Not how far along you are, but pull the motor out carefully with the intention of re-using everything. That way you can if you need to. You won’t really need any engin wiring, you’ll need the transfer case wiring which is connect to it.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Registry 8x Series V8 Swaps (16 Viewers)

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?So you’ll need to say where you’re at. I don’t want to go over it all if it’s a ways out for you. I just did one project at a time. Got the gm motor and trams ready, rebuilt them, then I pulled the motor out. Then you can start to thin out the Toyota harness and start to gain familiarity with it and all. Download the factory service manual. Print out the Toyota, power, engine control, transmission, and combination meter “dash” wiring diagrams. And tape the pages together. Print out the pages that show the pictures and pin outs for the engine firewall to Toyota Ecm connectors.

i have a p95 pcm with an 05 5.3 dbw that I'm keeping dbw. engine is out, trans and transfer case will come out this week so I can mate my 4l60e to my Toyota transfer case. my ls side of the wiring harness is done, this just reminded me to order coolant sensor from wits end. should have my passenger side mount cut and welded this weekend. maybe a weekend or two off from bolting engine in as I'm waiting for misc. parts like exhaust manifold bolts.So you’ll need to say where you’re at. I don’t want to go over it all if it’s a ways out for you. I just did one project at a time. Got the gm motor and trams ready, rebuilt them, then I pulled the motor out. Then you can start to thin out the Toyota harness and start to gain familiarity with it and all. Download the factory service manual. Print out the Toyota, power, engine control, transmission, and combination meter “dash” wiring diagrams. And tape the pages together. Print out the pages that show the pictures and pin outs for the engine firewall to Toyota Ecm connectors.

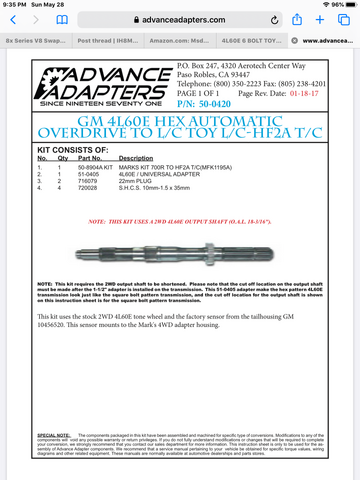

Each situation is different. But can you change the shaft?Hello everyone, can someone please help me with an answer? I’m working on an engine swap and I bought the adapter kit for LS to Toyota transfer case on my 92 80 series L.C. The first mechanic that was working my swap installed the 5.3 Vortec with a 4wd 4L60 e. It’s required hat I use a 2wd shaft. Can I just change the shaft to the longer 2wd without any other changes to th tranny. I do not want to have to but another transmission just for the longer shaft, if not needed?

Yes you probably can. It will require the trans to be torn down. I assume you are doing that? You will have to put it back together. I’m addition you will have to make sure components work. Parking Paw etc. I did all of this with a 6l90. Only to find out that the trans was crap anyway.

Why not use a 6l80?

Can anyone shed a little light on this. Working on extending the wires for the oil pressure sender. I see the noise filter that connects to the spade on the oil pressure switch and white wire to the round knob. Question is, did you use the noise filter still in your swap, and did you need a ground for the oil level switch Y-R wire or did it ground when low? Thanks!

View attachment 3278731

View attachment 3278732

Did you ever sort this out? I extended mine and can’t get it to read while priming my engine. Haven’t actually started it yet. Partly out of a fear of no oil pressure.

thatcabledude

GOLD Star

New or freshly rebuilt engine?Did you ever sort this out? I extended mine and can’t get it to read while priming my engine. Haven’t actually started it yet. Partly out of a fear of no oil pressure.

I haven’t gotten the gauge to work. The power comes through the indicator in the truck, so I think my is busted. I haven’t opened it up yet. I’d recommend just putting on a cheap mechanical at first to verify it. If you’re working on a vehicle you don’t know worked before. I didn’t prime my rebuild. A lot who do, a lot who don’t. When I reassembled it I used a ton of oil and lube. Before I tried to start it. I pulled the plugs and pulled the ignition fuse and cranked it alot. It spins very fast with not compression. After several cycles of cranking, I attempted a start. Oil pressure was immediate on a LS motor.

If you’re trying to prime it with a pressurized can, I’d do it before you install it. Once in, it’s kinda a pain to get to and a mess. Don’t over think, unless you built a 500 hp motor. Realize, GM doenst prime every motor off the line. They come from the engine house, get put in a car and an old lady hops in and fires it up, throws it in gear immediately and drives it off the line to park, no “break in oil” no warm up, no priming. Not like you buy a new car and say, oh I better put break in oil in this. Drive it 100 miles, change the oil and move on.

If you’re trying to prime it with a pressurized can, I’d do it before you install it. Once in, it’s kinda a pain to get to and a mess. Don’t over think, unless you built a 500 hp motor. Realize, GM doenst prime every motor off the line. They come from the engine house, get put in a car and an old lady hops in and fires it up, throws it in gear immediately and drives it off the line to park, no “break in oil” no warm up, no priming. Not like you buy a new car and say, oh I better put break in oil in this. Drive it 100 miles, change the oil and move on.

You are correct. Automakers do not prime new engines, there is no break in oil and the first time the engine starts is to drive it off the assembly line.

The thing is, a new engine on the assembly line is controlled to the micron. Your engine from Big Bubba's Engine Rebuild and Bait Shop is unlikely anywhere remotely close to the same precision.

