Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mike's 1978 FJ40 Build (7 Viewers)

- Thread starter 78fj40mg

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?If you can't wait, tap an old screwdriver counterclockwise against the nut - if the lock ring has been straightened so it's not keeping the nut from moving, should loosen easily and you can unscrew it, pull off the lock ring and unscrew the inner locknut.

78fj40mg

TLCA #23510

- Thread starter

- #303

Could not wait for the socket to arrive so I lightly tapped it and the nut came off, I will still need the socket for the passenger side and also to reinstall the nuts.

Removed the inner nut and bearing

and removed the disc brake

next I unbolted the steering arm to loosen the upper pin

then removed the spindle

Removed the inner nut and bearing

and removed the disc brake

next I unbolted the steering arm to loosen the upper pin

then removed the spindle

Last edited:

Great documentation Mike!!

1Fine40

Rust Buster

Your work is great! I've already been through much of what you are doing now, and it is such gunky fun! For that inner axle seal, try getting the ones from Marlin Crawler. The "eco-seal" is superb, and I have had zero leaks from it in 5 + years of use/abuse. FWIW, I really like Them

Keep up the great work and especially the pix!

Cheers!

Keep up the great work and especially the pix!

Cheers!

How come you haven't installed this stuff yet, Mike?

78fj40mg

TLCA #23510

- Thread starter

- #312

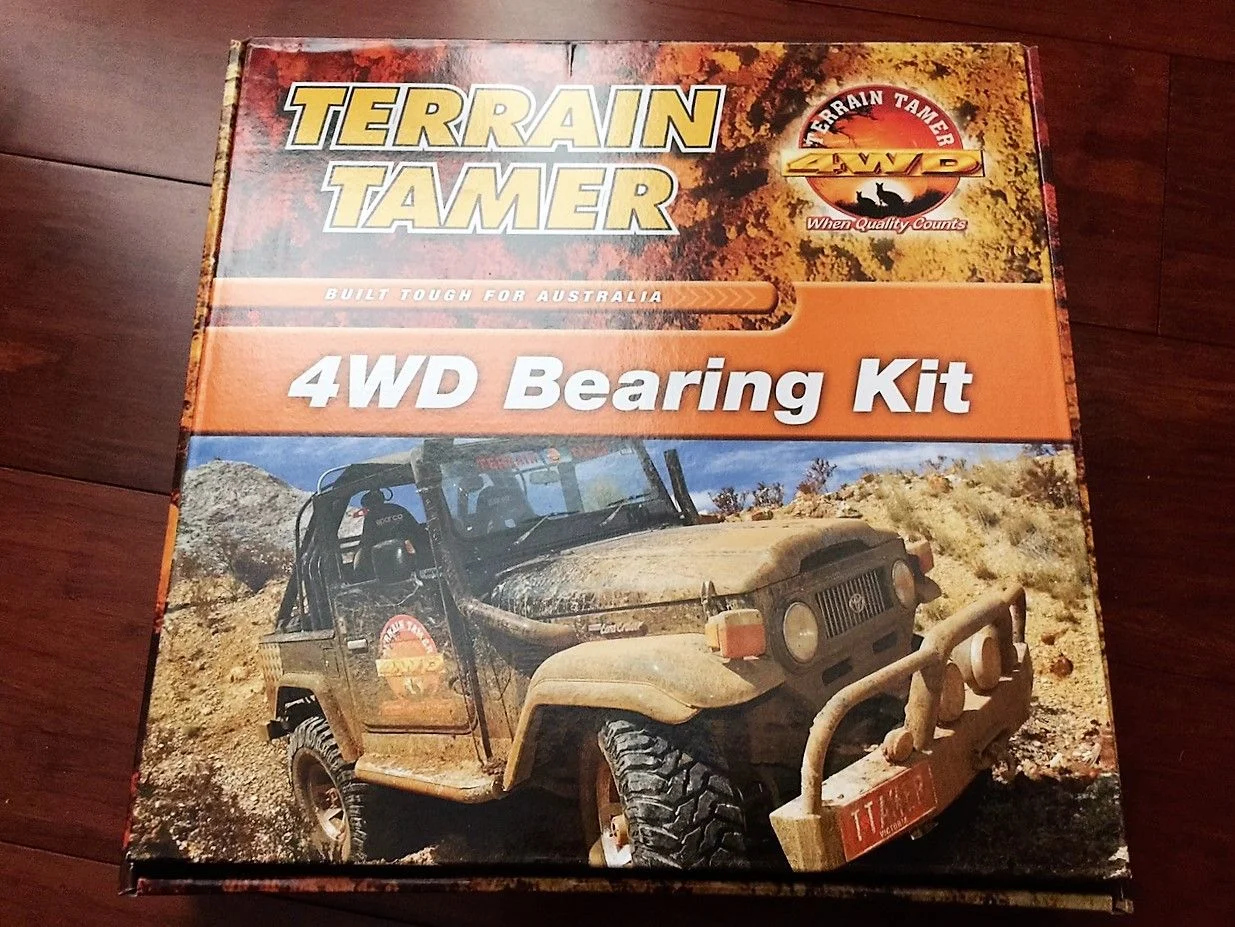

I've been doing research on steering knuckle centering tools including the Toyota SST which is expensive and hard to come by. I found another centering tool solution that appears to be easy enough to make and should be relatively inexpensive. Courtesy of Pirate4x4.Com

