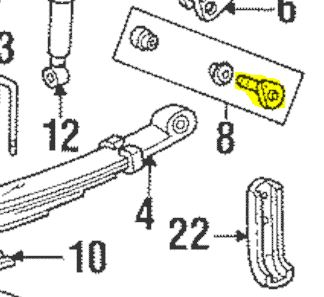

Toyota part number 0448260040, the leaf spring pin for a 60 series Land Cruiser. If left alone for thirty-six years, it is a real pain to remove! While very sturdy, the design is prone to seizing up and options are limited for extraction.

I'm in the middle of installing an OME lift kit on my '86 HJ60 and the factory suspension is putting up more of a fight than anticipated. Progress is slow and there is no rush, but the project is just about halfway done.

The first pin took two weeks to remove, and the second took around twenty minutes. The nuts came off easily enough with enough penetrating oil... As well as a trip to civilization to buy a 1/2" impact rattle gun. An impact driver, 1/2" breaker bar, and 1/2" ratchet are all requirements for this job unless you're very strong and even more patient, then you might be able to get away with just a breaker bar. After no success with a 4 1/2" angle grinder and a cutting wheel, and destroying six Sawzall blades, I found a method that worked! The pin is made out of some very strong stuff.

The pins came out with two main tools and some optional ones, with a 3lb hammer and a 12" Channellock being the stars of the show. What worked was to exercise the pin back and forth with blows from a hammer to alternating ends of the pin. It did not perceptibly move at first, but eventually it backed out enough to get the Channellock on it. Gradually working the pin in and out and rotating it, a pry bar could fit under the plate, and from there it didn't take much more persuasion. A bigger Channellock and perhaps a bigger hammer would have made things easier.

What methods have you Mudders found success with? It seems feasible that a 6" cutting wheel would have reached the pin, or at least 12 of those bimetal Sawzall blades would have made it through eventually. The idea for the hammer and Chanellock came from somewhere on Mud, but I wanted to make a more detailed thread for the next guy to find.

Cheers!

I'm in the middle of installing an OME lift kit on my '86 HJ60 and the factory suspension is putting up more of a fight than anticipated. Progress is slow and there is no rush, but the project is just about halfway done.

The first pin took two weeks to remove, and the second took around twenty minutes. The nuts came off easily enough with enough penetrating oil... As well as a trip to civilization to buy a 1/2" impact rattle gun. An impact driver, 1/2" breaker bar, and 1/2" ratchet are all requirements for this job unless you're very strong and even more patient, then you might be able to get away with just a breaker bar. After no success with a 4 1/2" angle grinder and a cutting wheel, and destroying six Sawzall blades, I found a method that worked! The pin is made out of some very strong stuff.

The pins came out with two main tools and some optional ones, with a 3lb hammer and a 12" Channellock being the stars of the show. What worked was to exercise the pin back and forth with blows from a hammer to alternating ends of the pin. It did not perceptibly move at first, but eventually it backed out enough to get the Channellock on it. Gradually working the pin in and out and rotating it, a pry bar could fit under the plate, and from there it didn't take much more persuasion. A bigger Channellock and perhaps a bigger hammer would have made things easier.

What methods have you Mudders found success with? It seems feasible that a 6" cutting wheel would have reached the pin, or at least 12 of those bimetal Sawzall blades would have made it through eventually. The idea for the hammer and Chanellock came from somewhere on Mud, but I wanted to make a more detailed thread for the next guy to find.

Cheers!