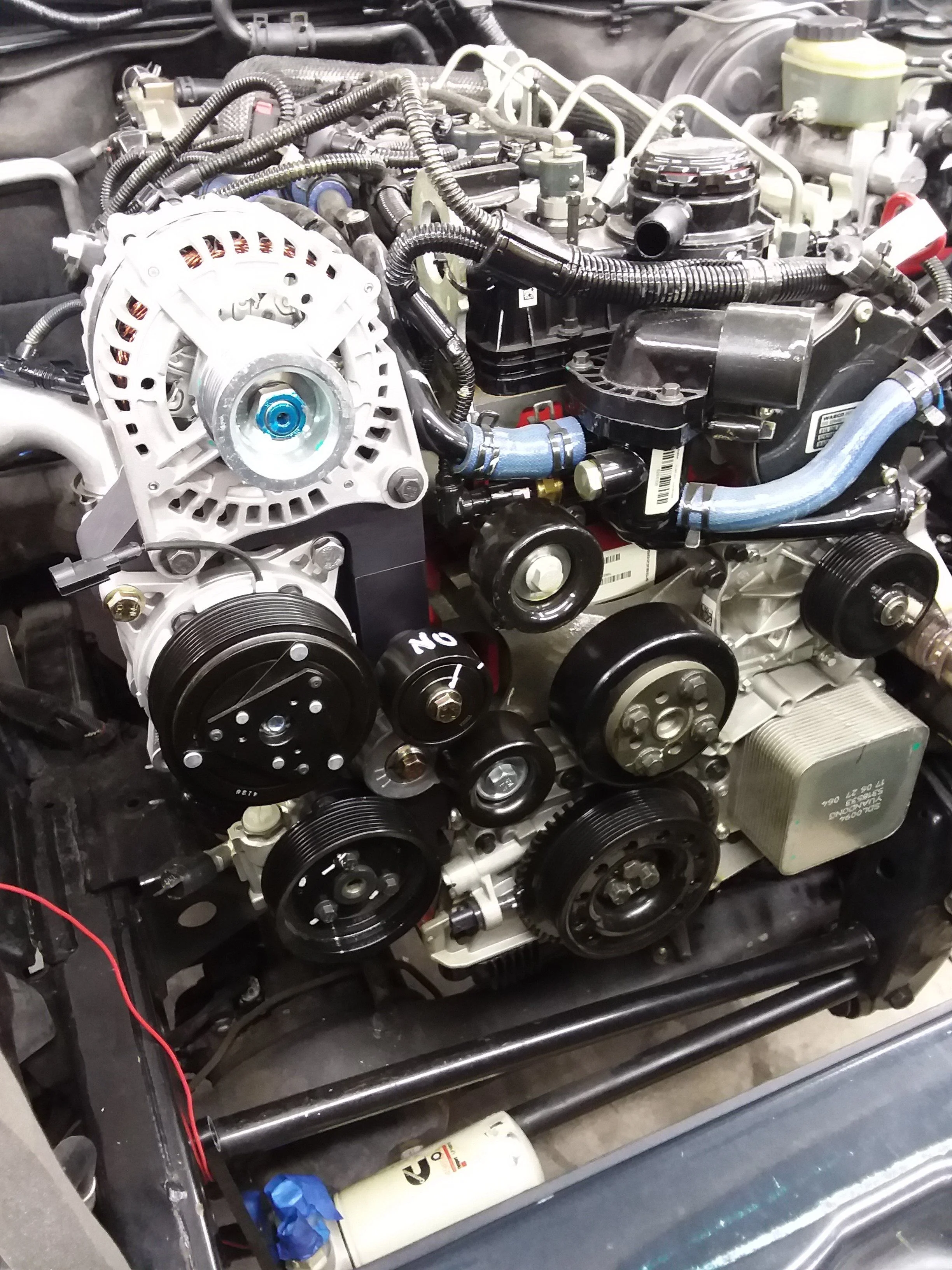

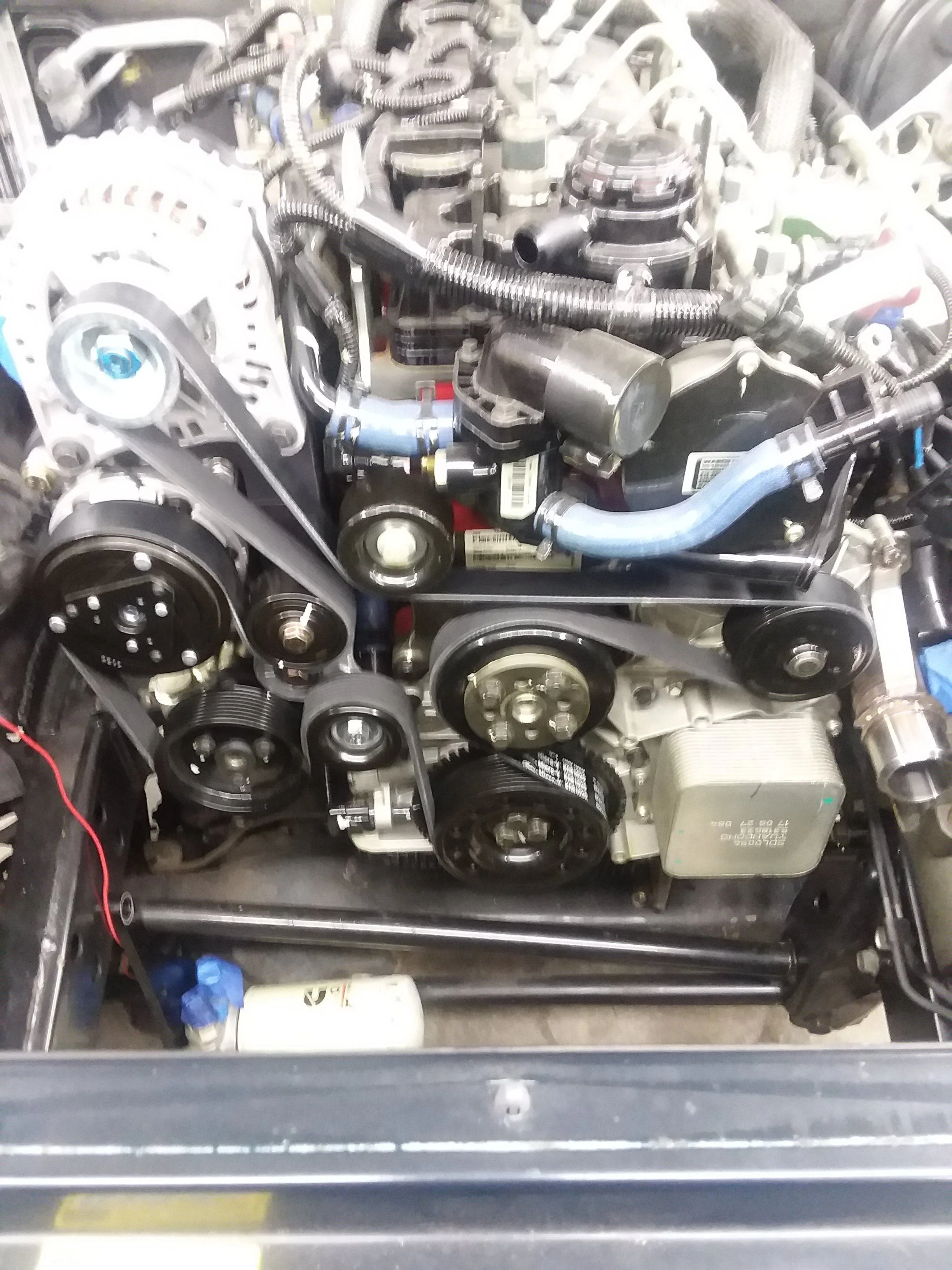

Its been awhile since my last update, not much has been going on. Waiting for a few parts to arrive. I have finally got the accessory drive done with the AC compressor installed. This was my one short cut on this project. I splurged for the extremely overpriced Axis Industries high mount mega bracket. Its a decent piece, it is lacking mounting holes to secure the wiring harness, that disappointed me very much given the price of almost 1400 dollars.

