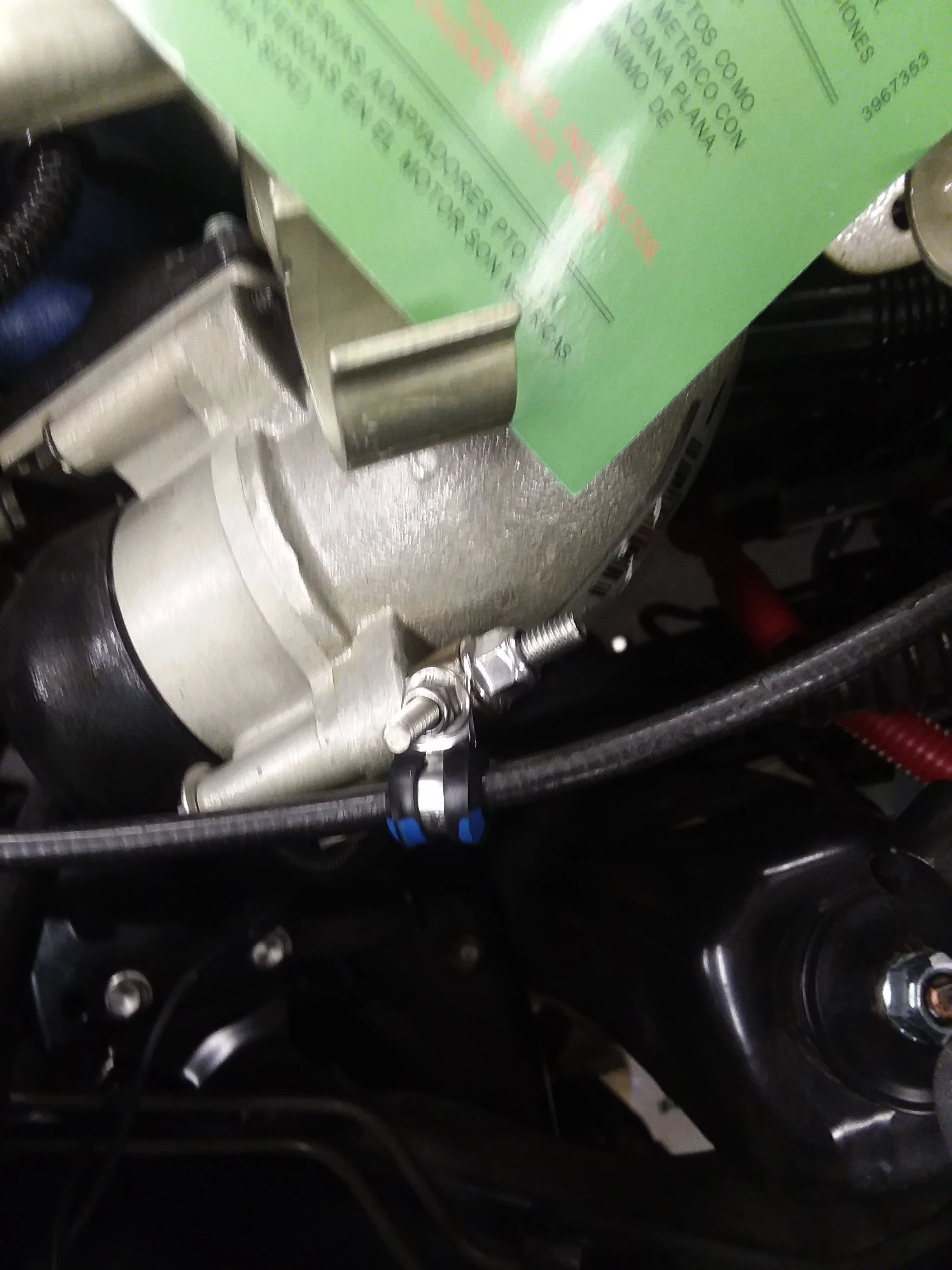

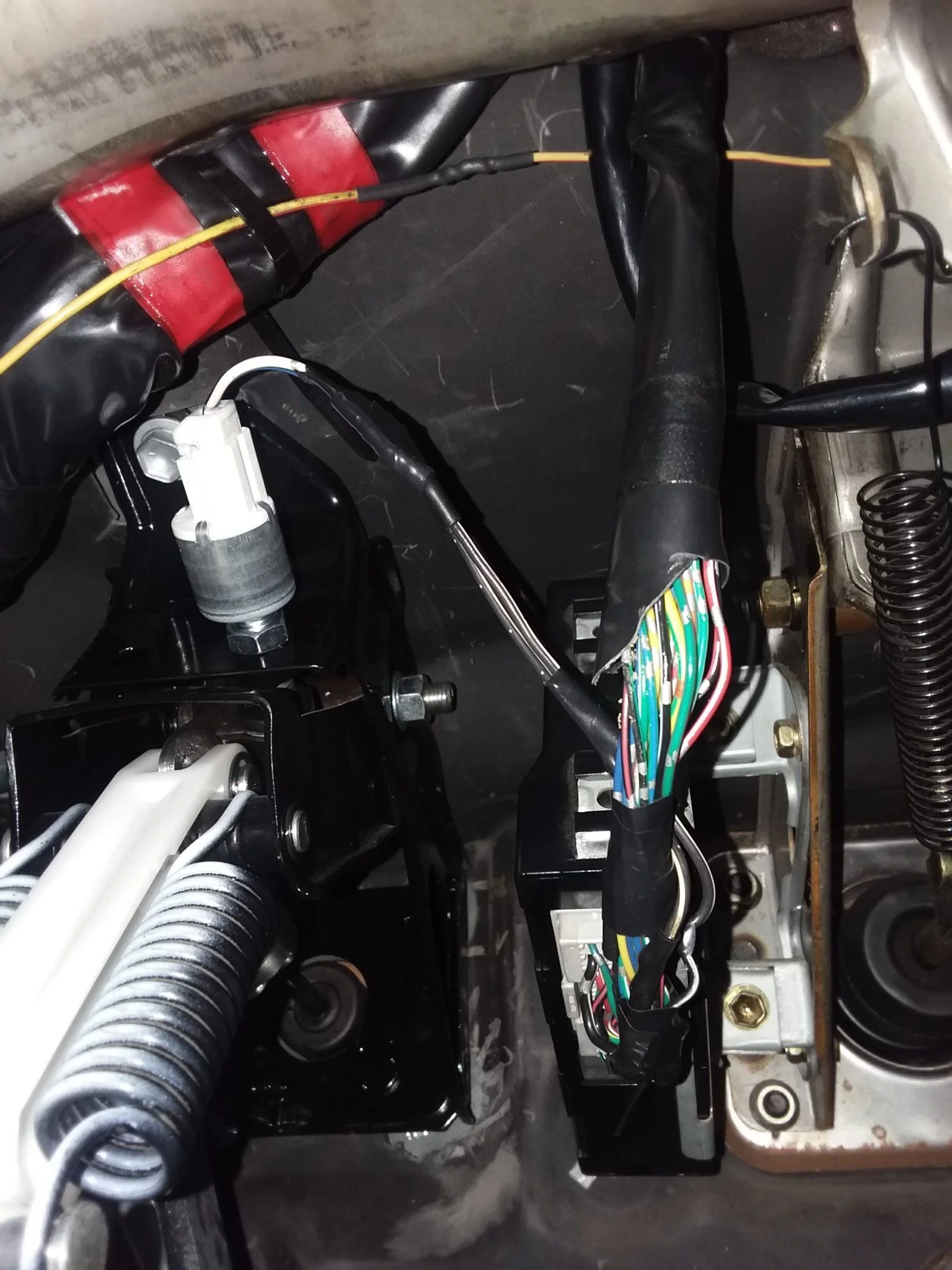

Cool info about the bump stops... I'd imagine the inboard stops are OEM. You could google the part number on them, but I'd assume you'll find they are Toyota parts.I investigated the bumpstops a bit today. I have been paying close attention to my oilpan clearance and I want to be sure that no accidents will occur down the road in the middle of nowhere.

