Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I finally get the shop I have wanted for too long (6 Viewers)

- Thread starter Michael B

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?@Michael B looks TERRIFIC!….Congratulations on having the shop you have always wanted…. I feel the same way 1800 miles away. The stone is so sharp looking and adds a layer of style well above a work building. So my wrap-up question is….. did the cap stone get laid flat against the corrugated shape of the steel or get shaped accordingly?

Last edited:

Michael B

SILVER Star

- Thread starter

- #364

Thank you! I’m very pleased with the end result. He did notch the cap stone. I will get you a picture of that this afternoon.@Michael B looks TERRIFIC!….Congratulations on having the shop you have always wanted…. I feel the same way 1800 miles away. The stone is so sharp looking and adds a layer of style well above a work building. So my wrap-up question is….. did the cap stone get laid flat against the corrugated shape of the steel or get shaped accordingly?

that must have been a laborious job…but a classy final for the finish. My wife had an oval bronze looking plaque made for above the entry door for me. 40 years ago we took a bunch of letters from all of our first names to tried and spell a name for the farm….she had that name and it reads ‘ established June 2022” when the building got started going up. Looks cool . Similar to those roadside historical markers. I’ll send you a photo of it later

Oh boy that looks great. Thank you for sending this…. They are obviously pros cutting these stone caps… if I do this…. I’m am happy that the 9 foot wide door trims the total length to a bit over 17’ only. I will be a few days away from starting this

Michael B

SILVER Star

- Thread starter

- #368

You’re welcome. I look forward to seeing your progress!Oh boy that looks great. Thank you for sending this…. They are obviously pros cutting these stone caps… if I do this…. I’m am happy that the 9 foot wide door trims the total length to a bit over 17’ only. I will be a few days away from starting this

Michael B

SILVER Star

- Thread starter

- #369

The stone mason recommended that a sealer be applied after about a week. We discussed different brands and I think I have decided which one I will use. So I decided to rinse the stone off since it was dirty when it arrived and there was dust from cutting the top cap on a portion of one wall. Wow! What a difference a fresh water rinse made!! The stone colors are very visible. It looks like a completely different wall. In these pictures the stone is still wet. But even when it dries there is a huge difference.

Have to agree, the wet appearance sure makes the colors pop? Either way it looks great!

I have to also agree… I have been closely examining your photos (no not stalking) as I just love the way this came out. I have a very bland wall end that is the first visible impression when you drive up. This addition to the side will add a significant change to the view

the stone has color and makes a vivid presentation

the stone has color and makes a vivid presentation

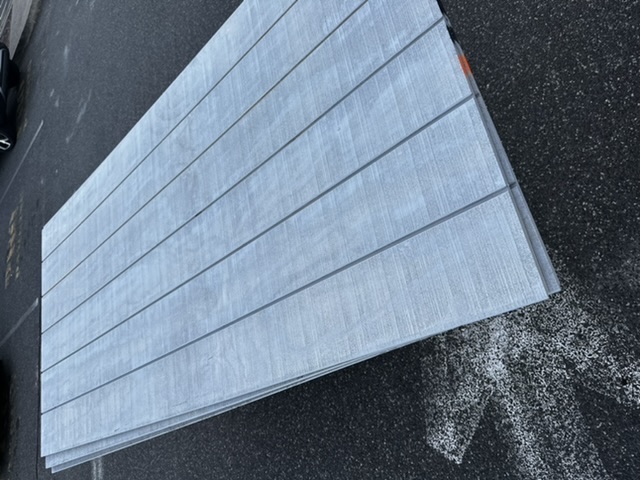

@Michael B any reason the stud are closer than 16” on center? i am doing something to cover the foam spray using these T-111 horizontally and peg board in some areas above

Michael B

SILVER Star

- Thread starter

- #375

I went with 12” OC because of the mezzanine I’m building overhead. There will be no failure due to supporting structure.@Michael B any reason the stud are closer than 16” on center? i am doing something to cover the foam spray using these T-111 horizontally and peg board in some areas aboveView attachment 3122561

Michael B

SILVER Star

- Thread starter

- #376

I had a rather productive weekend in the shop. If I had some 2”x12” material on hand I could have stood the second wall up. BTW I bought 1-2”x6”x20’ for this section of the project. Everything else was either leftover from the initial shop build or salvaged materials. There are 24-2”x6” studs in the two walls. Plus the jack and cripple studs. I’m also at the end of the 25 lbs bucket of 3” screws that I bought in January.

Michael B

SILVER Star

- Thread starter

- #377

Today went rather well. Terrific weather! Last night it went down to 42 here and the shop was 65 when I went out there about 8:00 this morning.

I had a productive day. First I applied a sealer to the stone. Then I installed the headers and top plate. It took about 2 hours to stand the wall up and move it into place.

I had a productive day. First I applied a sealer to the stone. Then I installed the headers and top plate. It took about 2 hours to stand the wall up and move it into place.

Not a one man job for sure…. Funny part is, of all the people who sad..”if you need help, let me know”. I wound up doing all my stuff myself

EWheeler

GOLD Star

Love watching this come together. The stone really did set off the look on the outside, great work. Thanks for bringing us along for the ride.

Similar threads

- Replies

- 139

- Views

- 13K