Here's the tool

Specs for tool can be made out of any material

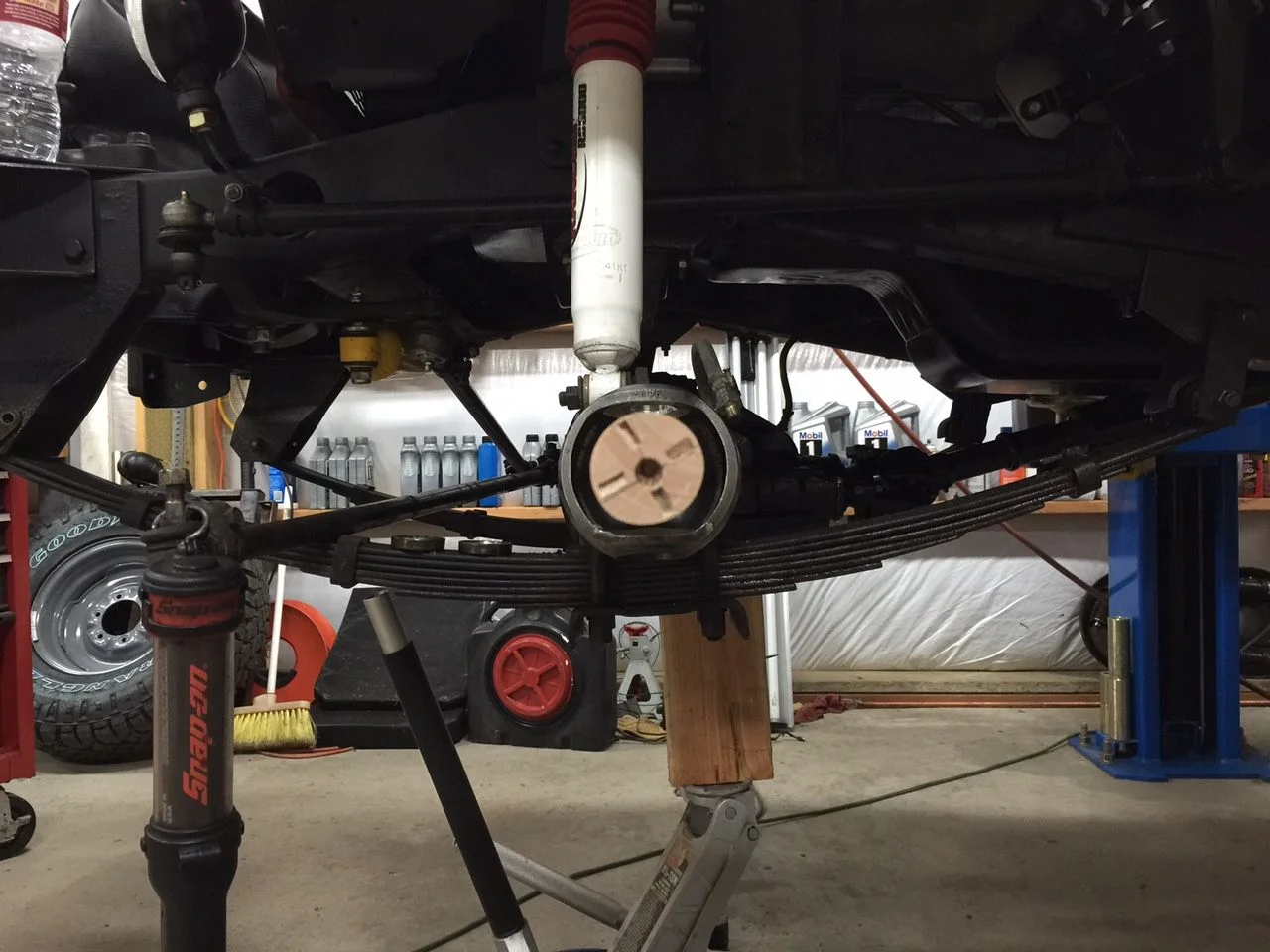

This is how the bushing fits in the axle housing with a dummy shaft to center the knuckle

Once the knuckle has been centered after you've added the appropriate number of shims to obtain the desired 13Lbs preload then install the real axle and you are done.

Installation and centering procedure here Pirate4x4.Com

Here's the tool

Specs for tool can be made out of any material

This is how the bushing fits in the axle housing with a dummy shaft to center the knuckle

Once the knuckle has been centered after you've added the appropriate number of shims to obtain the desired 13Lbs preload then install the real axle and you are done.

Installation and centering procedure here Pirate4x4.Com

Last edited:

Mike, great work! THANK YOU for taking the time to document this. Your efforts will help many tackle a job like this that they otherwise might not have. Not to mention, just adding to the mud knowledge base! Also, I like how you make sure to put the tool that was used for a particular step in the picture.

fj401978

Skip

You're an awesome documenter! Thanks for all the details, Mike...sure going to come in handy!!