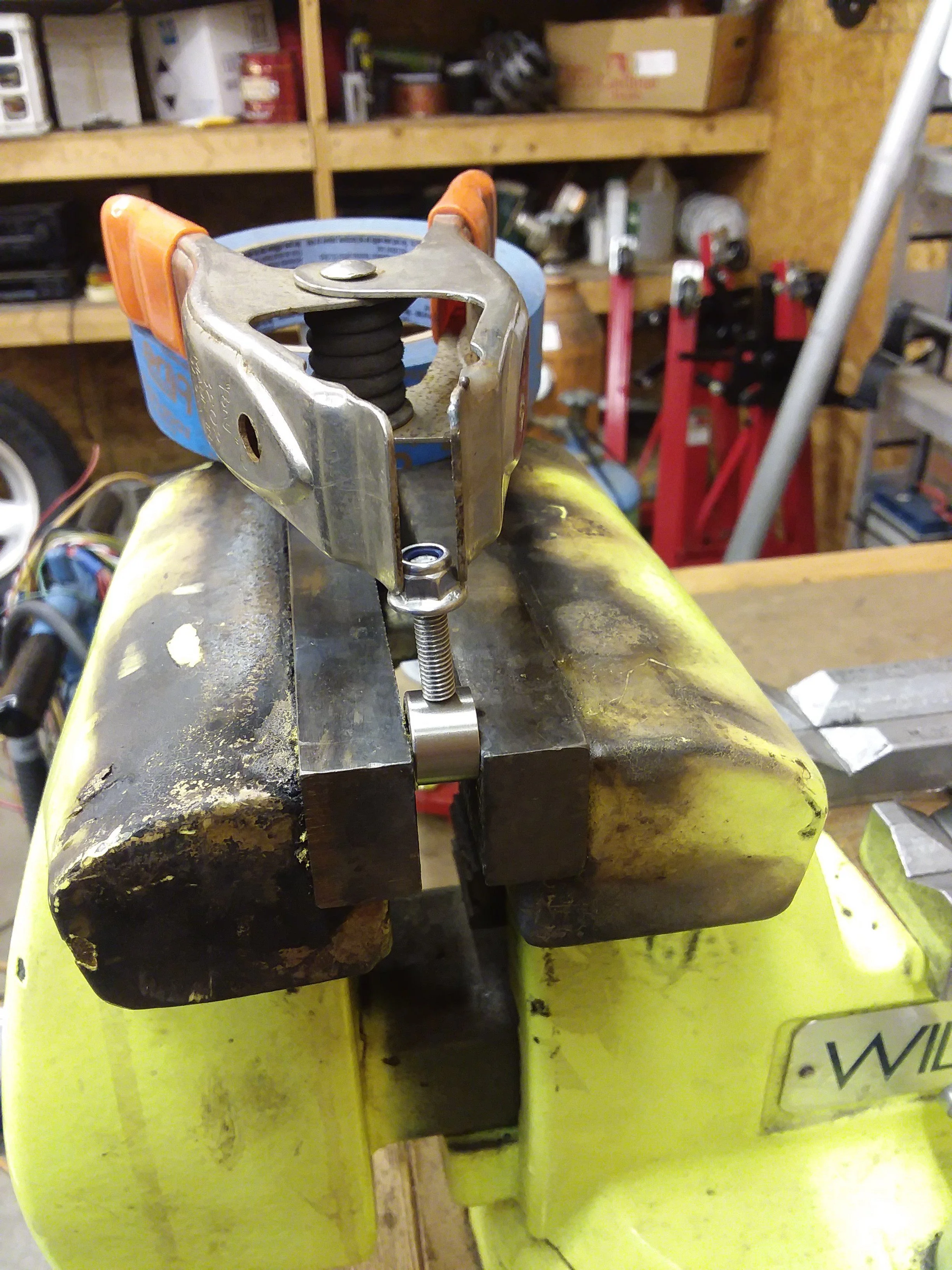

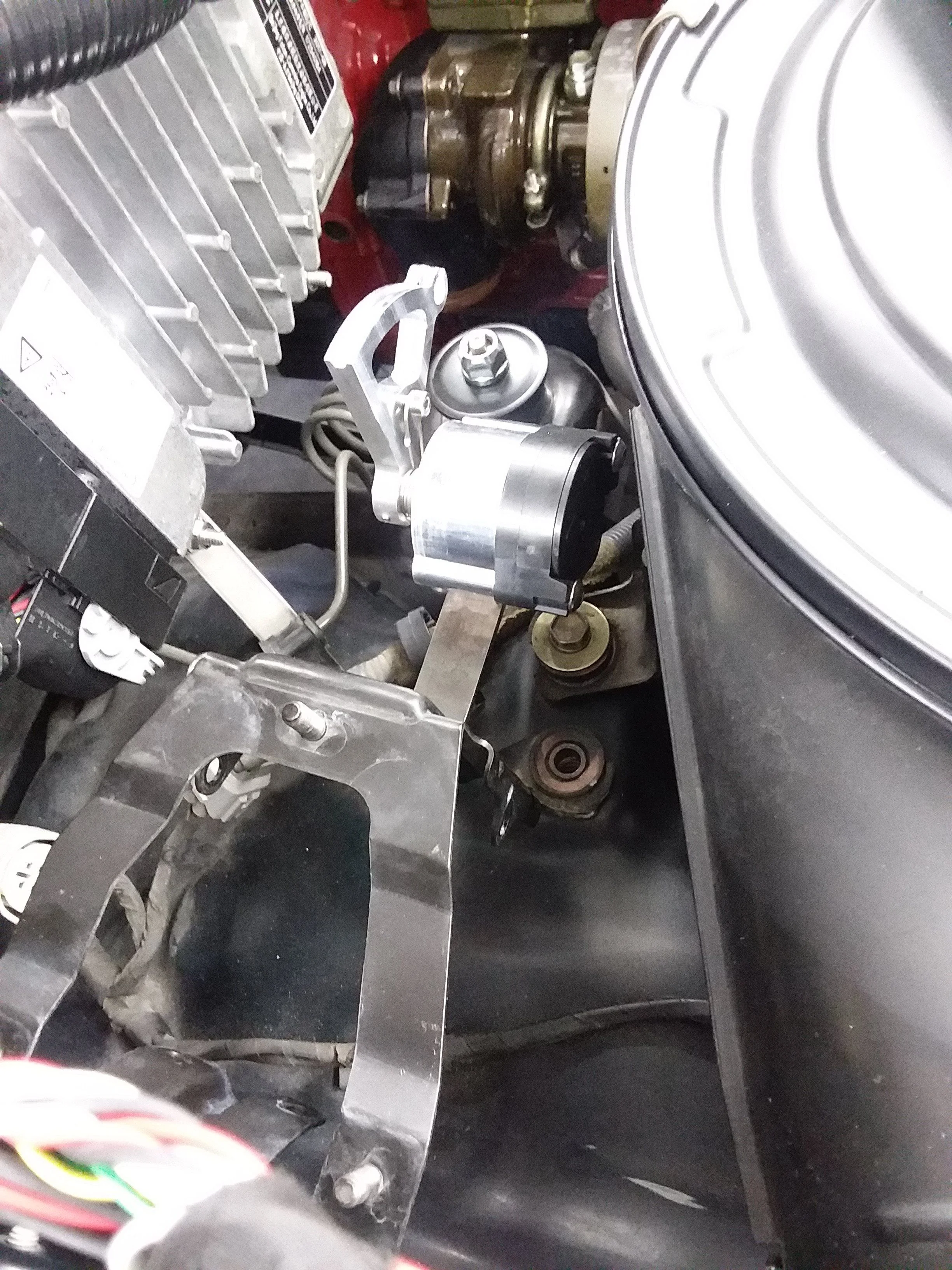

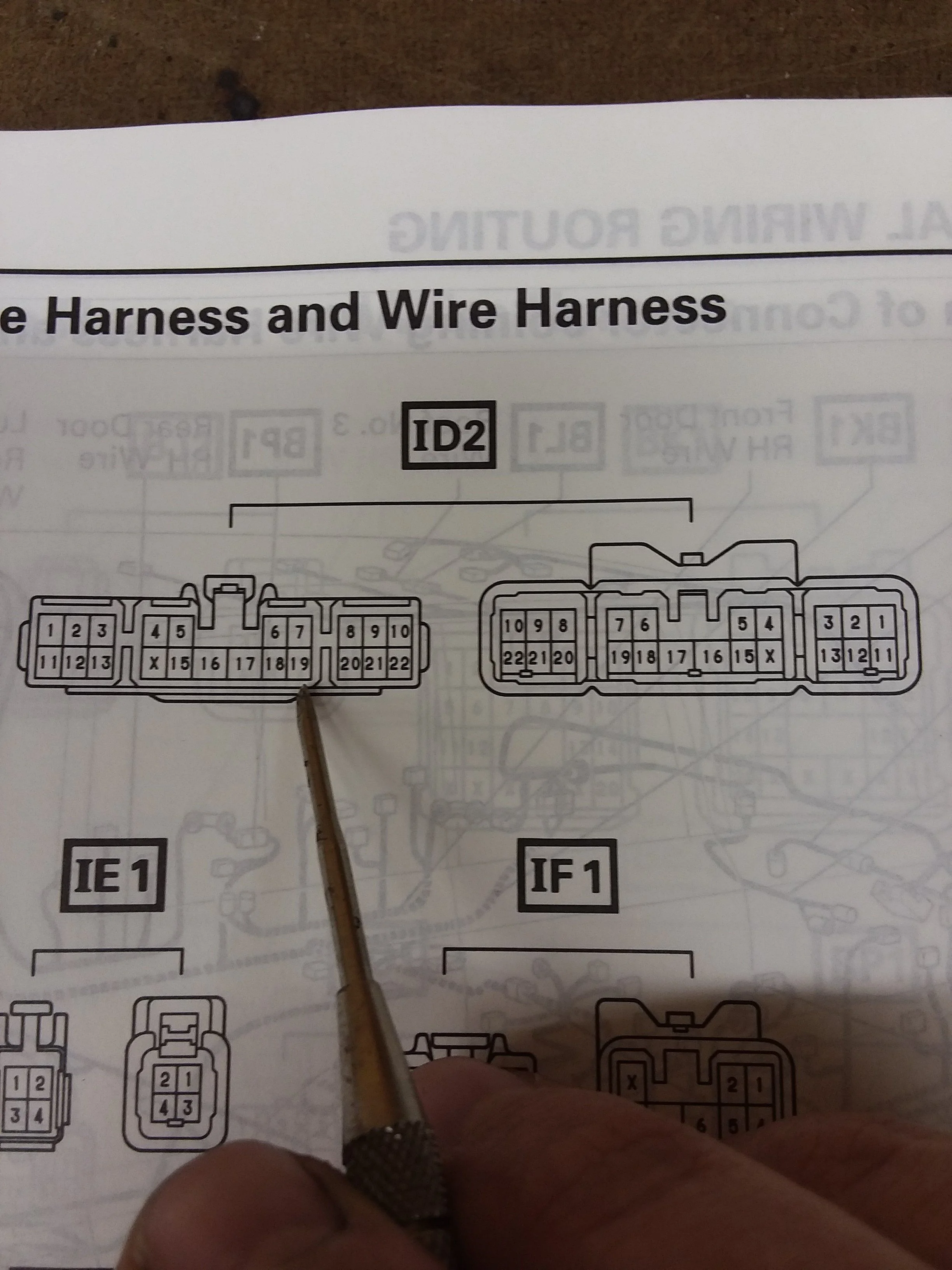

