I can finally say that the gauge install is COMPLETELY finished.

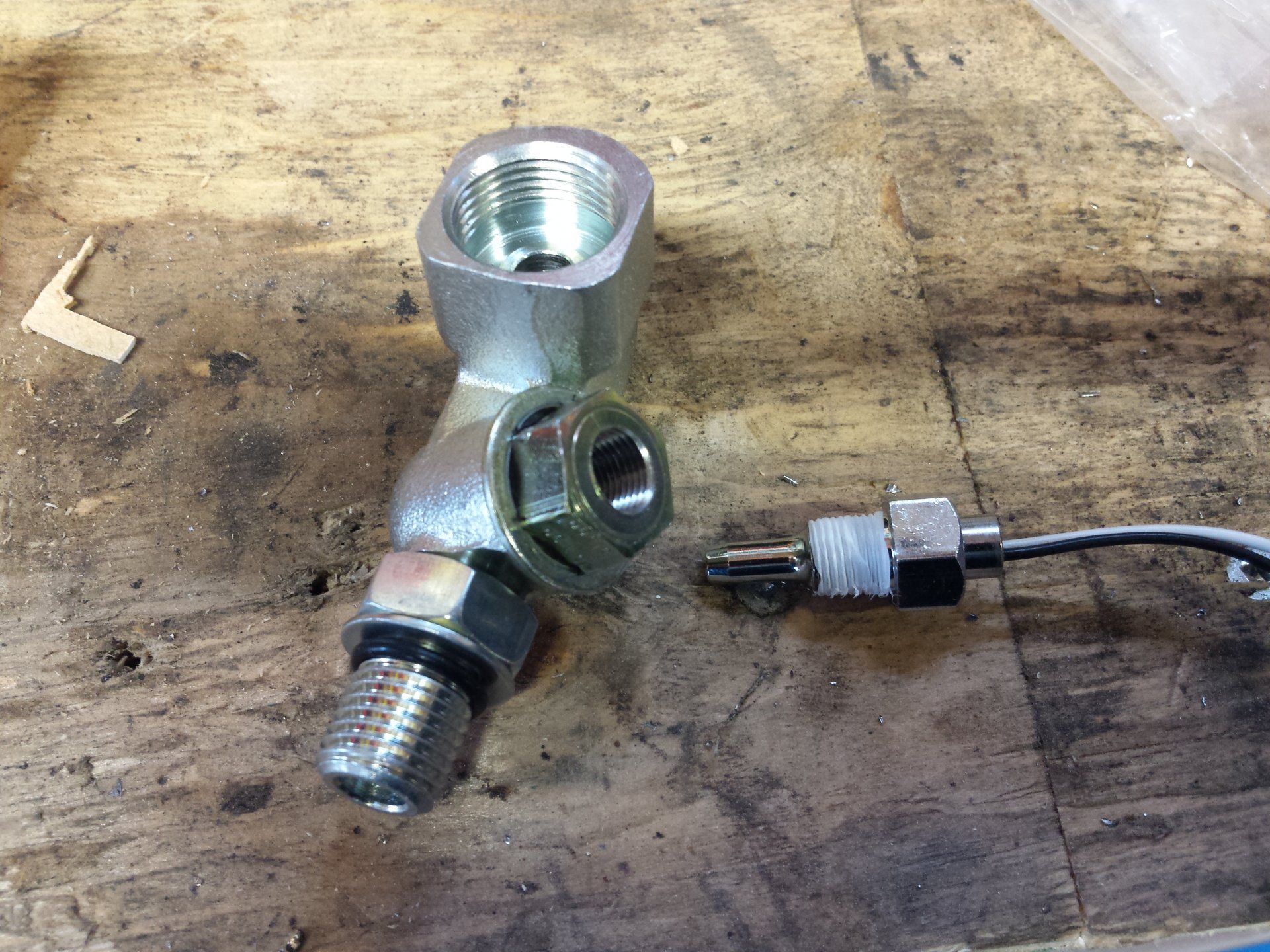

Got the tranny union in the mail from

@IanB. Started looking at drilling it so I could keep both parts, but the sender that was provided is pretty long, not the flush button type that the factory one is. Looking at the 90 degree bend in the union, the hole gets REALLY small in there, so I didn't want to impede the flow any more than it already was. Ended up grabbing a M16x1.5 plug, and drilling that out to replace the factory temperature switch. It seems to fit pretty much perfectly, with the end of the sensor just entering the fluidspace in the union.