They also forgot to mention that the required serp belt is from a mid 90's MB S600 something with a V12, so don't think your just going to roll into Autozone and leave with one of those.

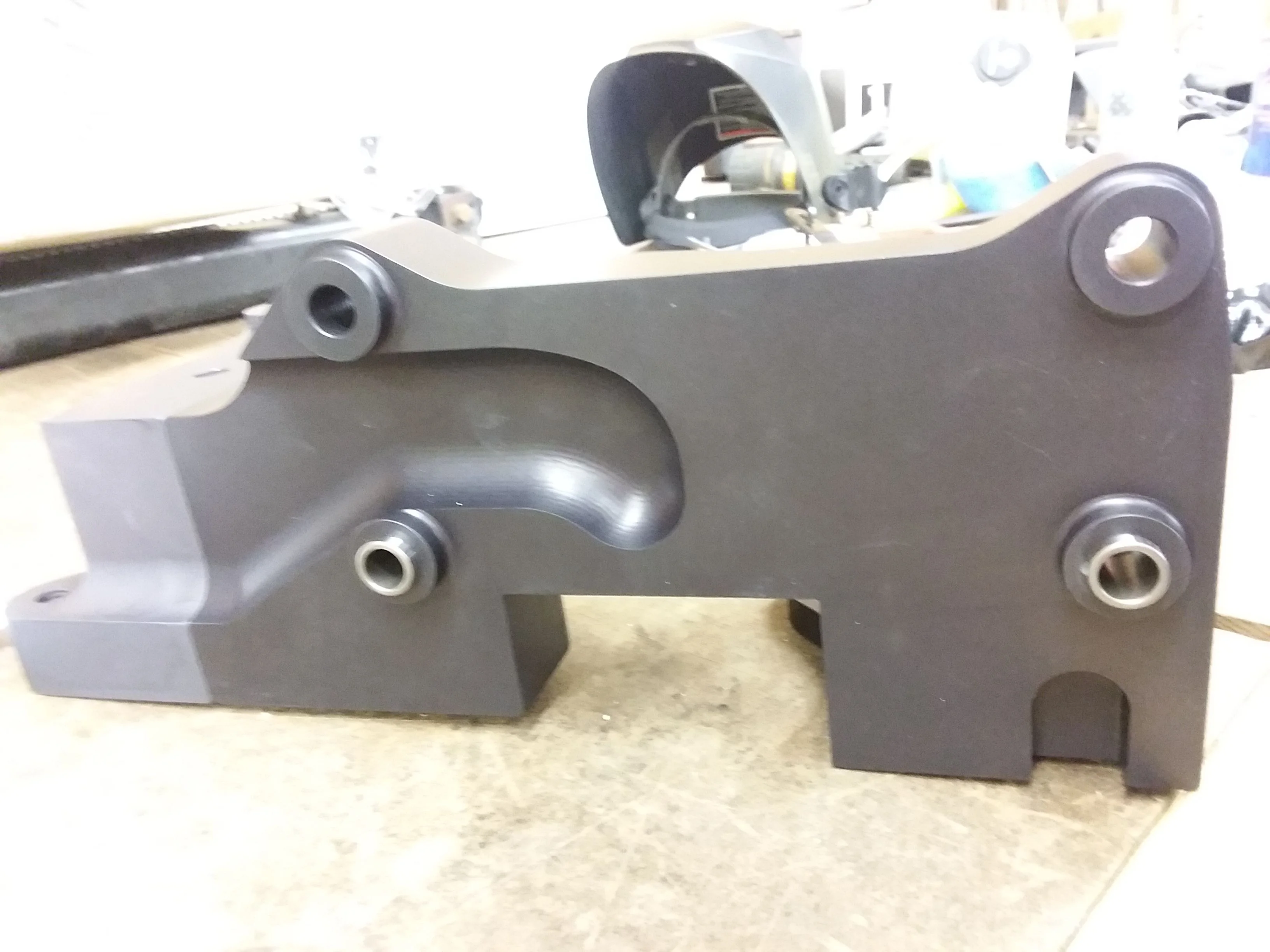

Here are a few shots of the actual bracket.

