Thank you immensely John, this was trail magic at its finest! It was all over too soon though. I carried the IPA you gave me all the way to zion to celebrate my completion of the Hayduke on observation peak!hike along the Hayduke.

A few hundred miles drive solo across backroads of the Colorado plateau, motivated by the opportunity to see an old friend - might just be the best way to rekindle my love affair with the old 40 series.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your Land Cruiser this week? (35 Viewers)

- Thread starter IH8MUD

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Wow, Mesa, I am way impressed. I just read about the Hayduke trail. Good for you!Thank you immensely John, this was trail magic at its finest! It was all over too soon though. I carried the IPA you gave me all the way to zion to celebrate my completion of the Hayduke on observation peak!

How long does planning something like that take? How often do you get resupplied? What’s your base pack weight?

https://forum.ih8mud.com/threads/the-hayduke-route-thru-hiking-thread.1268827/

Thanks, @Nothinghead it's all very fascinating really. I planned and obsessed for nearly 6 years till I went for it. John and I hiked the first 30 miles like 5 years ago when I passed the original briefcase to him with both our 83" 40's.

I go 2-10 days between resupply. My base weight ranges typically between 12-14 lbs. Get some popcorn and a cold beer

and a cold beer and go check out my thread, and start from the beginning!

and go check out my thread, and start from the beginning!

Thanks, @Nothinghead it's all very fascinating really. I planned and obsessed for nearly 6 years till I went for it. John and I hiked the first 30 miles like 5 years ago when I passed the original briefcase to him with both our 83" 40's.

I go 2-10 days between resupply. My base weight ranges typically between 12-14 lbs. Get some popcorn

and a cold beer

and a cold beer and go check out my thread, and start from the beginning!

and go check out my thread, and start from the beginning!3sp out! That's all I did. The rest will come soon.

Adarcy

SILVER Star

Drained the transfer case, fixed it’s leaks, and refilled it, then replaced the reverse light switch in the transmission. I can finally see backing up at night!

Next up is figure out why my turn signals have stopped working

Next up is figure out why my turn signals have stopped working

rex in bama

SILVER Star

Lol. If a drive is post worthy surely it’s pic worthy, no?Pictures of what, the traffic or the post office?View attachment 3177980Turning around in the driveway.

In spite of the fact that it used to cost money to get film developed and it took days to weeks to get the pictures I have stacks of them that I never look at.Lol. If a drive is post worthy surely it’s pic worthy, no?

Grabbing the camera to take a trip to somewhere I have been many times just doesn't occur to me.

Sorry I am such a disappointment.

