1911

chupacabra

- Thread starter

- #181

I'd reckon there's more progress going on over there! Good to catch up on the project. Very cool. How are you planning to finish the ceilings? Leaving them bare concrete or framing out more traditional hard lids with drywall? I'd assume the main rooms are open vaults, but what about bedrooms and hallways?

Thanks!

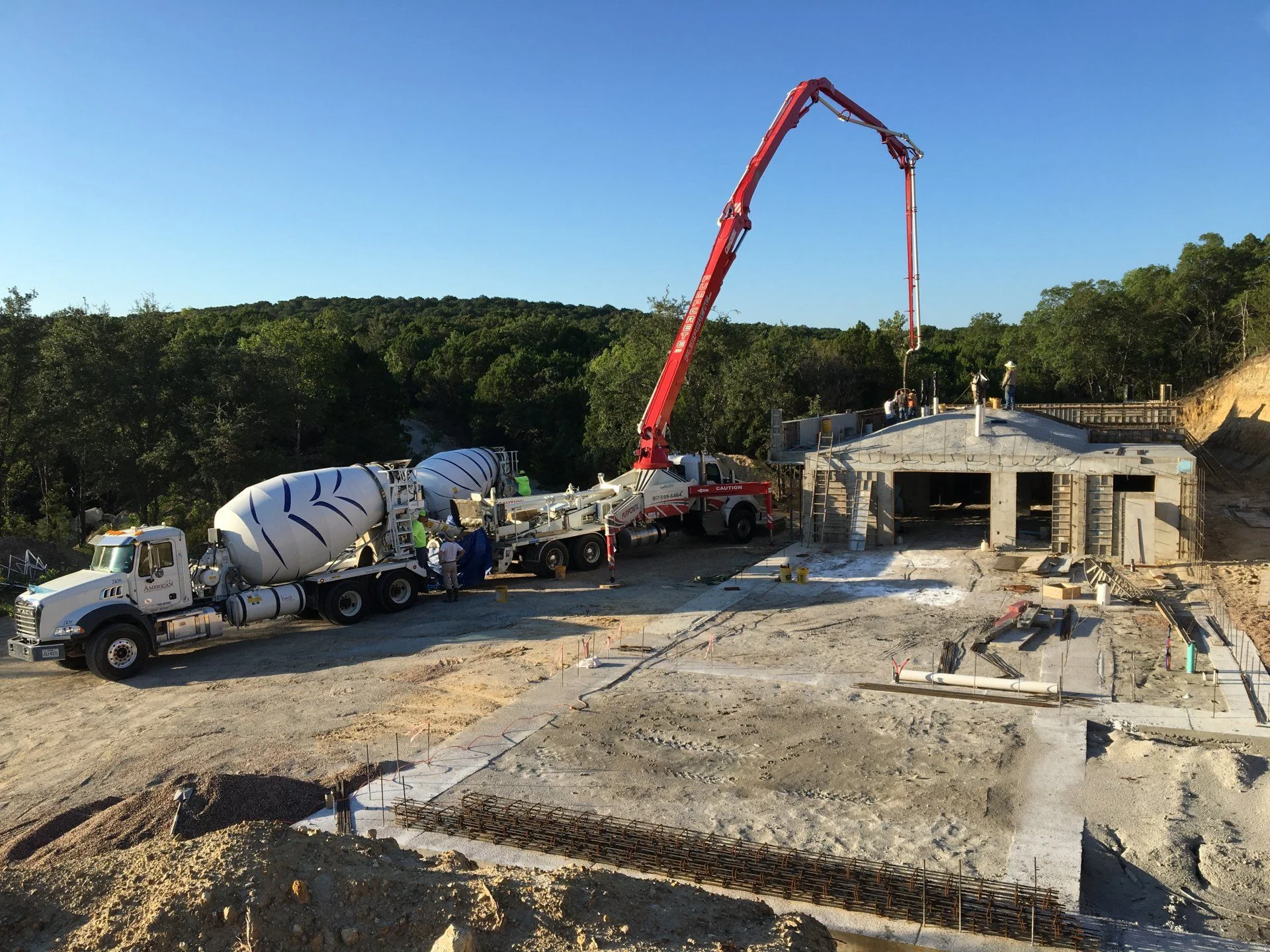

Nothing more has happened since my last post; the builders are off on vacation for 2-1/2 weeks, as one of the partners is getting married. Just before that, there was a mix-up in the scheduling of the concrete pump truck, so the second module did not get poured yet. It is supposed to happen on August the 11th now.

The ceilings (and exposed concrete walls) will be plastered over with a synthetic (epoxy) stucco product. The larger rooms (kitchen, living area, etc.) will be open as you surmise. The more you can leave the domes open, the more light will reflect and the better air will circulate. But there will be some interior walls for bathrooms, the guest suite, the home gym, a hallway, and etc. Those will be conventional framed walls, but we have the option of making them only eight feet tall, and no ceilings, so that you get light reflection and air circulation in all rooms. Mrs. 1911 is not inclined that way however, so many of the interior walls will go all the way to the dome ceiling for sound insulation purposes if nothing else. We'll see when we get there - there is still a lot of flexibility in the interior room design.