150A Sequoia Alternator!

After my trouble finding a proper sized alternator on this side of the world for any decent price, I've been running the 80A alternator for the 18 months or so. It mostly works, but during startup the load from the intake heater and batteries was killing it, howling madly and far exceeding its capabilities so I've had that disconnected for most of the time. It would still show a low voltage idiot light and struggle to hold voltage while charging both batteries for a few seconds after startup. That happened back here:

Mail Order Ride - My HDJ81

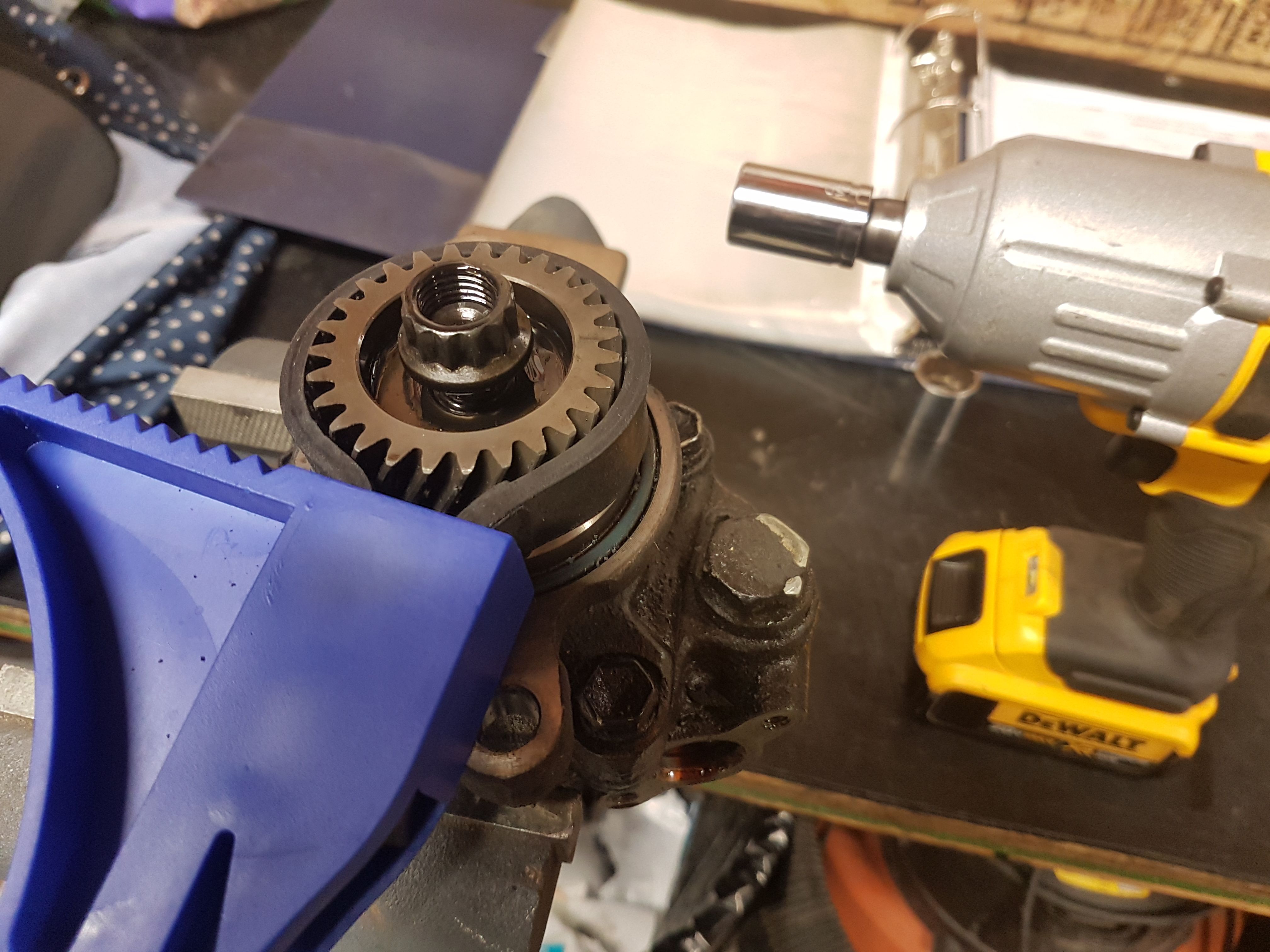

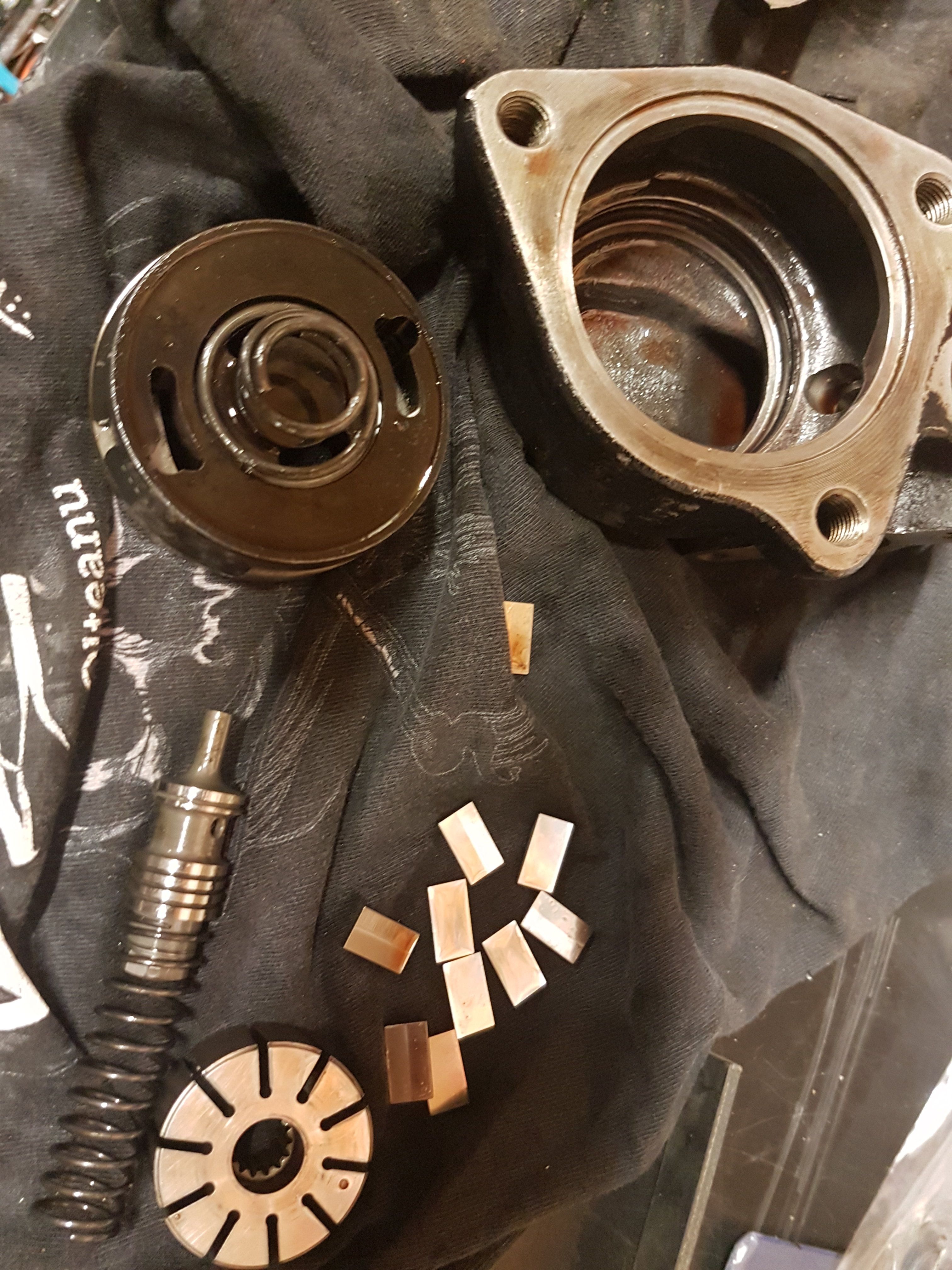

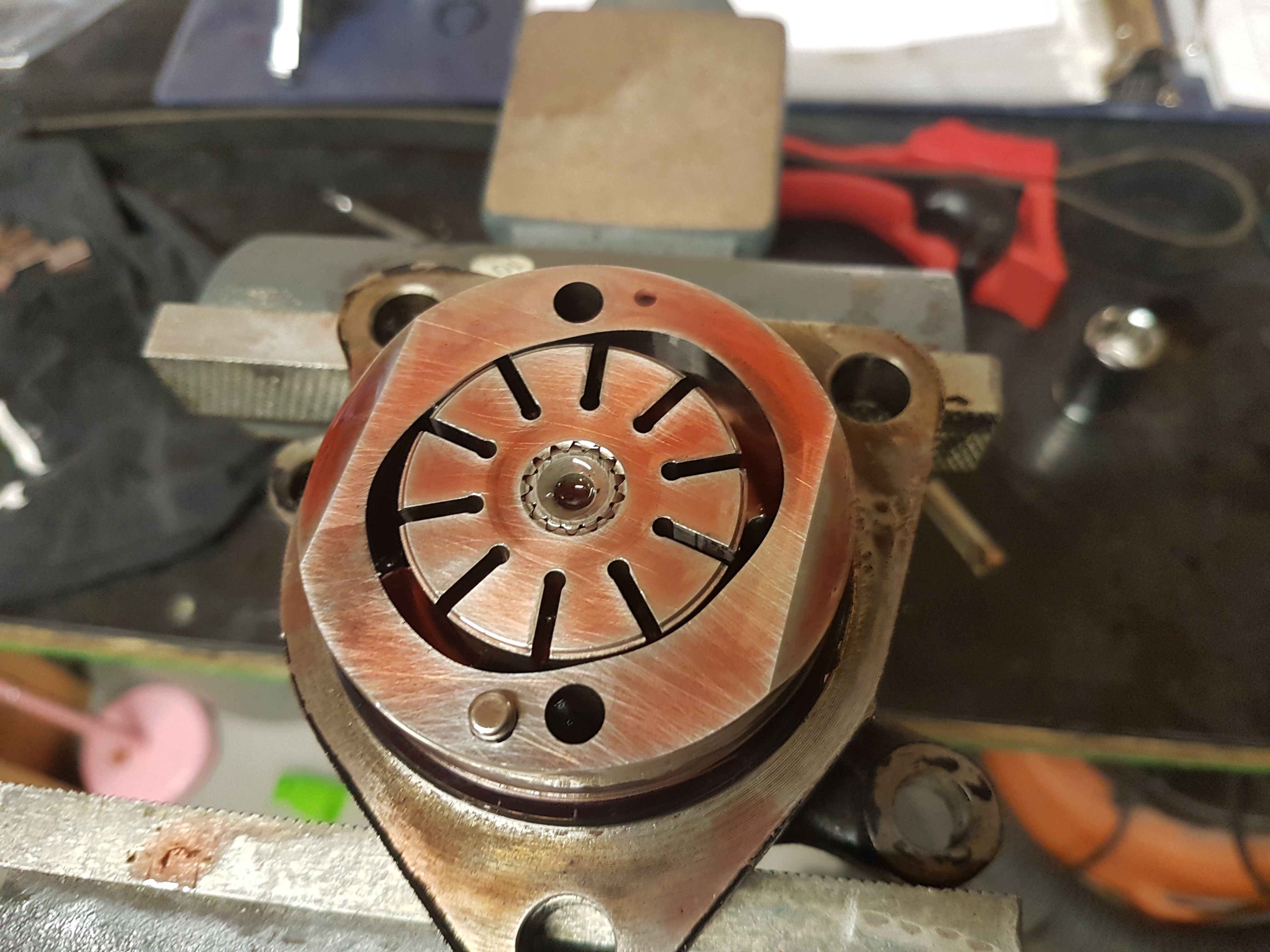

A little while ago I picked up a 150A alternator from a smacked up 2005 Sequoia for $85, part #27060-0F050. Brought it to a rebuild shop where a dude spun it and said "it was doing 125 at 1800. It works" so I thanked him for his time and left. Ordered a 4 pin connector based on information from

@Photoman 's bracket and connector thread, part #90980-11964.

I finally got around to taking everything apart recently. Get out all your 10/12/13/14mm shallow and deep sockets, extensions and box end wrenches. Disconnect both negative cables from batteries, pull out the air box, intake tube to turbo, the a/c belt, a/c tensioner pulley off completely, took out the bolts for the a/c compressor, tied that out of the way, loosened the alternator, pulled off the alt belts, took the fan and water pump pulley out of the way (but not fully out, I got lazy and didn't want to pull fan shroud), pulled the alternator out, and took off that little skid plate thing underneath (but actually didn't have to in hindsight).