www.istockphoto.com

Vossie

#thecrazycruiserman

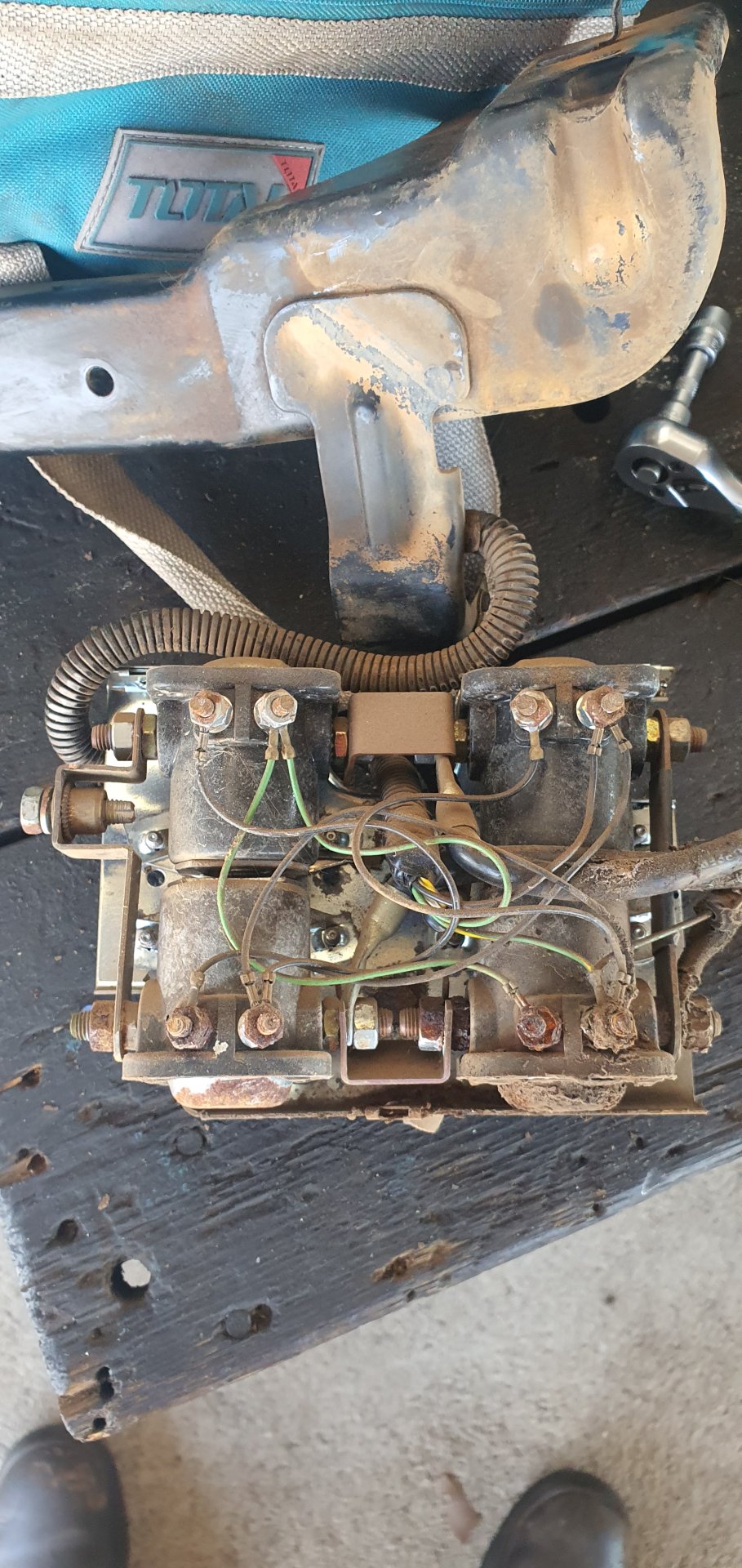

Picked up a new to me warn, think it's a M8000, if someone can help confirm?

Diagnosed why it only works one way. Need to find a new solenoid.

Did some small jobs around both the cruiser and the Mrs surf

And stole some new style single peice doors that are going to need alot of love! Could be worse though!

Diagnosed why it only works one way. Need to find a new solenoid.

Did some small jobs around both the cruiser and the Mrs surf

And stole some new style single peice doors that are going to need alot of love! Could be worse though!

Very nice! And the garage is really nice! I've been looking for something similar (I think).Just took my BJ out of its shelter and did a little test drive. I'm waiting to get into my new garage (behind), few more weeks…

View attachment 3178515

Are you building the garage from plans, or is it a custom design? I want something very similar to what you have.

- Joined

- Nov 6, 2006

- Threads

- 65

- Messages

- 1,650

- Location

- Boulder County, Colorado

- Website

- www.adventuretoolcompany.com

Replaced the 53 year old clutch slave cylinder and (3) heater hoses in our 69 Pig, also known as the "Working Pig" since it's been a plow truck since 1971!

Installed at set of Koito H4 headlamps.

I still need to update my battery cable clamps for ones with accessory mounts to install the dedicated wiring harness. But even without the harness improvement in lighting is noticeable.

Of course while aiming the headlights, I noticed a front side marker light was out. So the FJ40 to do list remains in balance.

Working on the bench due to season.