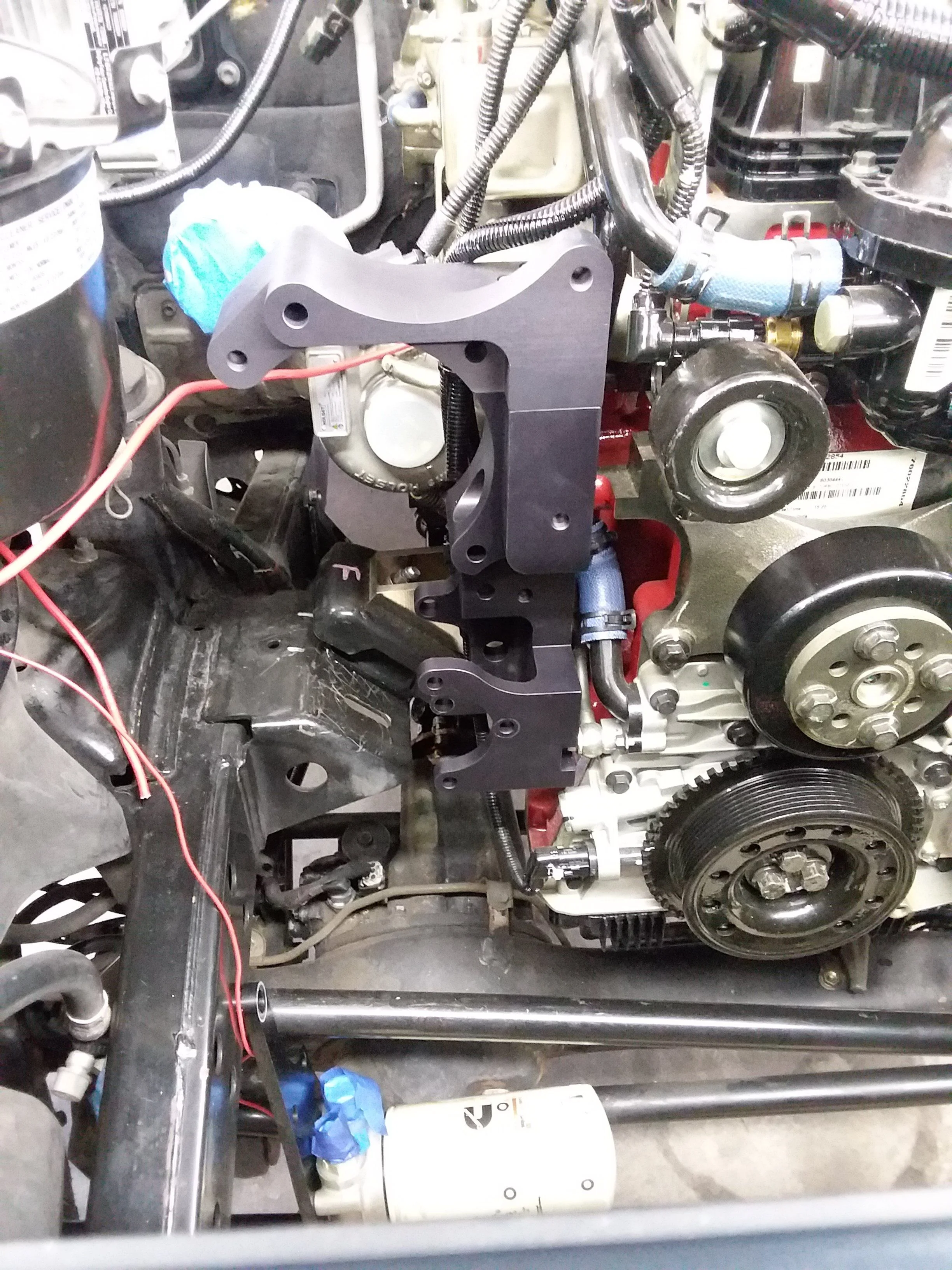

Mounted to cummins, it actually fits well. I was surprised...