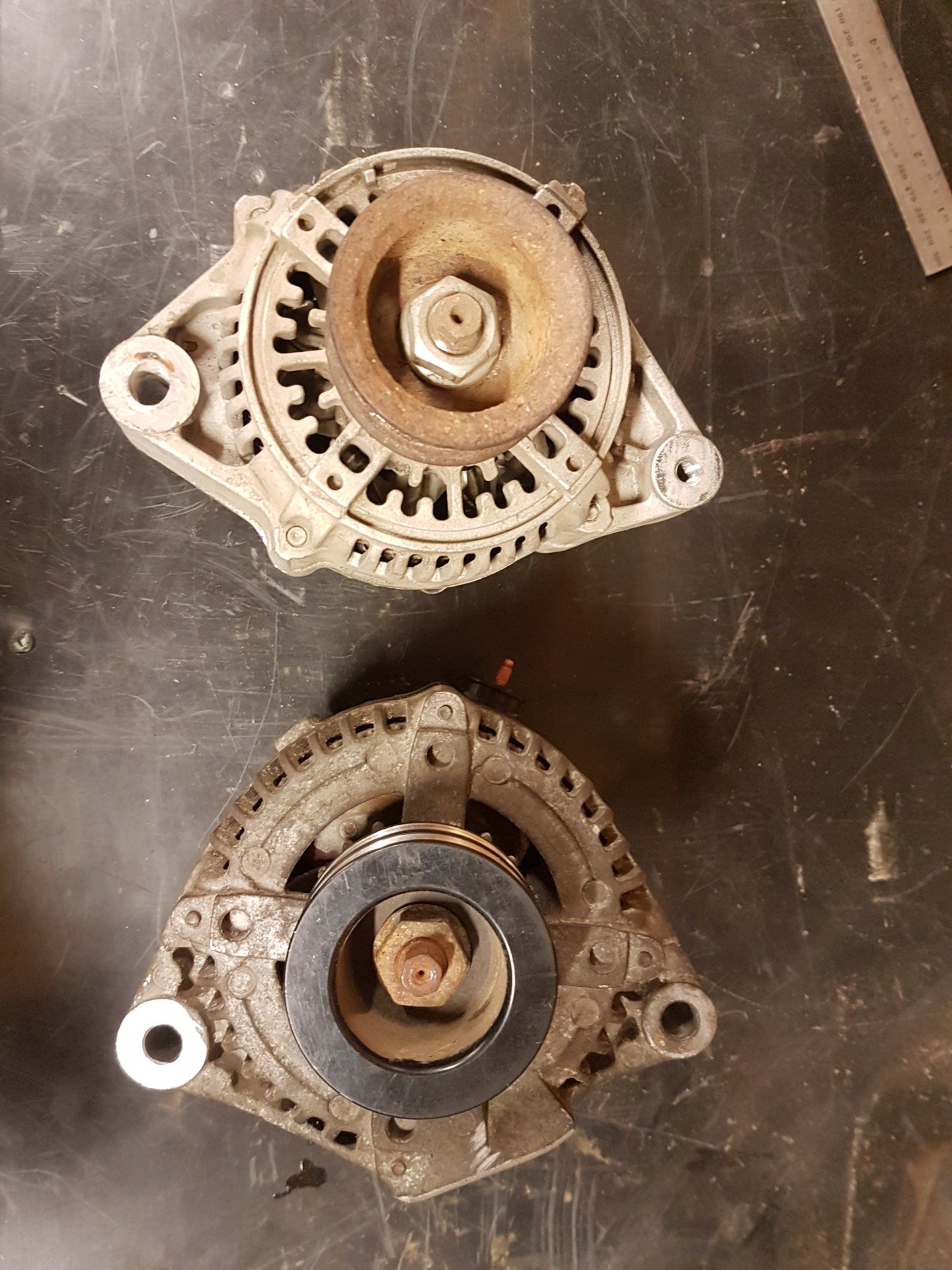

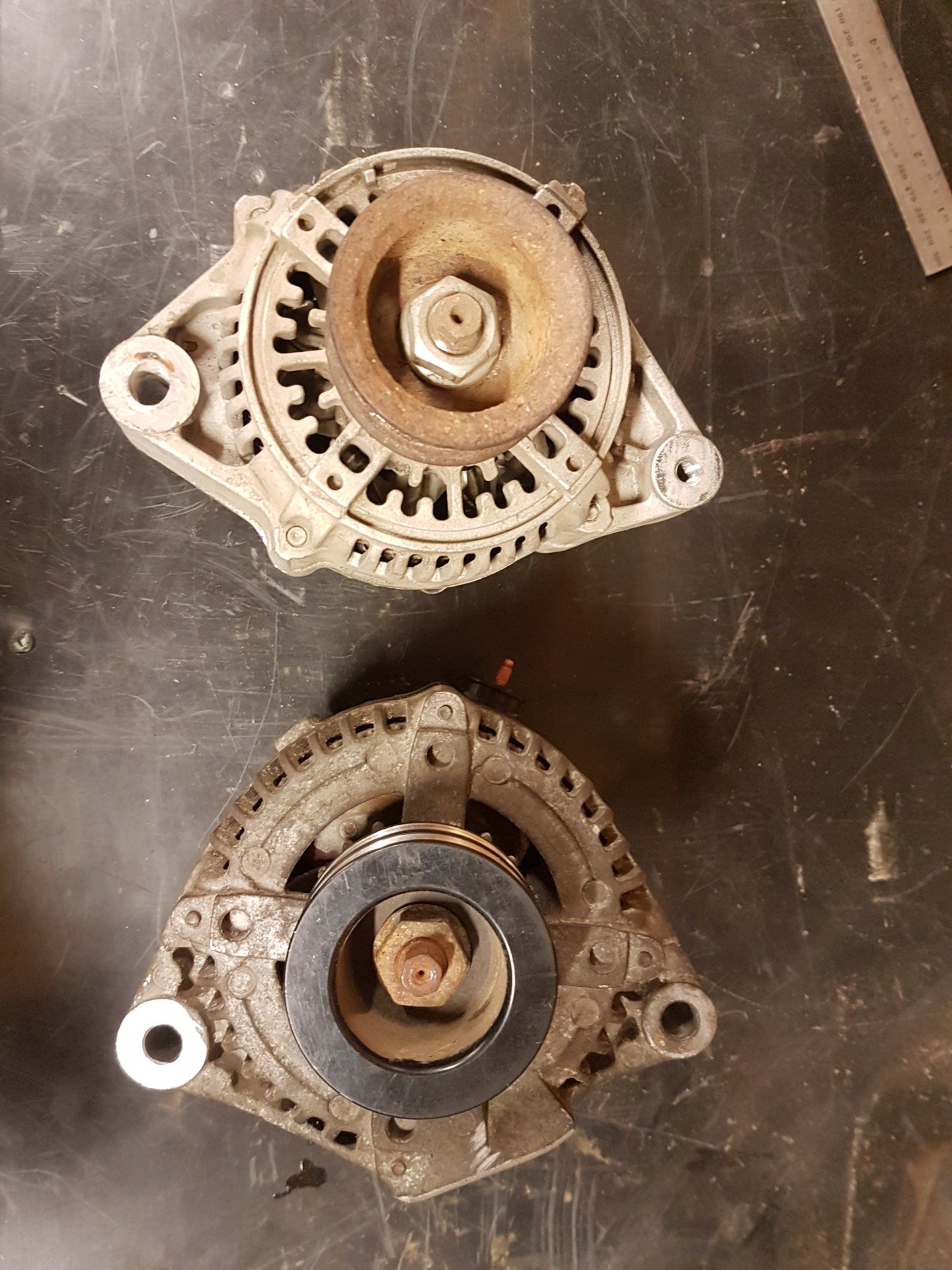

The top is the 80A unit, the bottom is the 150, pulleys have been swapped already as the Sequoia uses a serpentine belt. You need to cut off the inside mounting tab from the new alt, it would be at 6 o'clock in that picture. After a bunch of attempting to fit things, drawing up custom brackets and cutting them out of tin, attempting different ideas, I ended up coming across photos posted by

@CycloSteve and

@Tapage where they just used modified stock brackets, so I realized I was overthinking things. I needed to open the mounting holes a bit so I could rotate the bracket up, and opened some of the bottom of the slot in the bracket. I also needed to file the corner of the casting for the bracket. The adjustment bracket used is the large #2 bracket, part#16381-17020.

