I've fallen deep down the rabbit hole and decided to build my own drawer system-despite having zero wood working/carpentry experience. My initial plan was to wait for

Dave, but he's a very busy man and there isn't currently a timeline for 200-specific KISS drawers.

Step 0: Research

I'm a product designer in my professional life, so I approached this like any other problem and started by trying to educate myself.

These three resources really helped me:

Aside: Deconstructing Dave's KISS drawers

made me really appreciate the amount of care he put into designing them. So many little details in his design.

Step 1: Constraints

First, I need to understand the footprint I had to work with. I took some measurements and scaled a trunk mat to get the approximate layout. The only critical measurement is the 41.5" between the wheel wells. I decided to make my drawers 40" long to leave plenty of room for the power second row (my kids constantly fidget with it).

Next is to establish drawer height. My wife and I are short (I'm 5'6") so anything too tall would mean we couldn't reach our ARB 50L fridge. We got a good bit of perspective checking out the

Adventure Ready 80 series. It has a ~3" lift and ARB drawers (which are about 12" high):

Even with the drop slide (which is crazy expensive!), the fridge was a touch reach for us. So I went home and started making some physical mockups. I wanted to visualize a 10" drawer height—this tub was closest thing I had (~11" high):

The killer AHC feature is comfort access, which drops the rig to her bump stops on exit. This will be very helpful for two shorties like us. If my calculations are correct, the fridge opening should be between 26-28" off the tailgate on level ground. We can work with that.

Next, I had to convince my wife that our s*** would fit into 2 drawers. More physical mockups:

We still have tents and bags and chairs, but those will go on the roof. Success.

Version 1: Copy what Dave did

I didn't get very far here

I got a mostly complete list of 8020 parts my shopping cart was nearing $300. Not including birch and hardware. I aborted. Plus, as a product designer, it felt wrong to try to copy Dave. Maybe that's just my hangup.

Version 2: Just a box

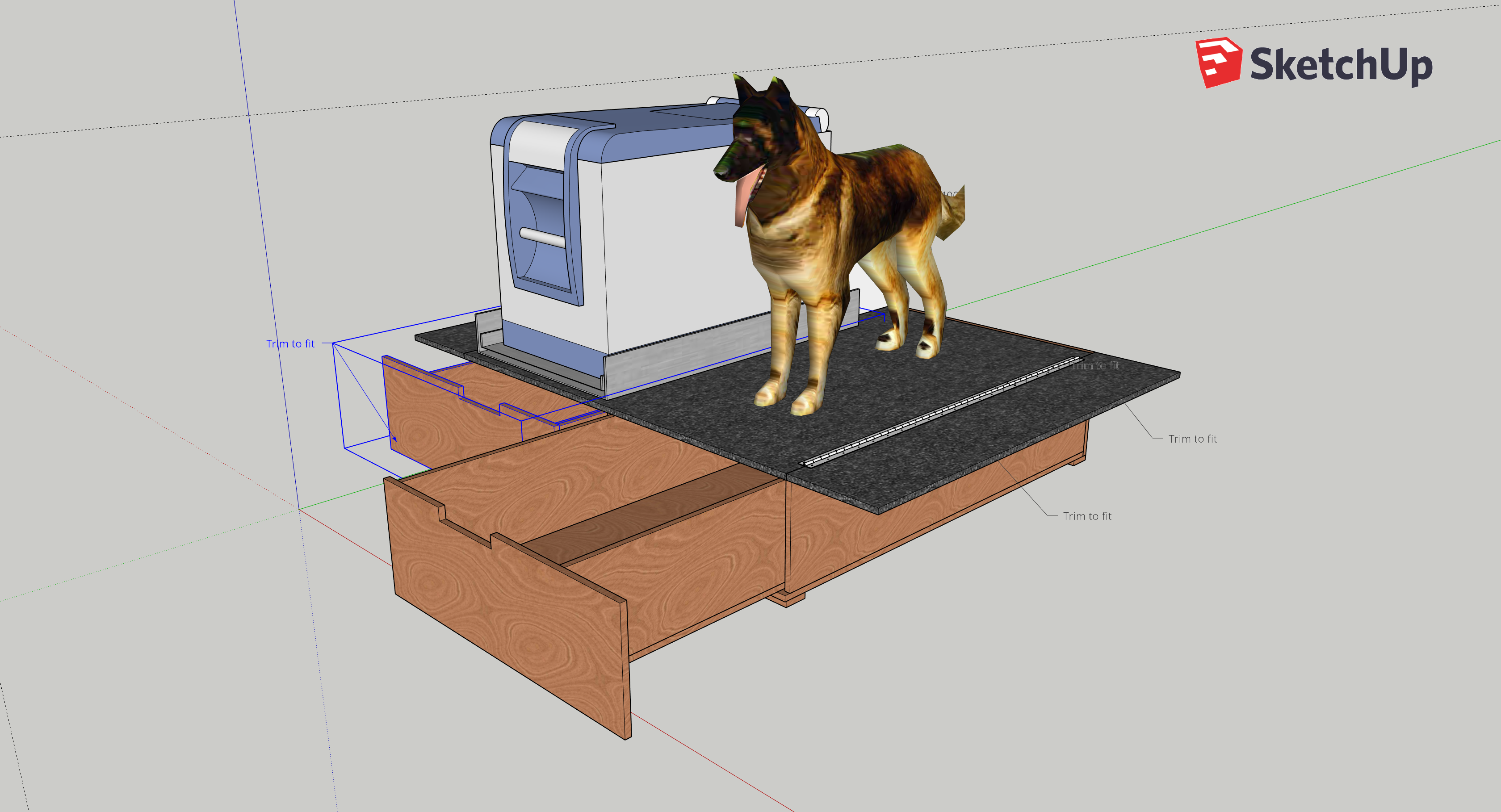

This time around, I was determined to learn Sketchup to help my visualize my plans. My initial though was to not do wings and just build a big ass box with HPDE "runners" under each drawer instead of slides:

This version was really just practice-I made a bunch of mistakes here including making my drawers the same size as the opening. No bueno.

Version 2

I decided that I really want the wings. I plan on storing my tool bag and compressor outside of the drawer, so having them covered is desirable. I also found a model of my fridge—really helped me visualize scale

Triangular "brackets" would support the wings:

Version 3:

After looking at plywood, I decided that I wanted to use 3/4" for the top instead of 1/2". I also hacked up cardboard to make a template for my wings:

Not sure what I'll do about the inverter yet...Having this mocked up was helpful because it showed me how much space my "brackets" would eat up in the void between the wheel wells and the drawers. This time around I decided that a 1"x1" stock could support the wings. I also figured out the radius of the hatch opening and incorporated them into my design:

I'm still undecided how I'll finish the drawers—stain, carpet, rubber, paint, etc. First step will be to get box built over next few weekends.

Stay tuned, and wish me luck!