First, here are the inboard stops, they are not the same but both appear to have 10 digit part numbers on them, OEM?

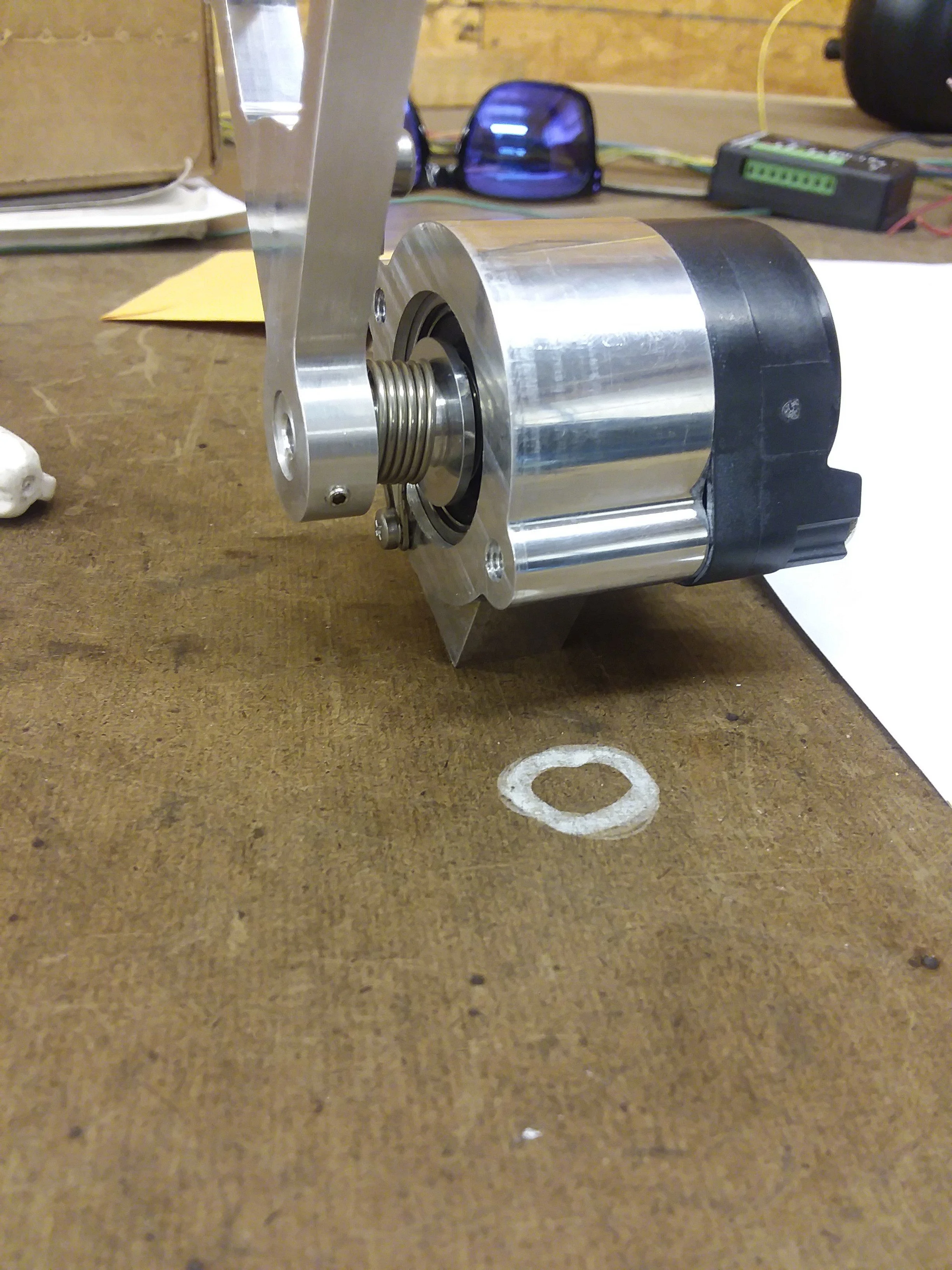

