All my pre-owned coolant fittings are still at my plater’s shop getting all sassed up again …

I will not have them back for at least a solid week still …

- so if you can wait kool , if not Mark /

@65swb45 is your all things cooling system fittings source now ….

- he ONLY had solid pre-owned parts as well too ….fyi

- below is the path forward for your alternator adjust bar issue

- these are TOYOTA’s world

famous now Disc, / NLA Washer SUB. ASSY. , Earthquake …

- they were on the non-microfiche paper parts cataloger system of general use service parts , there 4mm thick and have a M8 bolt hole

- if u require more then one only , u must step it up a notch to this longer top tap adjust lock down special service deep hex head bolt u see below

- idea : you arrange it so 1 earthquake washer on the outer or rear facing bar side , 2 or more you spec. In the middle between the lock down tab on the snappy DENSO -60022 and the inside or front facing side of the adjust bar …

Lots of tech 411 above , but this is the way …

Or

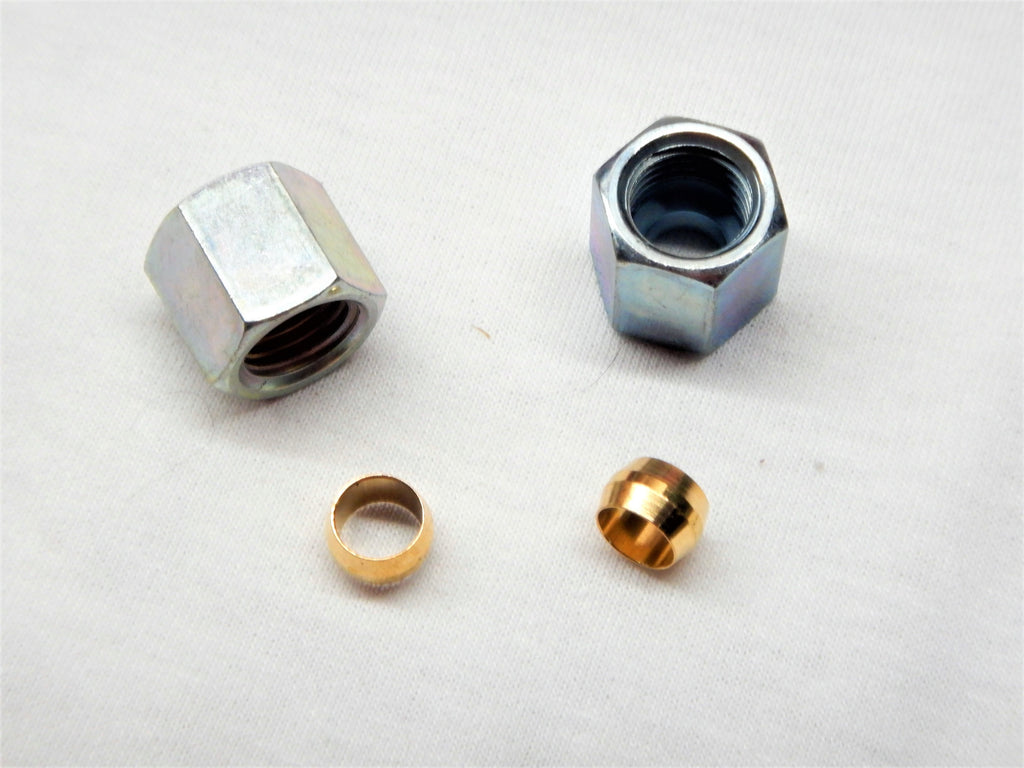

You can play the guess-how-thick-my-collar needs to be game on the water pump adjust bar side M10 bolt hole size spec. ?

- I can tell you that finding a single M10 thick wall deep collar like the various more than a few size specs. that land cruisers had going on over the years 1962-1992 F , 2F 3F carb. is not a easy task …

So those are your options as I see them ….

Also , simply stacking a pile of M10 common flat washers on the pump side is ill advised …

Unless you do indeed have the original or NOS longer factory DISC. NLA optional water pump bolt for that specific location ?

- if u use the shorter ones like the other 3 are , your 2-3 spins of M1.5 coarse thread pitch will give and pull out when the correct FSM newton meters torque yield is applied …

- I have made that amateur hour mistake in my past , I will let Mark explain how he would approach a needed block face pulled female threads repair there ….

- NOT is my thought on that topic …