DSB345

SILVER Star

Great detail and Info on tools etc.

78fj40mg

TLCA #23510

- Thread starter

- #318

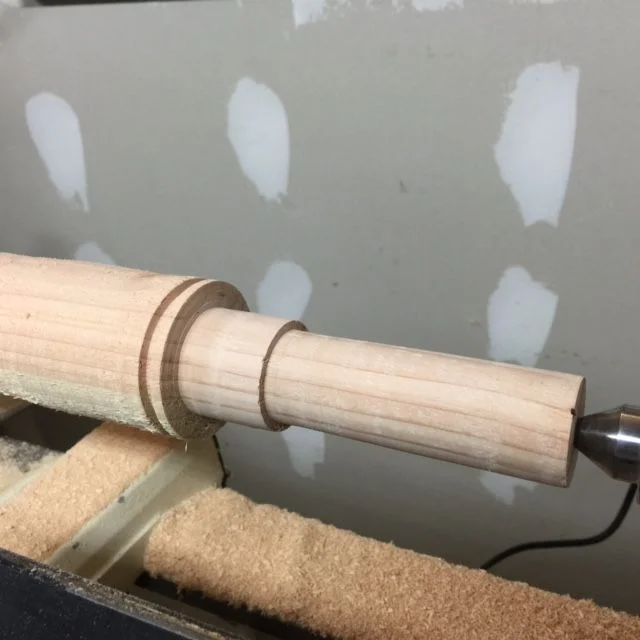

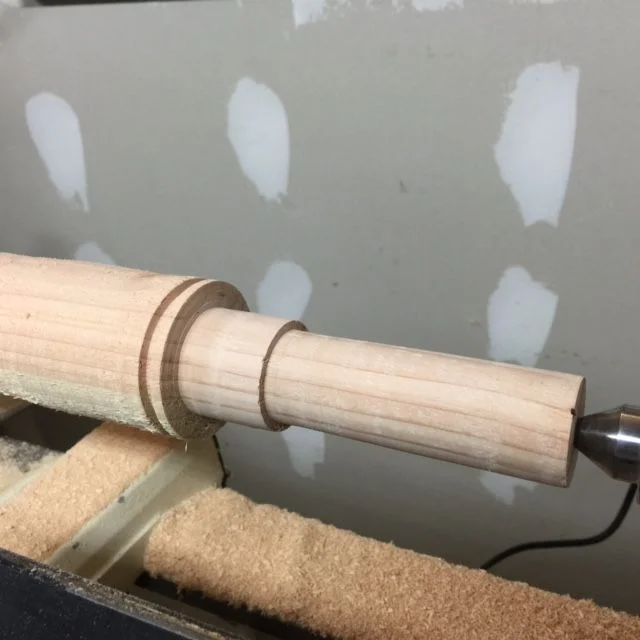

Here's my attempt to make a centering tool:

I decided to attempt to make one of these centering tools made out of wood. I'm not sure of all the dynamics of this as yet and how it will actually work or not work, but I wanted to run this by y'all for some constructive comments, suggestions and improvements or to just trash it, what ever you guys think. So here's what I did:

The original idea from Pirate4x4.Com was this:

Here's my wood contraption on sketch form as a single solid shaft and bushing combined following all the dimensions as indicated

I started with a piece of stock wood

I turned the dowel and bushing combo with very tight tolerances

It fit like a glove, (very tight glove), in the shaft housing I'm happy with how it turned out but the question is will it work?

I decided to attempt to make one of these centering tools made out of wood. I'm not sure of all the dynamics of this as yet and how it will actually work or not work, but I wanted to run this by y'all for some constructive comments, suggestions and improvements or to just trash it, what ever you guys think. So here's what I did:

The original idea from Pirate4x4.Com was this:

Here's my wood contraption on sketch form as a single solid shaft and bushing combined following all the dimensions as indicated

I started with a piece of stock wood

I turned the dowel and bushing combo with very tight tolerances

It fit like a glove, (very tight glove), in the shaft housing I'm happy with how it turned out but the question is will it work?

Last edited:

You are very creative Mike!! Nice Jet tools too!!

I'm not mechanically gifted, but I think, if your tolerances are tight, it will probably work well... For a limited number of iterations, being its wood.

But, for the number of times you are likely to use it, use it carefully and it will probably serve you well.

Of course, given I know very little about the science behind the knuckles tolerances... I could be wrong...

I'm not mechanically gifted, but I think, if your tolerances are tight, it will probably work well... For a limited number of iterations, being its wood.

But, for the number of times you are likely to use it, use it carefully and it will probably serve you well.

Of course, given I know very little about the science behind the knuckles tolerances... I could be wrong...

DSB345

SILVER Star

Very creative!

Similar threads

Users who are viewing this thread

Total: 8 (members: 0, guests: 8)

seal that was leaking oil in the knuckles

seal that was leaking oil in the knuckles