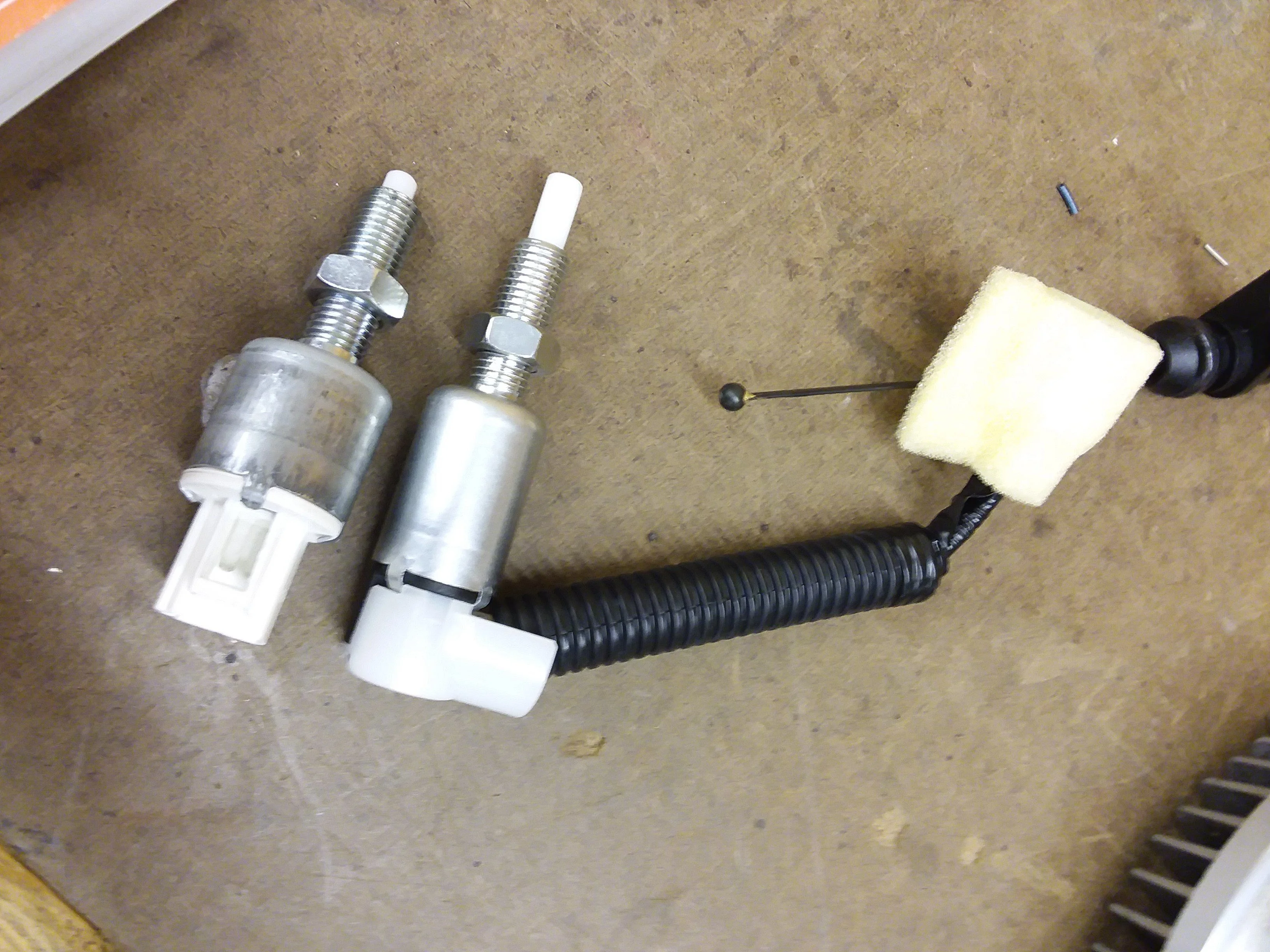

Here is an outboard stop with about 2000 pounds applied to it. My press guage is not accurate, the graduations are in tons, so I tried to get it to the first mark. Its a lot, you can see the the outboard stops really compress a lot, this has me worried.