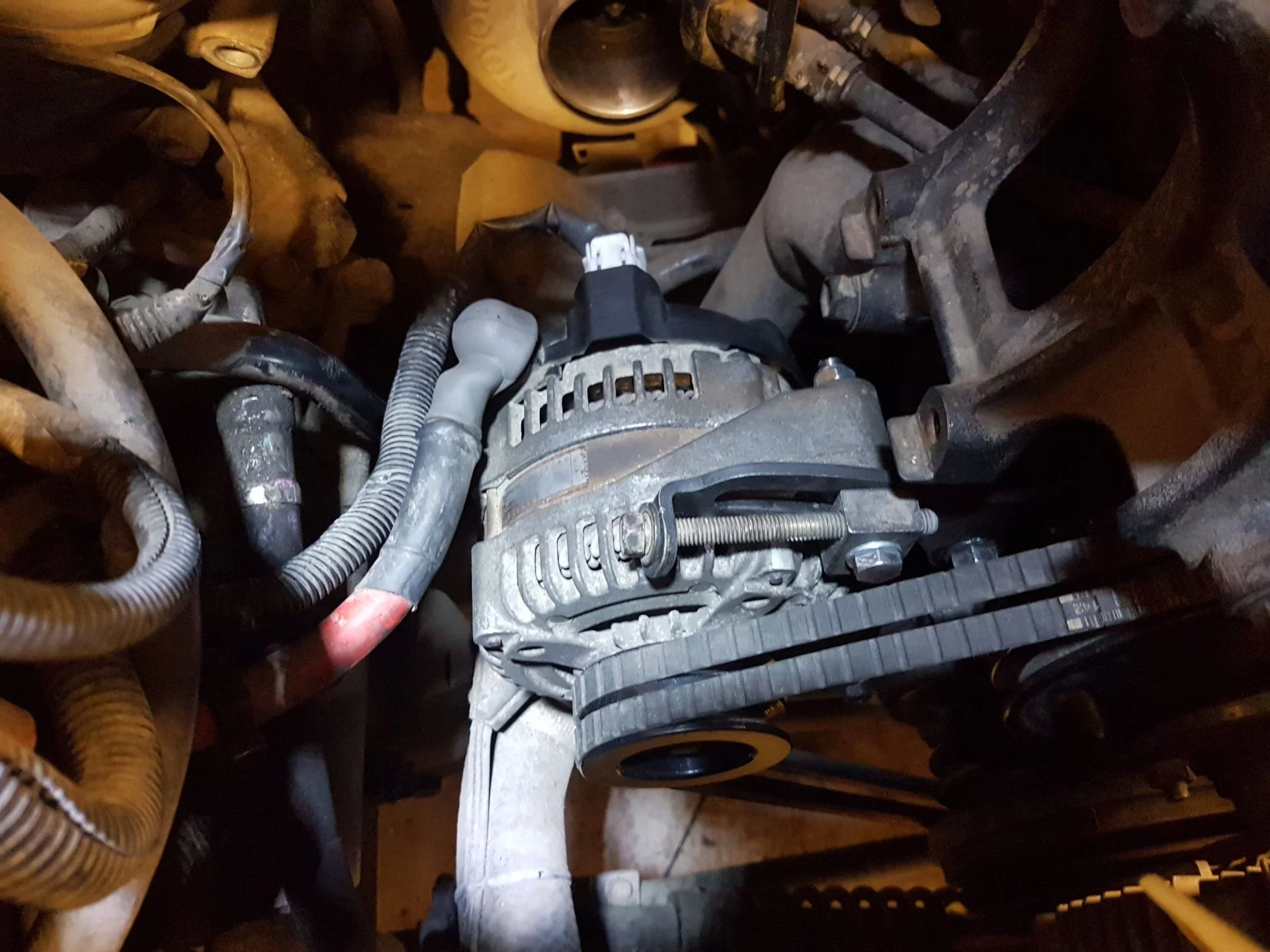

After that, it's a real tight fit. The adjustment bracket needs to be totally loose or off at the water pump side to even get the alternator into place so the bottom bolt can go through. I was using the 39" belts and was able to JUST get them over the pulley. A 39.5 would have been nicer, but I was able to reuse what I Already had. I got a m8x1.25x75mm bolt and some washers and a nylock nut for the "tighten the thing in place after adjusting" function since the new alternator isn't a threaded hole, so you gotta go all the way through. I wasn't able to get a larger diameter bolt through without taking more material out of the adjustment bracket, so I'll just have to check on this one sometime later. Eventually it worked and I was able to get belts in place, tightened everything up, and in place.

Took the pins out of the stock plug and inserted them into the new 4 pin plug. The photos and information posted by

@Otamiway in

150 Amp Alternator - Thanks Photoman are awesome and mostly correct for a 95 hdj81. The "S" wire was white, while "IG" was black/blue and "L" was yellow/blue.

With all this in place, put everything else back together again and fired it up.