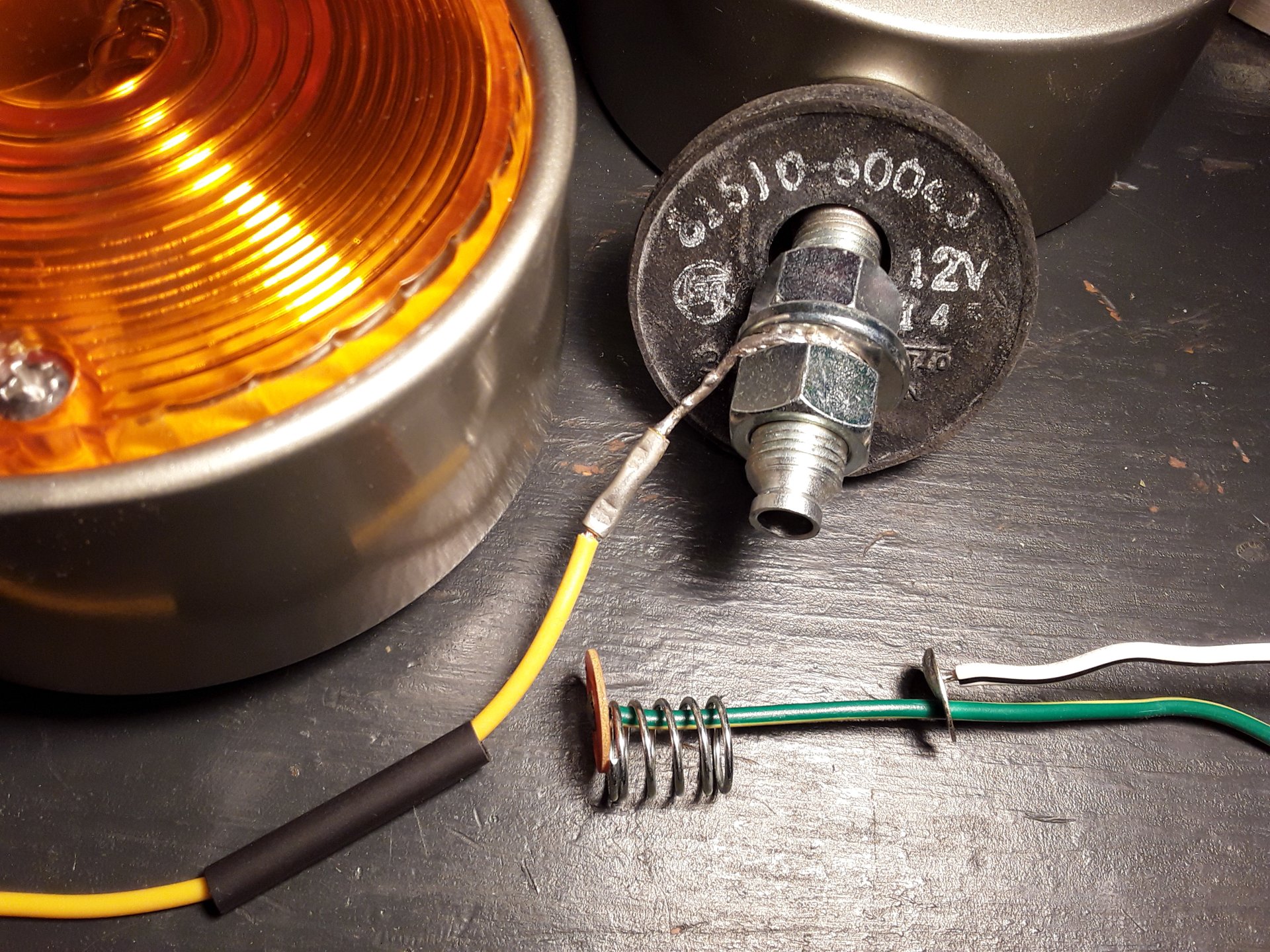

I'm working on a couple of things. First is making this a two-filament lamp. I'll get into that later.

Second is establishing an earth wire connection that doesn't need the hot green/yellow wire to pass thru it, like it came from the factory (white wire with black stripe is ground and lamp-socket spring seat).