The inboard stops are much stiffer...

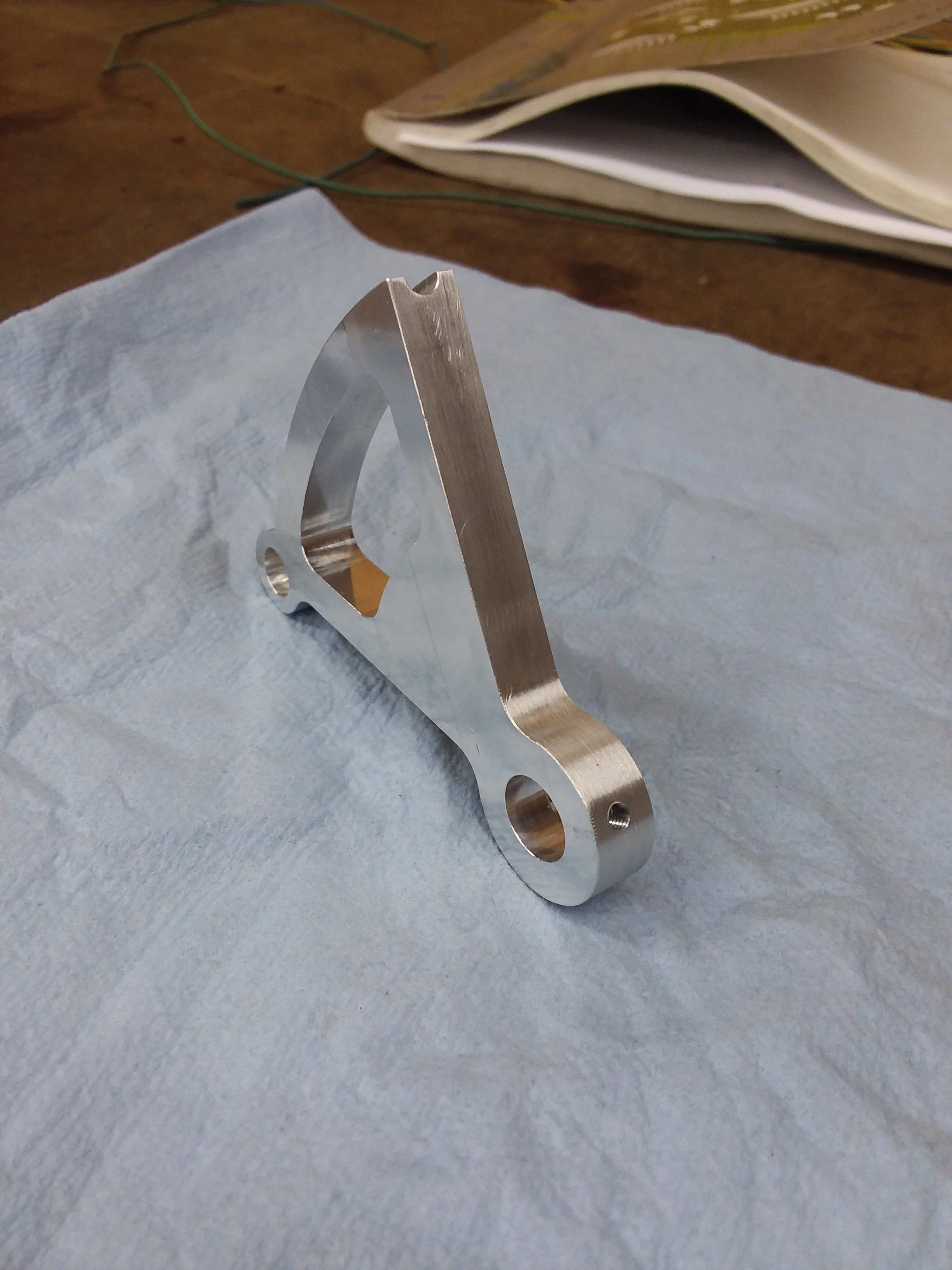

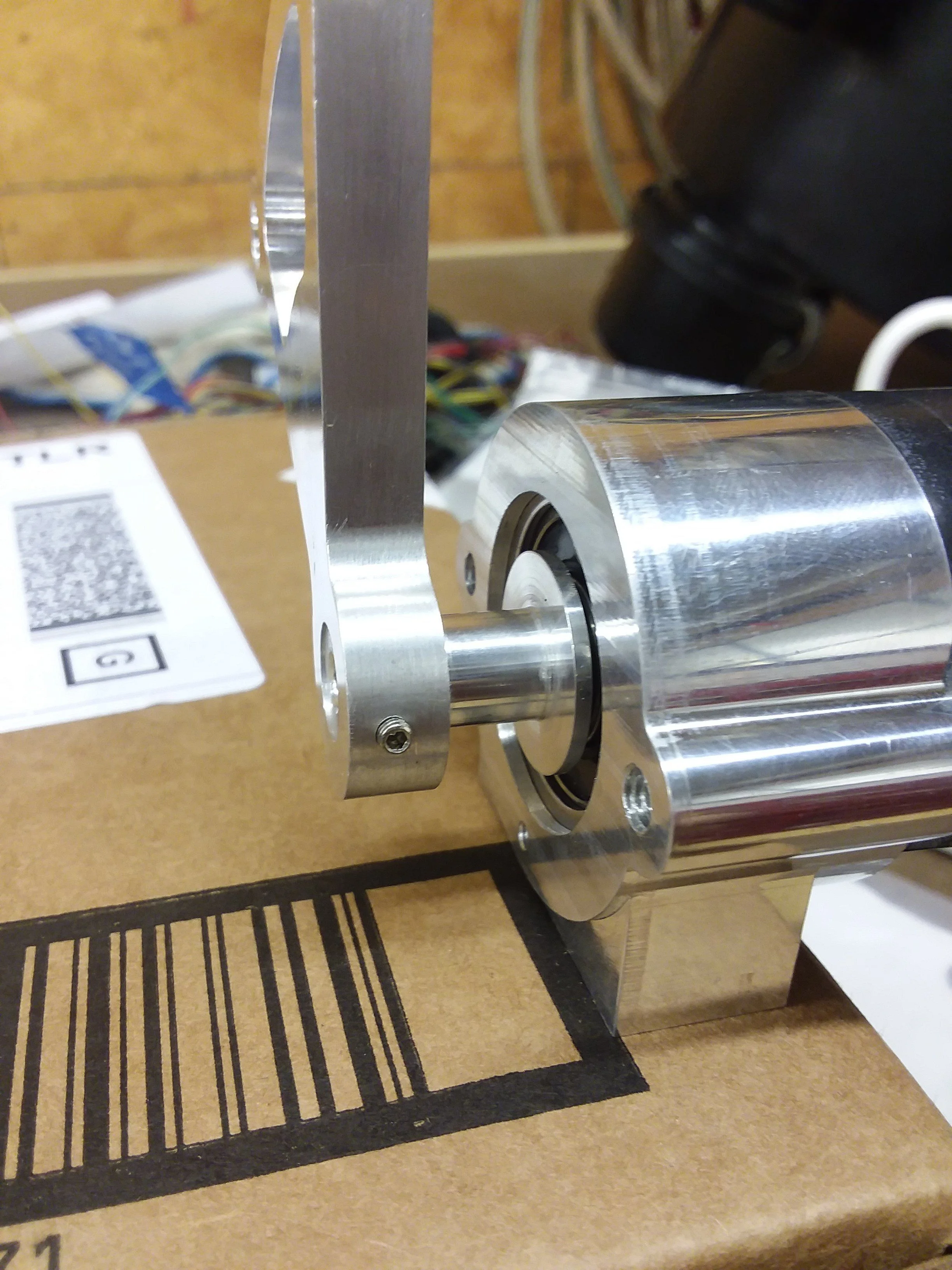

In a previous post I made the observation that the inboard RHS stop has about 1/2 inch of gap when the axle is touching both outer stops, meaning that my axle could possibly fit the oilpan if the right conditions were present. I think I am going to install 1 inch spacers over all of the bumpstops just to be sure that no contact occurs, and 1.5 inch spacer will be installed in the inboard RHS stop to make it the same as the LH one. Does anyone think this will cause any problems?

As for the spacers on the bumps, I don't think you'll have any issues as long as you still have sufficient up travel from ride height to not be hitting them all the time during normal driving. If you do have the up travel, it may also be worth spacing the primary (inside the coils) stops down further than the secondary ones so you get the softer, more progressive reaction from them before the firmer action of the frame mounted ones.