This FAQ deals exclusively with an OME lift. There are other lifts provided by Slee, and Man-a-Fre. Links for those lifts are included at the end of this FAQ. One of those lifts might better fit your application. OME is the most widely used and so we will focus on that for this discussion. The concepts here can then be applied to the other lifts via the links.

Please bear in mind that every truck is slightly different and each truck will potentially behave differently to each set-up. Adding any lift will cause driveline issues that are not serious in a stock setup to be exacerbated in a lifted set-up. e.g. marginal U joints and drive shaft balance issues will begin to make noises and vibrations. Please see the Drive Shaft section in the FAQ.

So you want to lift your truck? First there are a lot of questions you need to answer. The lift you put on should match the near term condition of the truck. In other words, if you won't be installing bumpers and a winch for a while, you need to size the lift without them.

Also, when planning a lift, you should discuss it with some of our local supporting vendors, Slee Off Road, Cruiser Outfitters and Man-a-Fre all carry and support OME lift kits and components. In fact, we would like to thank Christo Slee and Kurt from Cruiser Outfitters as some of the info here-in was utilized from their tech sections. Christo supplied the information on Castor in support of this thread. Also, cruiserdan and Beowulf posts were used as inputs along with other forum members.

There are several things to consider when doing a lift:

Please bear in mind that every truck is slightly different and each truck will potentially behave differently to each set-up. Adding any lift will cause driveline issues that are not serious in a stock setup to be exacerbated in a lifted set-up. e.g. marginal U joints and drive shaft balance issues will begin to make noises and vibrations. Please see the Drive Shaft section in the FAQ.

So you want to lift your truck? First there are a lot of questions you need to answer. The lift you put on should match the near term condition of the truck. In other words, if you won't be installing bumpers and a winch for a while, you need to size the lift without them.

Also, when planning a lift, you should discuss it with some of our local supporting vendors, Slee Off Road, Cruiser Outfitters and Man-a-Fre all carry and support OME lift kits and components. In fact, we would like to thank Christo Slee and Kurt from Cruiser Outfitters as some of the info here-in was utilized from their tech sections. Christo supplied the information on Castor in support of this thread. Also, cruiserdan and Beowulf posts were used as inputs along with other forum members.

There are several things to consider when doing a lift:

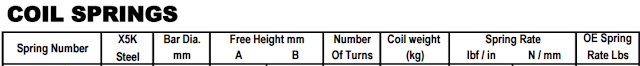

- Springs - Main factor for determining lift

- Shocks - Main factor for determine of axle play

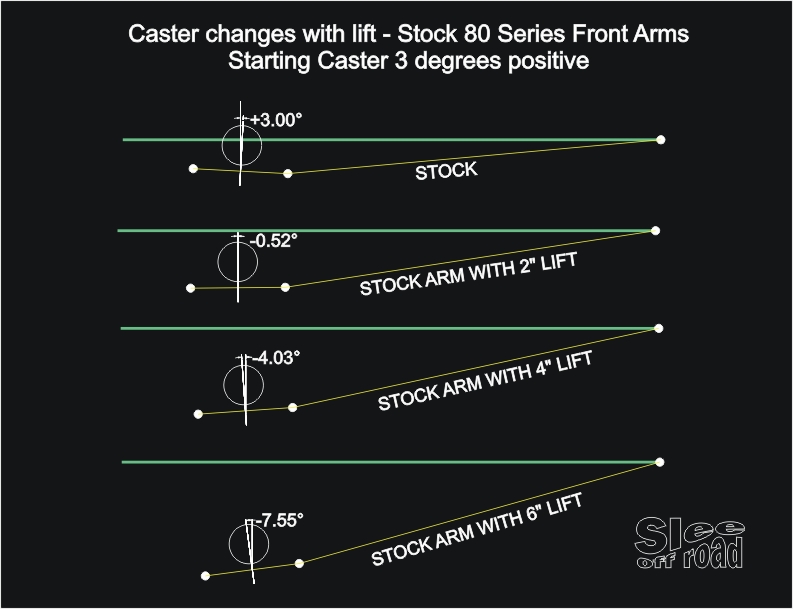

- Castor - correction required to return steering to normal based on lifts effects on driveline and steering components. Usually done on OME lifts via a Castor correction kit (Bushings in the control arm).

- Steering Damper

- Brake Lines - Longer lifts and spacers may require longer brake lines

- Swaybar Brackets - Extensions to swaybar for taller lifts to prevent damage

- Control Arms - Replacements are available to compensate for lift, but not needed for most OME lifts.

- Tire Size

- Tire Bumpstops - Modifications typically only required for 35: tires and up.

- Spacers - Used at top of springs to make spring lift taller

Last edited:

It took 5,640 rounds of M2 Ball (430 lbs) to drop the vehicle back down that 1.25 inch gain.

It took 5,640 rounds of M2 Ball (430 lbs) to drop the vehicle back down that 1.25 inch gain.