I suggest assembly lube at a minimum and priming is good practice, but not required.

Proper ring break in is the most important. You need to run the living piss out of it. Don't take it easy on it or let it idle.

tmxmotorsports

SILVER Star

The last part made me laugh sounded like my auto mechanic teacher in high school he was an old timer when I was in high school best teacher i ever had.You are correct. Automakers do not prime new engines, there is no break in oil and the first time the engine starts is to drive it off the assembly line.

The thing is, a new engine on the assembly line is controlled to the micron. Your engine from Big Bubba's Engine Rebuild and Bait Shop is unlikely anywhere remotely close to the same precision.

I suggest assembly lube at a minimum and priming is good practice, but not required.

Proper ring break in is the most important. You need to run the living piss out of it. Don't take it easy on it or let it idle.

Fresh rebuild.New or freshly rebuilt engine?

If you’re trying to prime it with a pressurized can, I’d do it before you install it. Once in, it’s kinda a pain to get to and a mess. Don’t over think, unless you built a 500 hp motor. Realize, GM doenst prime every motor off the line. They come from the engine house, get put in a car and an old lady hops in and fires it up, throws it in gear immediately and drives it off the line to park, no “break in oil” no warm up, no priming. Not like you buy a new car and say, oh I better put break in oil in this. Drive it 100 miles, change the oil and move on.

Of course it’s already in at this point! And, about that 500hp motor thing… not quite. But, this is a 408 stroker motor. So, it’s also not a junkyard 5.3 with some new rings by Big Bubbas. Hahahaha

I’m good on all the break in info otherwise. Just really want to know that I have at least some oil pressure before I fire it up for real. I guess I’ll toss a temp mechanical gauge on there if I can’t figure this out right now.

Fresh rebuild.

Of course it’s already in at this point! And, about that 500hp motor thing… not quite. But, this is a 408 stroker motor. So, it’s also not a junkyard 5.3 with some new rings by Big Bubbas. Hahahaha

I’m good on all the break in info otherwise. Just really want to know that I have at least some oil pressure before I fire it up for real. I guess I’ll toss a temp mechanical gauge on there if I can’t figure this out right now.

Every engine rebuilder talks the talk. None of them have the same machining and honing equipment used at the OEM level because it doesn't exist outside of that.

Sure it exists ... It just costs hundreds of millions of dollars, which is a little out of scope for a small business loan.Every engine rebuilder talks the talk. None of them have the same machining and honing equipment used at the OEM level because it doesn't exist outside of that.

If it is a rebuilt motor I would for sure break it in properly. A oil pressure tester gauge can be used for a while until you get the gauge on the dash working.

- Joined

- Jul 22, 2012

- Threads

- 581

- Messages

- 16,323

- Location

- Winter Park, Florida

- Website

- www.cruisermatts.com

turn the key and floor it

Every engine rebuilder talks the talk. None of them have the same machining and honing equipment used at the OEM level because it doesn't exist outside of that.

Sure. That’s fine and all. But, it doesn’t really tell me why my oil pressure gauge decided that it doesn’t want to work. Lol

I get the point you’re making by the way. No worries, like I said, not after break in advice. Just want to know if anyone else has extended that harness and not had their (brand new oem Toyota) sensor work after.

If the oil pressure sender wire touches a ground it will burn out the gauge. Sometimes you can take it apart and fix it.Sure. That’s fine and all. But, it doesn’t really tell me why my oil pressure gauge decided that it doesn’t want to work. Lol

I get the point you’re making by the way. No worries, like I said, not after break in advice. Just want to know if anyone else has extended that harness and not had their (brand new oem Toyota) sensor work after.

I’m here currently. Same Ac compressor and bracket installed (sourced from a 2000 sierra 1500).Here ya go. Power steering pump isn’t installed. Pulled original off for one off a 5.3L.

View attachment 3254946

View attachment 3254947

Something to note for the LM4 crowd: the LM4 block only has 3 of the 4 bolt holes that the sierra 1500 ac bracket uses. The two top ones and the one in the middle hidden by compressor. The bottom rear bracket hole (closest to the exhaust/engine mount) has no matching hole in the lm4 block. It’s better than the two that match up with the trailblazer/ssr/envoy I guess. The bottom two bolt to the 4wd oil pan that come on the envoy/trailblazer/ssr that had to go when using the f-body pan.

If anyone who used a gen 3 aluminum block knows of a better solution please chime in.

Did you source ac fittings that work with this compressor? If so, where?

The bulbus gm fitting doesn’t fit unfortunately.

This place had everything I needed to make up the swap hoses. No affiliation, but great customer service too.Did you source ac fittings that work with this compressor? If so, where?

The bulbus gm fitting doesn’t fit unfortunately.

Fittings

Oring, flare, quick disconnect and metric are four of the main a/c connections. Coldhose uses pictures to identify these fittings. Please match your fitting to the picture as a quick reference when choosing what part you need. The fittings listed on the site have the hose and thread size also...

Air conditioning

...

I'm not completely confident that vibration won't eventually cause these to leak, but for now it's working great.

...

View attachment 1471559

...

Let me know if you guys have any questions.

Any issues with the compression fittings so far? I noticed they specify that the compression fitting is made for steel lines and we're fitting them to aluminum. Did you use any pipe dope or any other sealant during the install?

Thanks for the write-up!

Similar threads

Users who are viewing this thread

Total: 17 (members: 0, guests: 17)