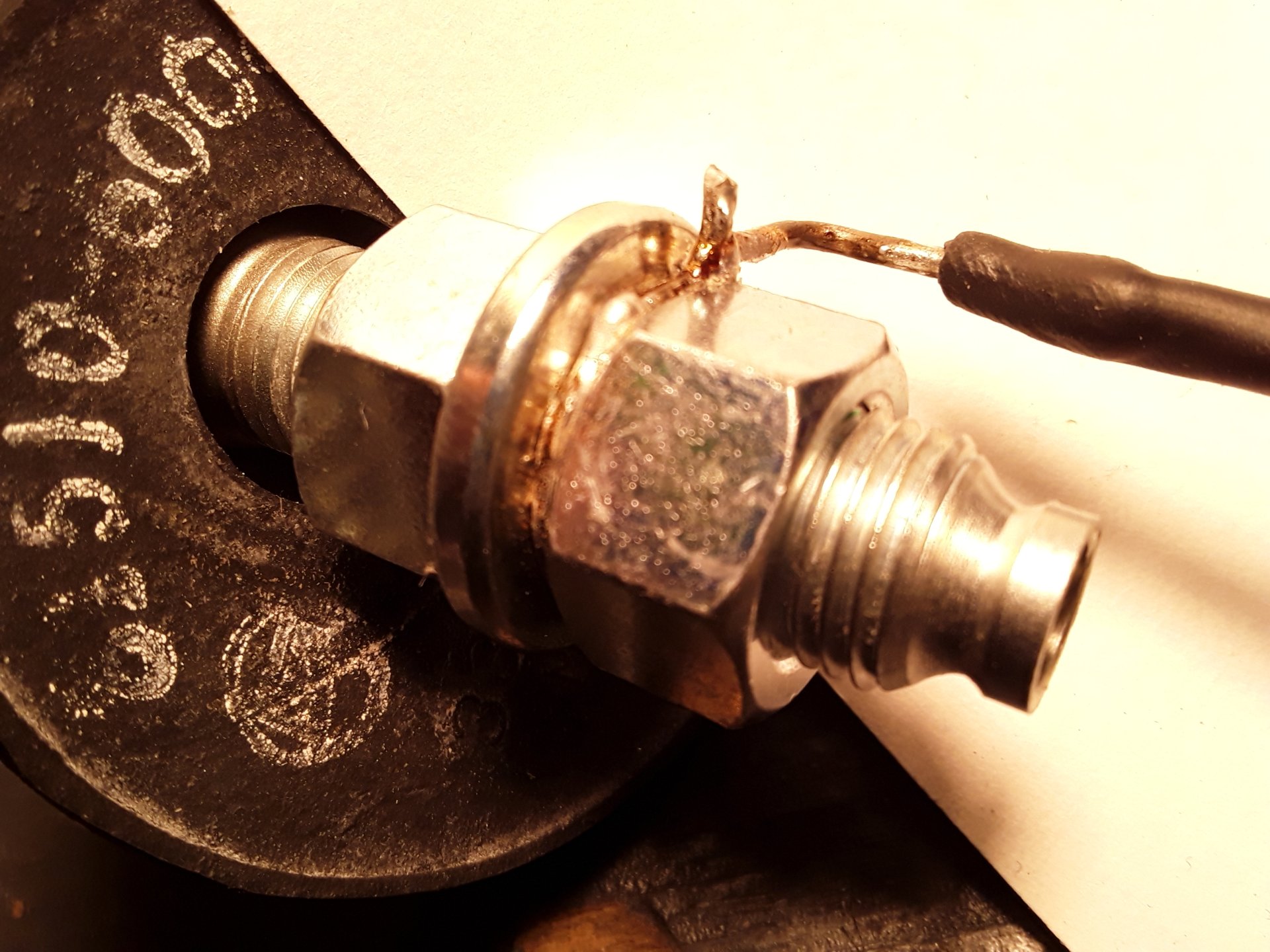

Also, I don't wan't to sandwich a copper with zinc plating loop terminal under that monster lock washer. It would probably work, but, it is not going to look pretty after you take it apart after torquing it down, and I've never seen copper used by the OEMs for grounding on a vehicle, all their rings/lugs on the frame and engine are brass, and they ideally employ a star washer.

I once heard of using lead as body filler. A piece of 'bailing wire' was cleaned and 'tinned' with electrical solder. Then it gets a unshielded solid crimp connector, which is crimped, then soldered. The M12 nut will make the ground connection to the chassis of the lamp, and the lead coated soft steel wire should minimize corrosion at the location of thread/fastener. (I once had a plumber use a section of steel pipe for gas on an outdoor spigot, the galvanic reaction from dissimilar metals caused the valve to fail within six months, and the water was really discolored.) Hopefully the braided copper grounding wire and its connector stays dry with some shrink tube under the fender.

I'm not sure that this is really a trail going anywhere, yet...

I'm working on a couple of things. First is making this a two-filament lamp. I'll get into that later.

Second is establishing an earth wire connection that doesn't need the hot green/yellow wire to pass thru it, like it came from the factory (white wire with black stripe is ground and lamp-socket spring seat).