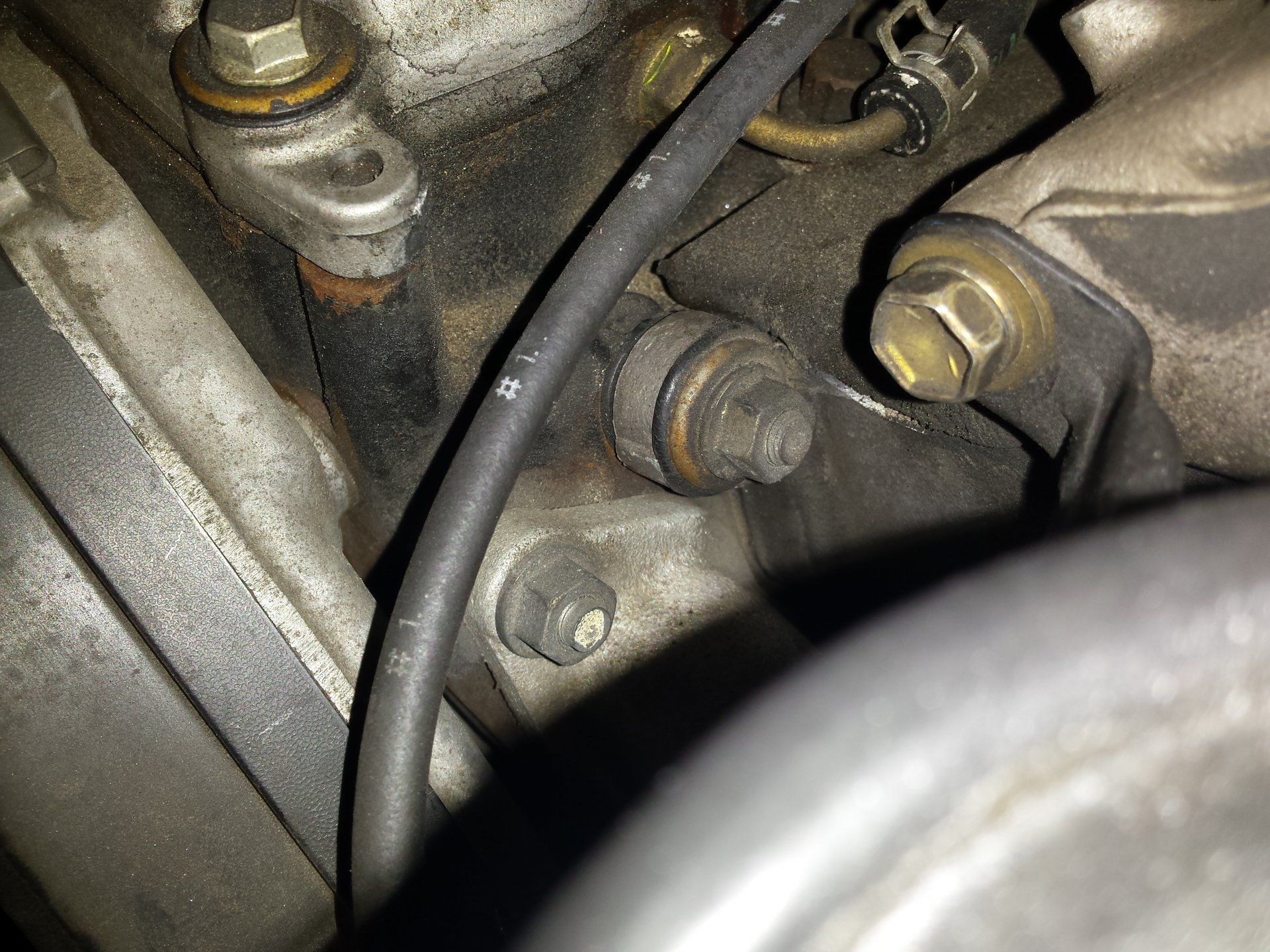

Installation was a BITCH, to put it simply. Looking up there, I figured that union is in a pretty accessible location, and shouldn't be a problem. Actually trying to do it was a different story. The JIC/Compression (I don't know which it is) fitting on the hardline going to the rad was CRAZY tight, and in a spot where a wrench can only turn about 5 degrees before hitting everything else in the area. Spray the whole thing with PB, smack it with a hammer, and grunt like hell. Then, once its loose, the hardline is so difficult to move out of the way because of the awkward position. Once that's figured out, you can't turn the union out of the tranny because of that wierd useless looking mounting bung beside it, so you have to take the factory sendor out first. And do it all in an area that's been having grease from the driveshaft slung all over it for the last 20 years. Then reverse of everything to put it back in there. Wasn't much fun.

Routed the cable from inside the engine compartment down the shock tower to the frame, and followed the frame over.

The factory sensor must be N/O, because I'm not showing the error light at all, and I figure having the temperature right there should be a bit more informative than the error light anyway. And, it's a Japan vehicle, so no OBD to worry about throwing a code by removing it. So, I just tye wrapped the plug there and will leave it alone.

First couple drives around town show me I'm running around 150-155F when it's up to temperature, which seems reasonable, haven't had it on the highway or in any hills yet.

Oh yeah, and just now, a month after I got the thing, I got a bill in the mail from Fedex for $60 for customs. So, my total bill was closer to $290 for the thing. Not the end of the world, but still a piss off.