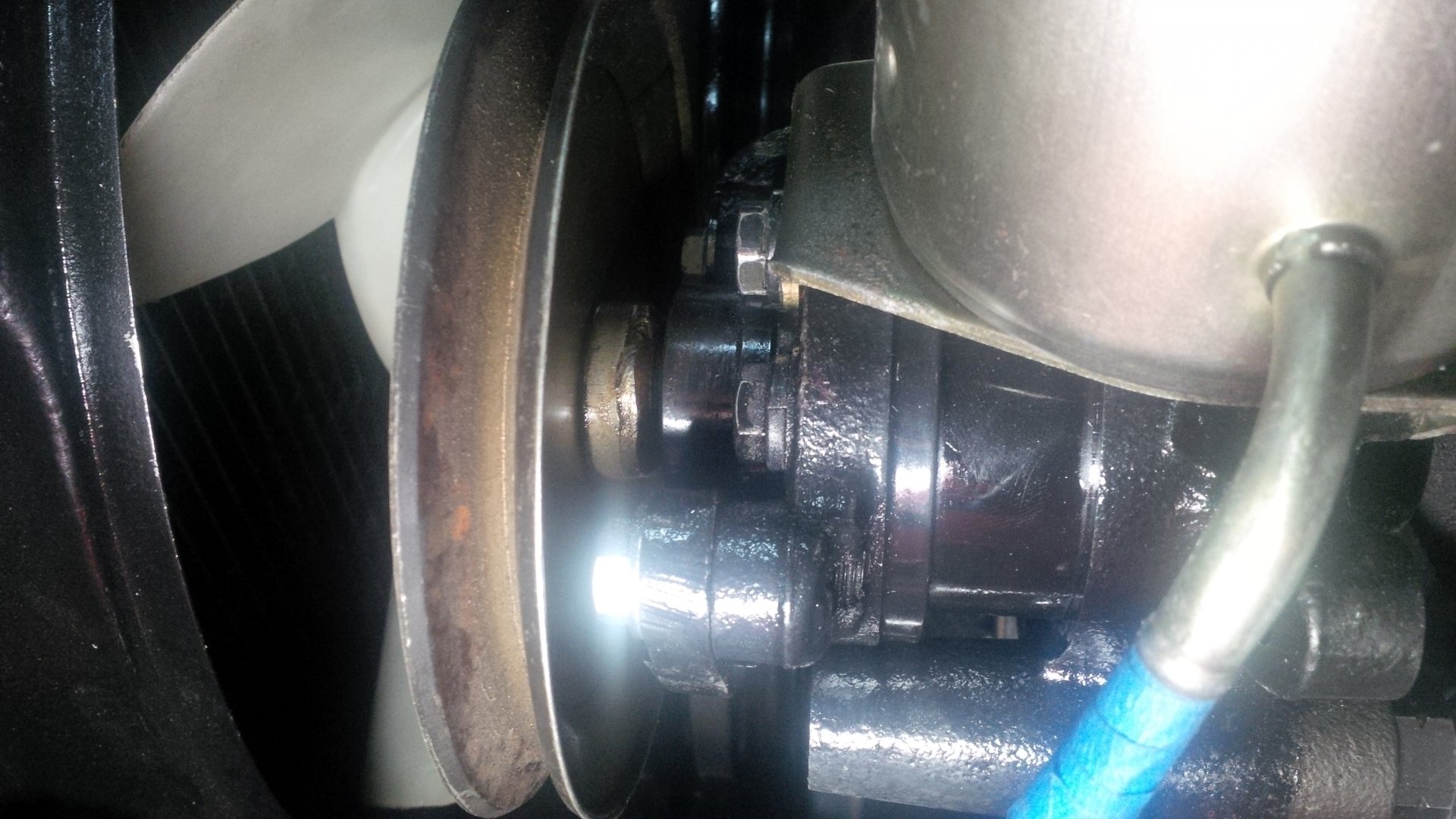

Also installed the PS pump pulley

Belts Clarification

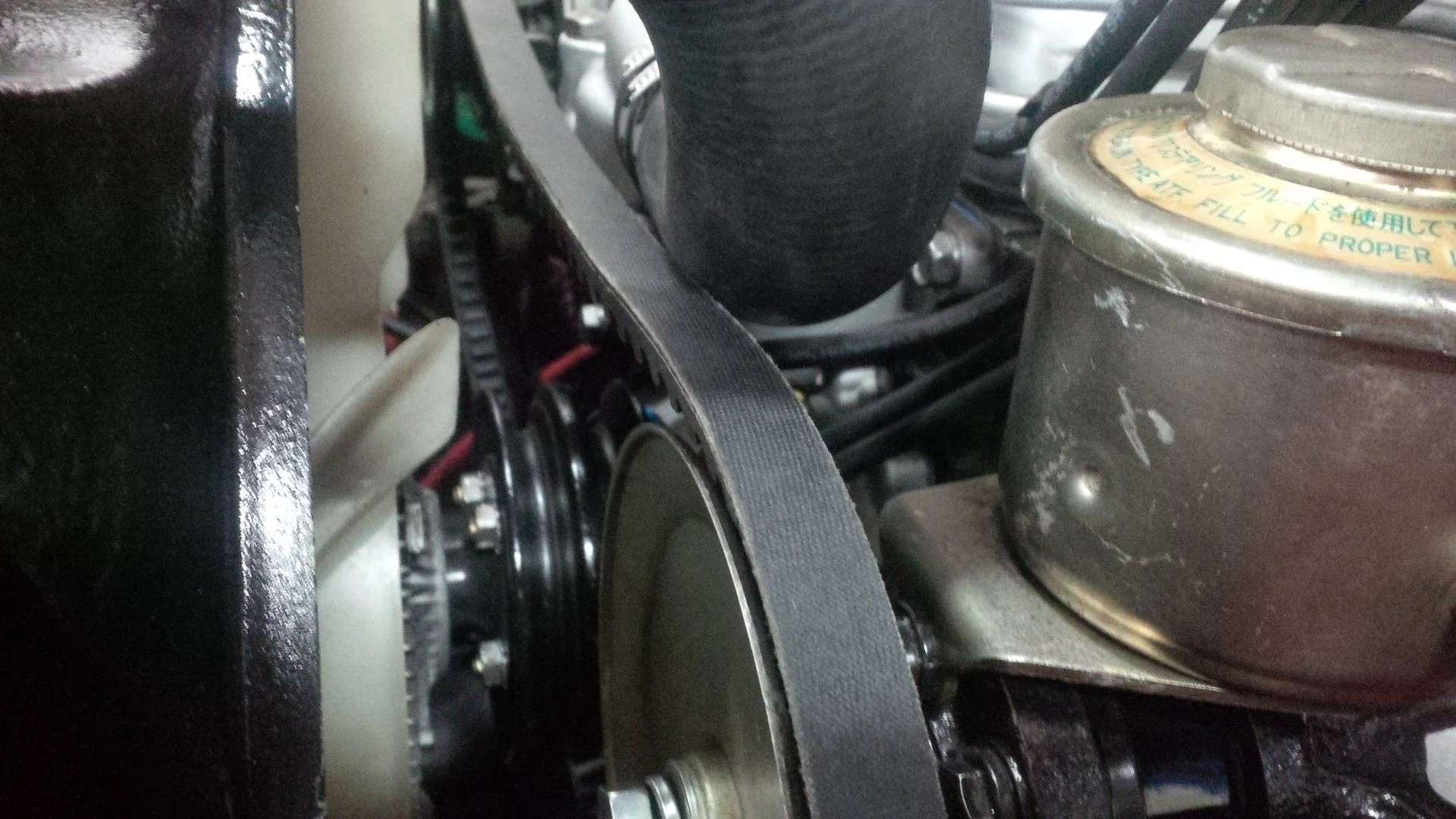

The belts will need upgrading for this install as follows:

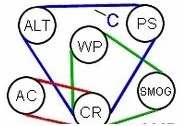

For the PS belt 'C' is required that drives the PS and alternator as depicted below, the alternator is the belt adjustment point.

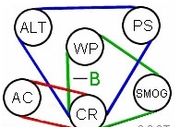

For the water pump belt a smog pump or an idler/adjustment pulley is required to install belt 'B' as depicted below, the smog pump is the belt adjustment point. A new 13 x 1060 belt will be used.

Since my truck came with a smog pump and associated bracket and hardware will be used it in this install, however, it will not be piped to the emissions system.

I will modify the air/smog pump to supply forced air into the carb air cleaner box, and install an air filter on the suction side of the pump to clean the air.

Piping system

I modified an old PS ATF fluid cooler to fit my 40 as depicted below;

I had to modify the cooler mounting bracket, this is the initial mock up it will be removed and painted prior to final installation and connections. This cooler is connected in series to the low pressure (return) piping system.

Next I will be removing the DS fender to allow for removal of the manual steering box and installation of the new PS gear box.

New PS gear box

To be continued

First installed the PS pump bracket which fits like a glove since my 2F engine has all the required threaded mounting holes for a seamless install, it looks factory.

Next installed the PS pump and high pressure (supply) hose, the low pressure (return) hose will be connected down the road after I fab a cooling system for the ATF fluid which the PS system uses

The air intake heat riser had to be disconnected temporarily to facilitate the PS connections

Also installed the PS pump pulley

Belts Clarification

The belts will need upgrading for this install as follows:

For the PS belt 'C' is required that drives the PS and alternator as depicted below, the alternator is the belt adjustment point.

For the water pump belt a smog pump or an idler/adjustment pulley is required to install belt 'B' as depicted below, the smog pump is the belt adjustment point. A new 13 x 1060 belt will be used.

Since my truck came with a smog pump and associated bracket and hardware will be used it in this install, however, it will not be piped to the emissions system.

I will modify the air/smog pump to supply forced air into the carb air cleaner box, and install an air filter on the suction side of the pump to clean the air.

Piping system

I modified an old PS ATF fluid cooler to fit my 40 as depicted below;

I had to modify the cooler mounting bracket, this is the initial mock up it will be removed and painted prior to final installation and connections. This cooler is connected in series to the low pressure (return) piping system.

Next I will be removing the DS fender to allow for removal of the manual steering box and installation of the new PS gear box.

New PS gear box

To be continued