Also, I don't wan't to sandwich a copper with zinc plating loop terminal under that monster lock washer. It would probably work, but, it is not going to look pretty after you take it apart after torquing it down, and I've never seen copper used by the OEMs for grounding on a vehicle, all their rings/lugs on the frame and engine are brass, and they ideally employ a star washer.

I once heard of using lead as body filler. A piece of 'bailing wire' was cleaned and 'tinned' with electrical solder. Then it gets a unshielded solid crimp connector, which is crimped, then soldered. The M12 nut will make the ground connection to the chassis of the lamp, and the lead coated soft steel wire should minimize corrosion at the location of thread/fastener. (I once had a plumber use a section of steel pipe for gas on an outdoor spigot, the galvanic reaction from dissimilar metals caused the valve to fail within six months, and the water was really discolored.) Hopefully the braided copper grounding wire and its connector stays dry with some shrink tube under the fender.

I'm not sure that this is really a trail going anywhere, yet...

Last edited:

Replaced all my break cylinders on my 64 fj40 because 3 had started to leak. Then broke a break line installing the last two cylinders. How it goes some times. I am glad I dug into the breaks though. A couple of the drums and pads were incorrectly installed. I'll rebuild the old ones for back ups when i run out of projects to do.

The good news is all the pads and springs seemed new! I think at some point the breaks were all done with new parts then maybe the car sat for a long time.

The picture below is the passenger rear break drum. I could not get the drum off without unbolting the cylinders. This is how they came off. pretty sure the springs are incorrect. it was not adjusted correctly. I think I have been driving around with this drum breaking all the time. The driver side drum adjusters were both facing up....

The good news is all the pads and springs seemed new! I think at some point the breaks were all done with new parts then maybe the car sat for a long time.

The picture below is the passenger rear break drum. I could not get the drum off without unbolting the cylinders. This is how they came off. pretty sure the springs are incorrect. it was not adjusted correctly. I think I have been driving around with this drum breaking all the time. The driver side drum adjusters were both facing up....

Last edited:

1911

chupacabra

Working on the bench due to season.

View attachment 3179376

I'm working on a couple of things. First is making this a two-filament lamp. I'll get into that later.

Second is establishing an earth wire connection that doesn't need the hot green/yellow wire to pass thru it, like it came from the factory (white wire with black stripe is ground and lamp-socket spring seat).

Also, I don't wan't to sandwich a copper with zinc plating loop terminal under that monster lock washer. It would probably work, but, it is not going to look pretty after you take it apart after torquing it down, and I've never seen copper used by the OEMs for grounding on a vehicle, all their rings/lugs on the frame and engine are brass, and they ideally employ a star washer.

I once heard of using lead as body filler. A piece of 'bailing wire' was cleaned and 'tinned' with electrical solder. Then it gets a unshielded solid crimp connector, which is crimped, then soldered. The M14 nut will make the ground connection to the chassis of the lamp, and the lead coated soft steel wire should minimize corrosion at the location of thread/fastener. (I once had a plumber use a section of steel pipe for gas on an outdoor spigot, the galvanic reaction from dissimilar metals caused the valve to fail within six months, and the water was really discolored.) Hopefully the braided copper grounding wire and its connector stays dry with some shrink tube under the fender.

I'm not sure that this is really a trail going anywhere, yet...

A color photo! What is the world coming to?

Last edited:

Mtntopper

SILVER Star

Lost the only key to original Ignition Switch. Thanks to @ToyotaMatt for having the proper OEM replacement available at a very easy to swallow price, we are now back on the road.

Lost the only key to original Ignition Switch. Thanks to @ToyotaMatt for having the proper OEM replacement available at a very easy to swallow price, we are now back on the road.

View attachment 3179509

View attachment 3179508

your Son looks like he is into what all he he doing there , and that's good ,

a Teq Mind is a terrible thing to waist ....

