So I'm finalizing my L8T engine location in my FJ80 frame, but I don't have a body for reference

My reference points are the rear of the original 1FZ head. And centerline of the engine. Goal being to keep the engine as low and rearward as possible.

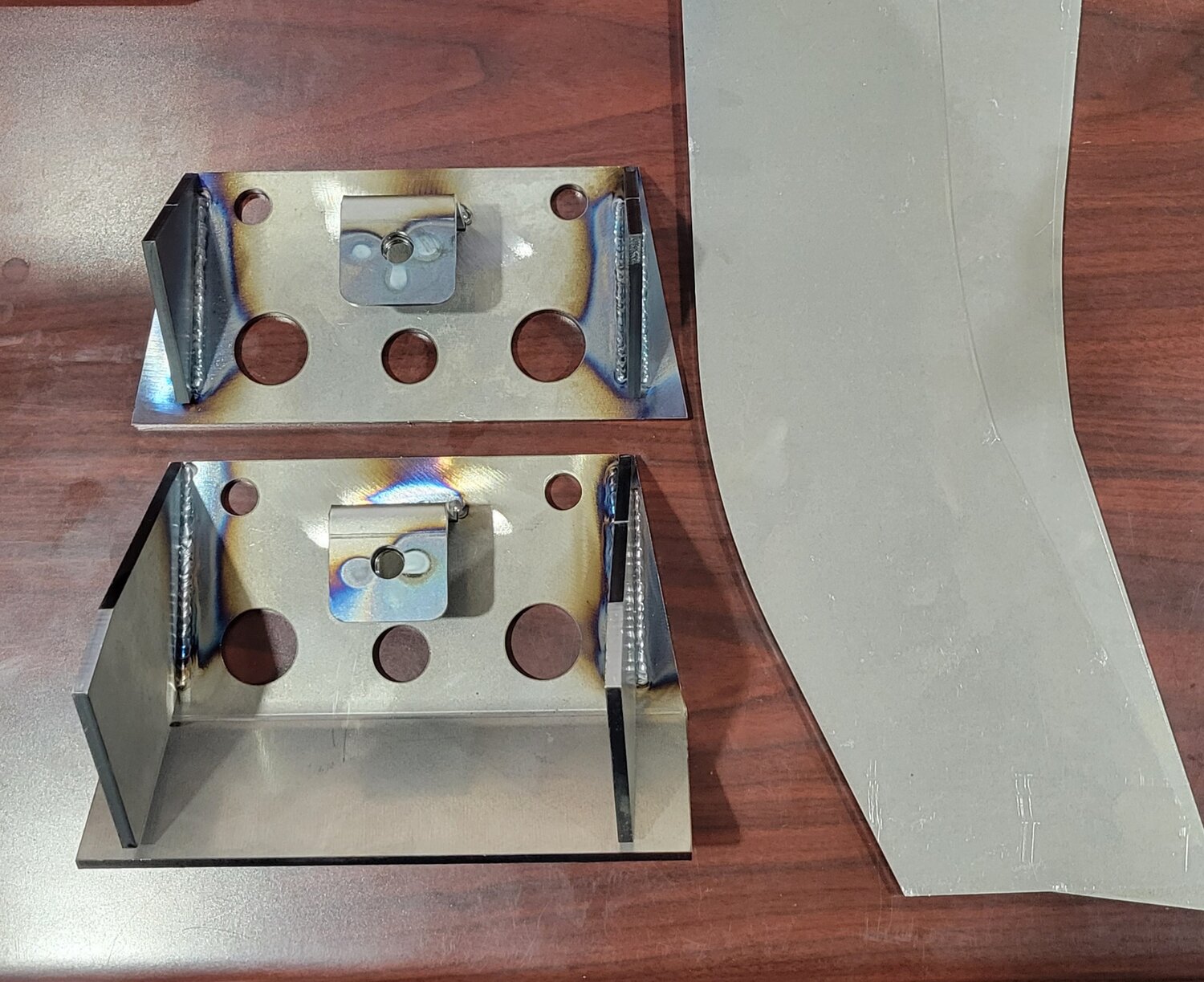

I'm utilizing the original trans crossmember and the lower portion of the mount. After mounting an oem chevy mount, and 1" tube to help offset the bolts to the rear, I still needed some vertical offset, and the original FJ80 mount fit tge bill. Factory crossmember and the chevy mount result in a 1"offset to the drivers side.

Troublespot is the left exhaust flange. I'm having to raise the front of the engine more than I had hoped, but don't really want to scallop into my frame rail to gain the clearance.

I've looked through a few pages of this thread, but haven't seen exactly what I'm looking for. I just wonder what others think of this engine position and mounting. Keep in mind tge L8T is just over 400hp.

There will be some boxing and gussets of those mounts. And the front of the engine is centered. So the engine is not quite parallel to the frame, providing it is symmetrical.