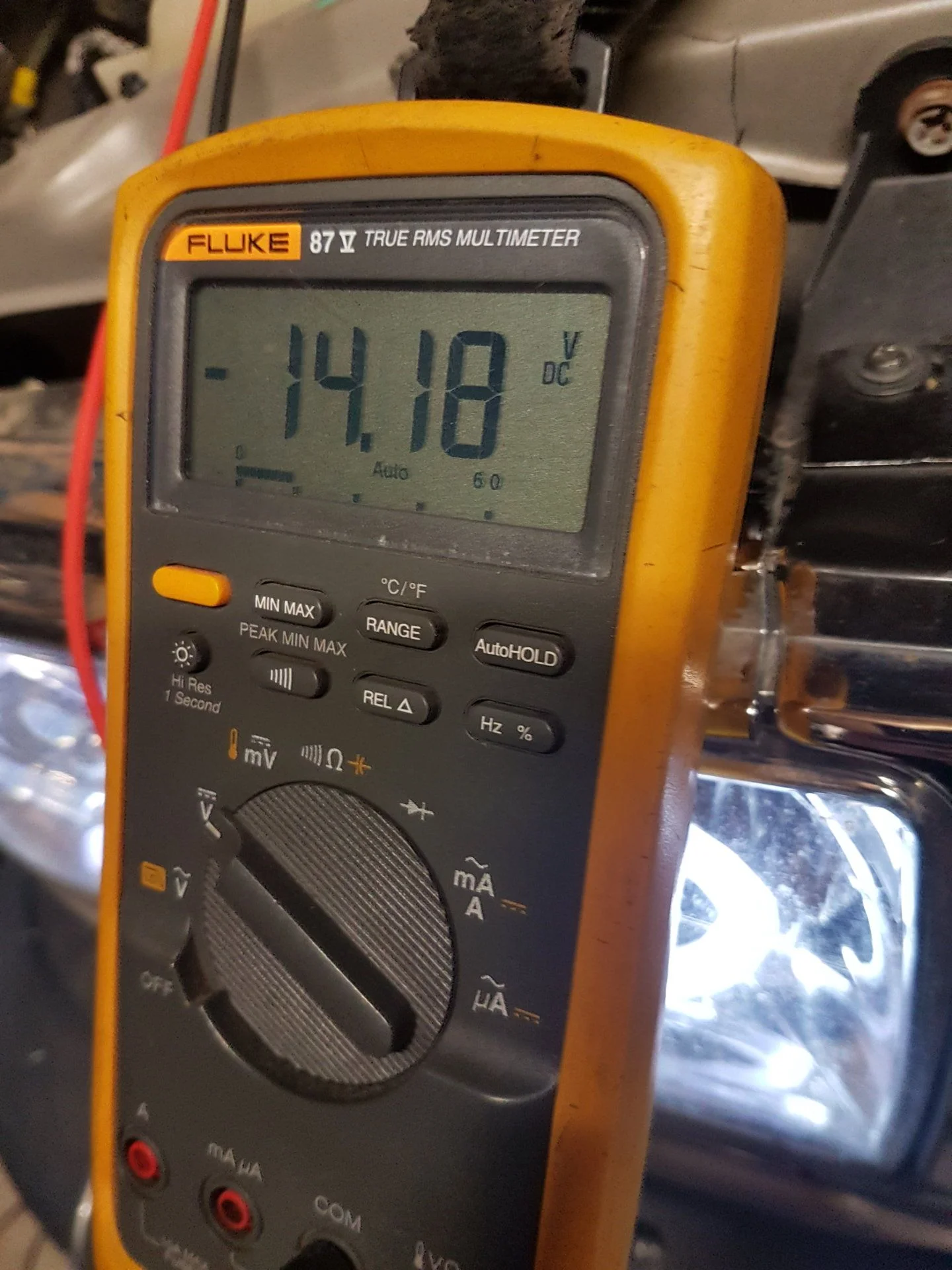

Got 13.99V at first, then 14.18V after a short drive and it was warmed up. No more dummy light while batteries are getting topped off after startup. Better than the 13.7 the old alt was running at too. I still haven't plugged in the intake heater. I'm choosing not to ignore the possibility it might be pooched and that's what contributed to the death of my original alternator, so I want to run this as is for a bit, make sure there's no problems before trying it out. I also didn't have a DC clamp with me and I didn't want to stress the alt without watching what was happening.

A smaller pulley might be a good idea, since I think the gas Sequoia would normally work at a higher RPM than the diesel does.

So far seems good though. And it cost me a grand total of $101.