'

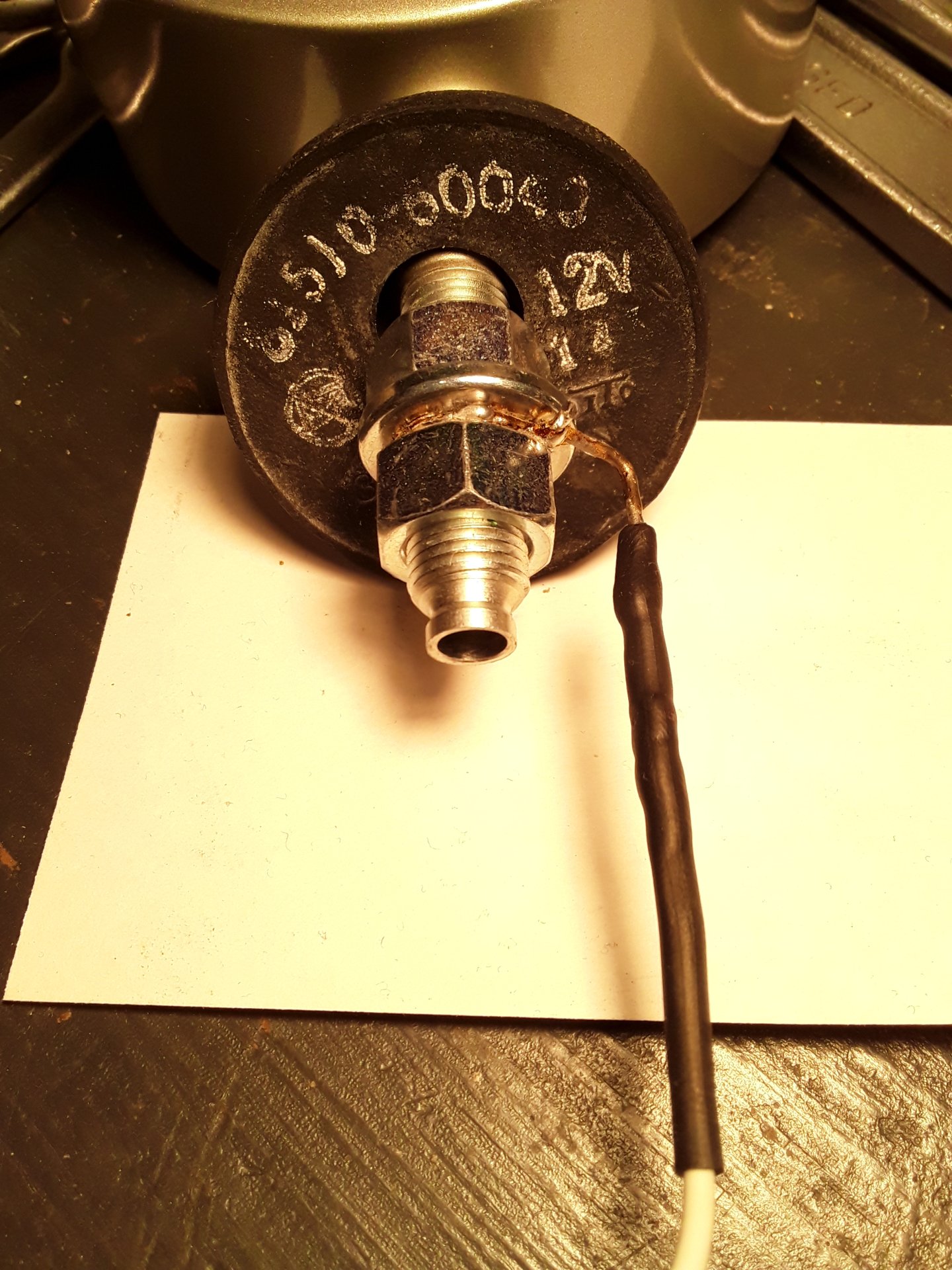

Attempt #2. This one was done on a proper mandrel (1/2" drill shank). The black is rosin, I hope. I folded the wire back after it made one full loop, then the two tags were soldered together so it is a complete ring. Really non-invasive way to do this on the later lamps ('75+).

Maybe a nylock nut is better, but, why change what already works (the front bumper is a totally different nylock-question)?

Maybe a nylock nut is better, but, why change what already works (the front bumper is a totally different nylock-question)?

Spent the afternoon racking up some miles on the 40 with the wife and new dog, while ending the day with a little ice house and microbrewery hopping in Houston!

Last edited:

suzuguru

SILVER Star

man, I love those yellow 40’s.

Similar threads

- Replies

- 306

- Views

- 30K

Users who are viewing this thread

Total: 36 (members: 17, guests: 19)