Power steering pump installed

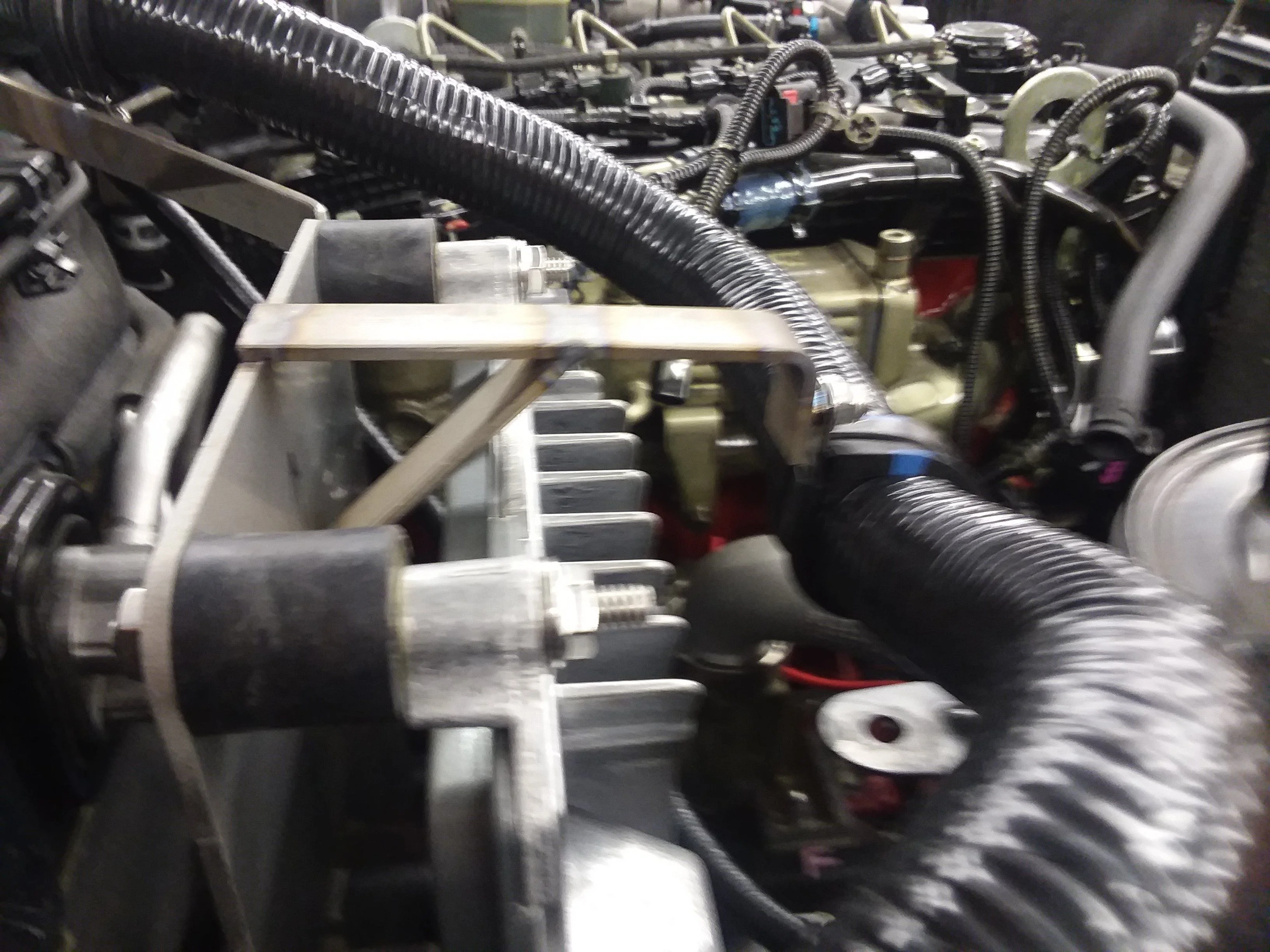

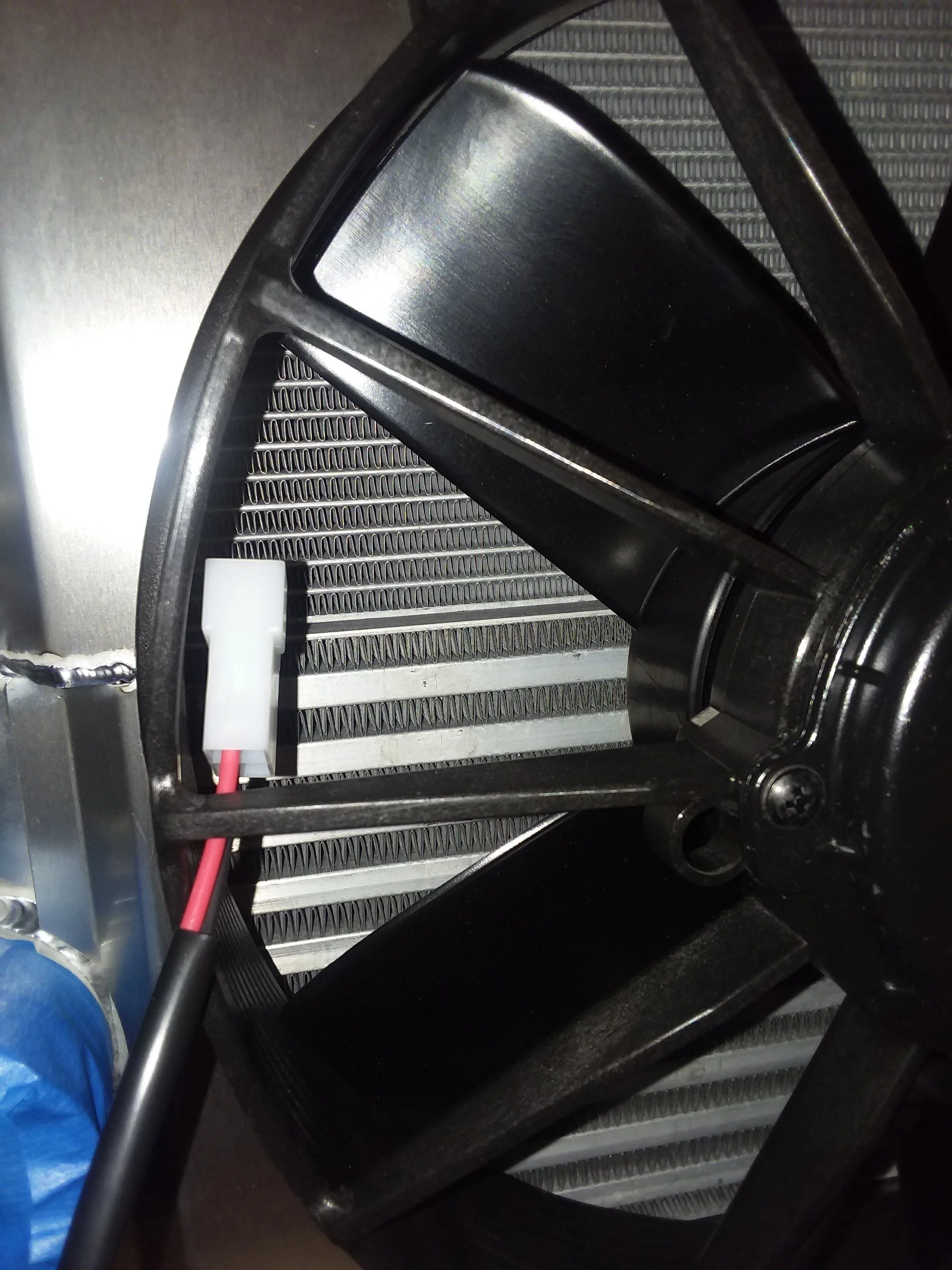

AC and alternator installed

Belt installed with Cummins AC spec tensioner

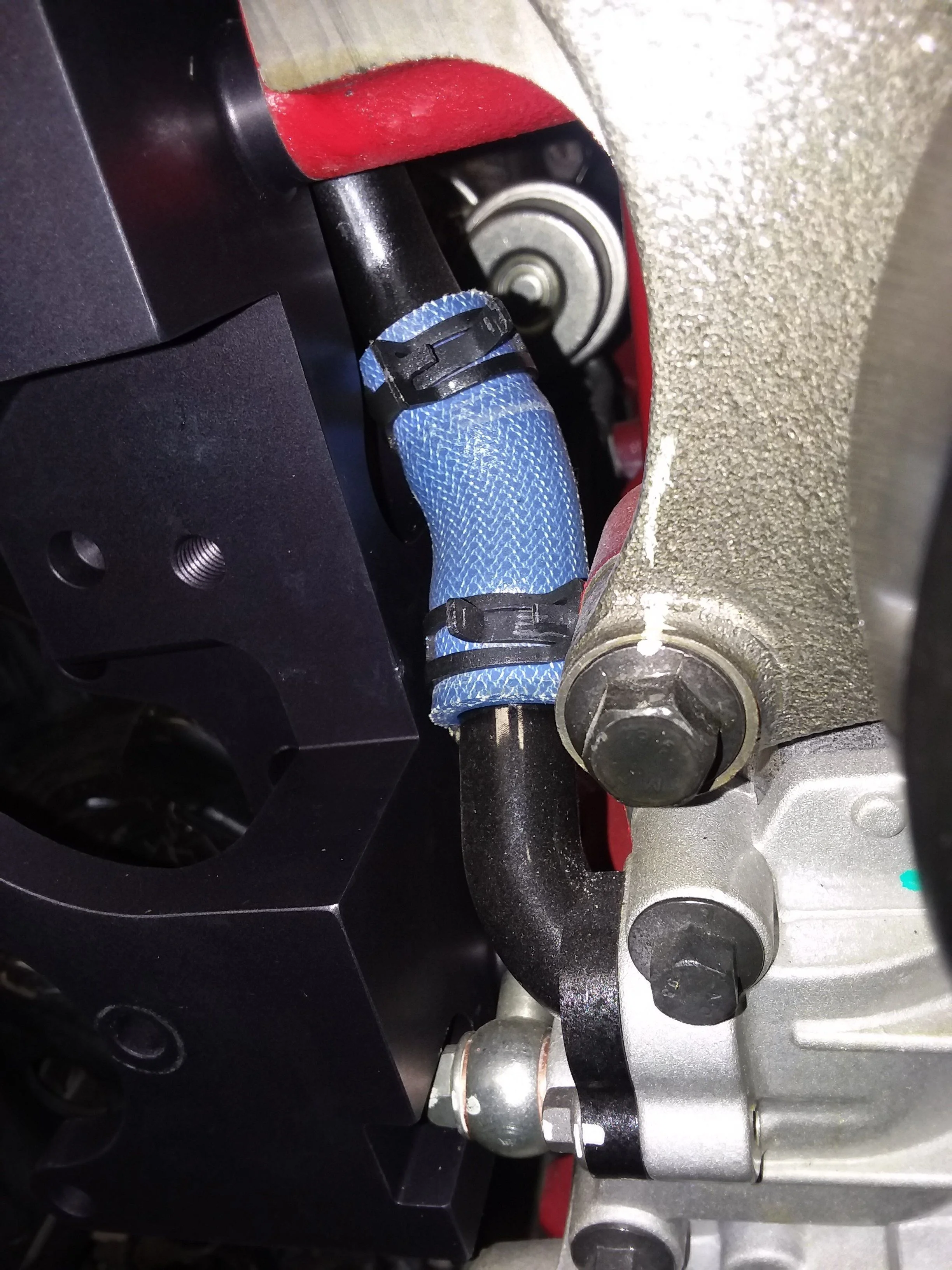

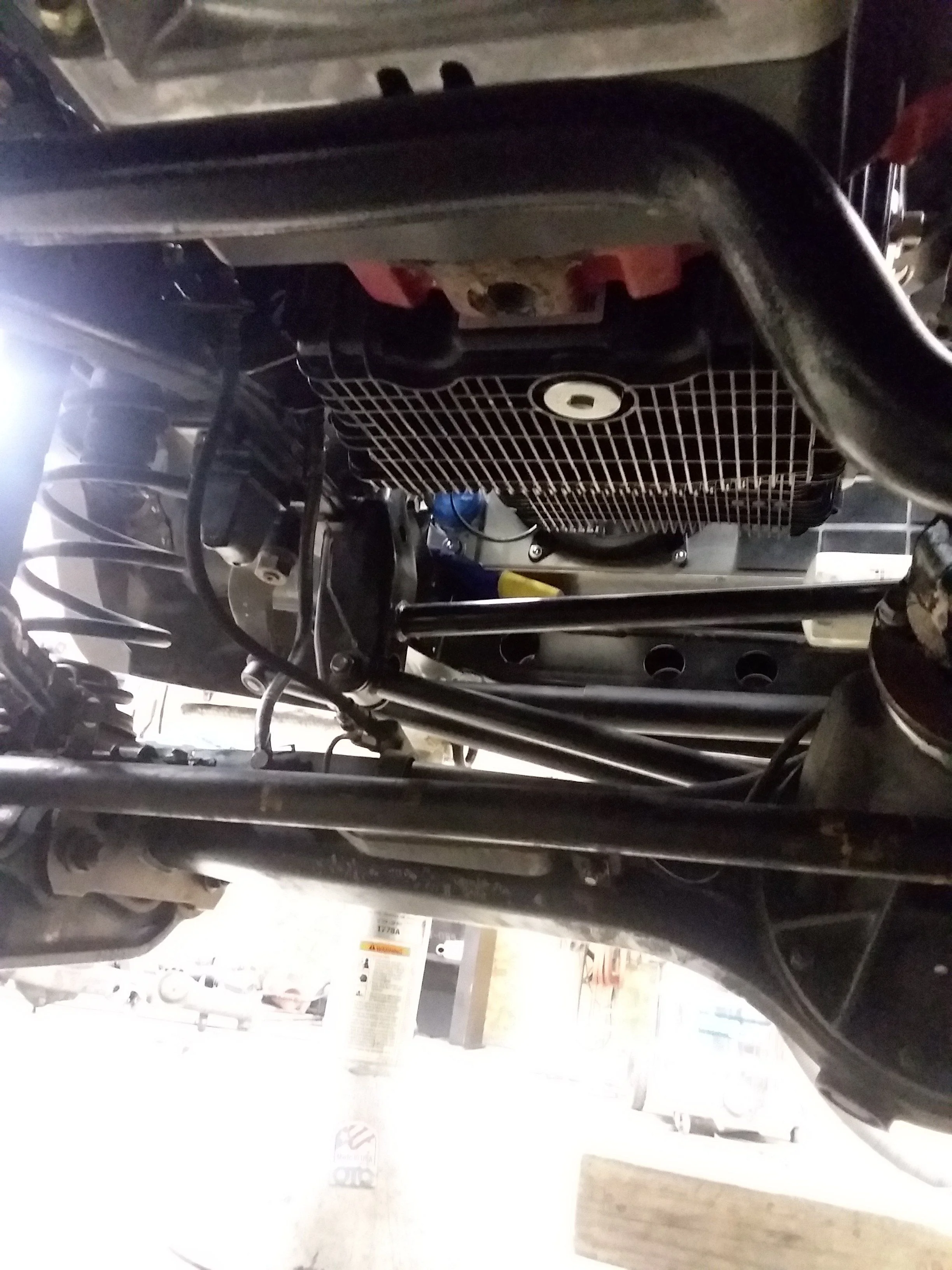

I guess I can consider this issue resolved, finally got the AC compressor to fit without any chassis cutting.

Does anyone on here know much about different steering setups for the 80 series platform? Is there an easy way to move the link that connects the two knuckles to infront of the axle?

Cheers!