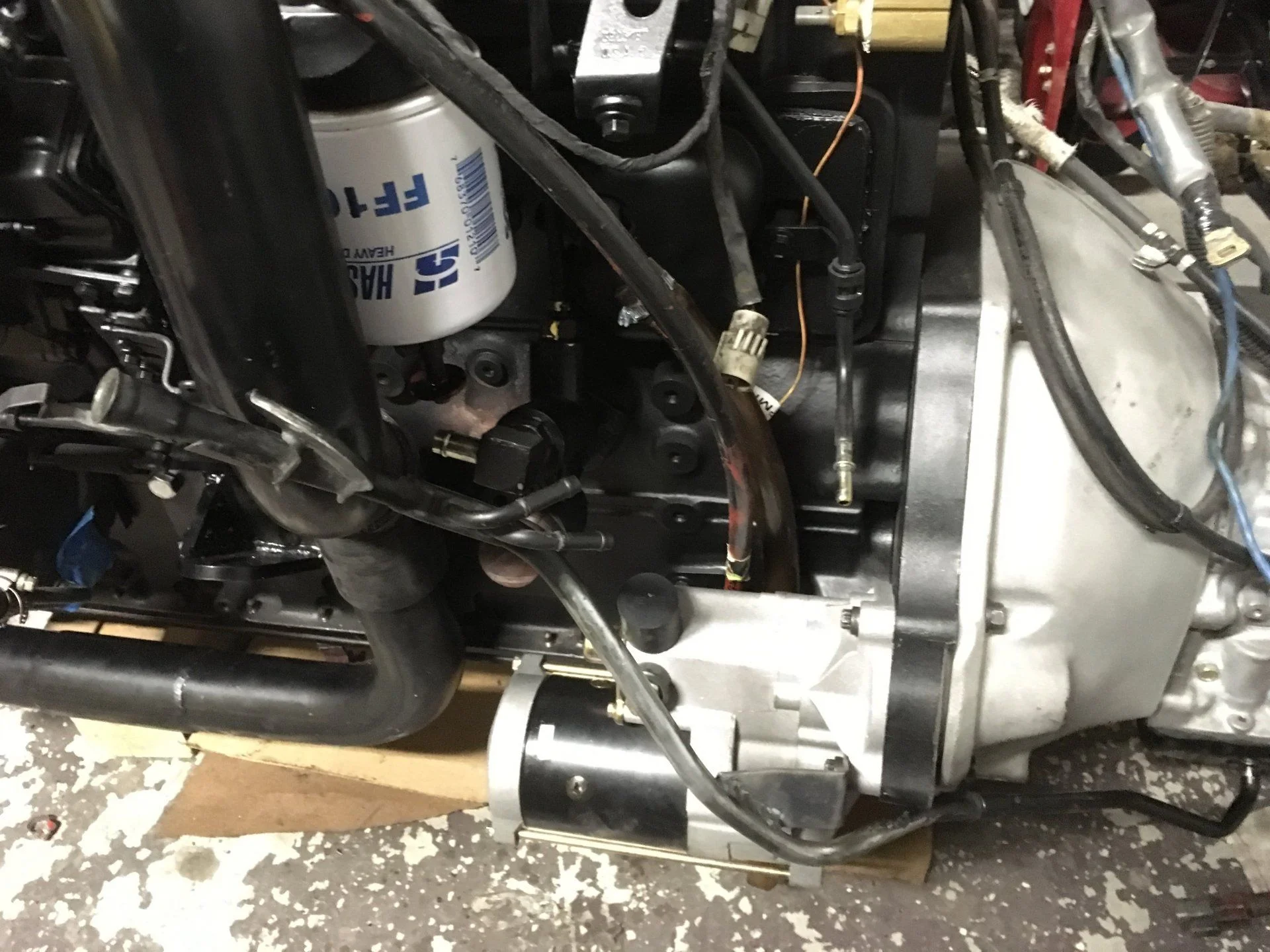

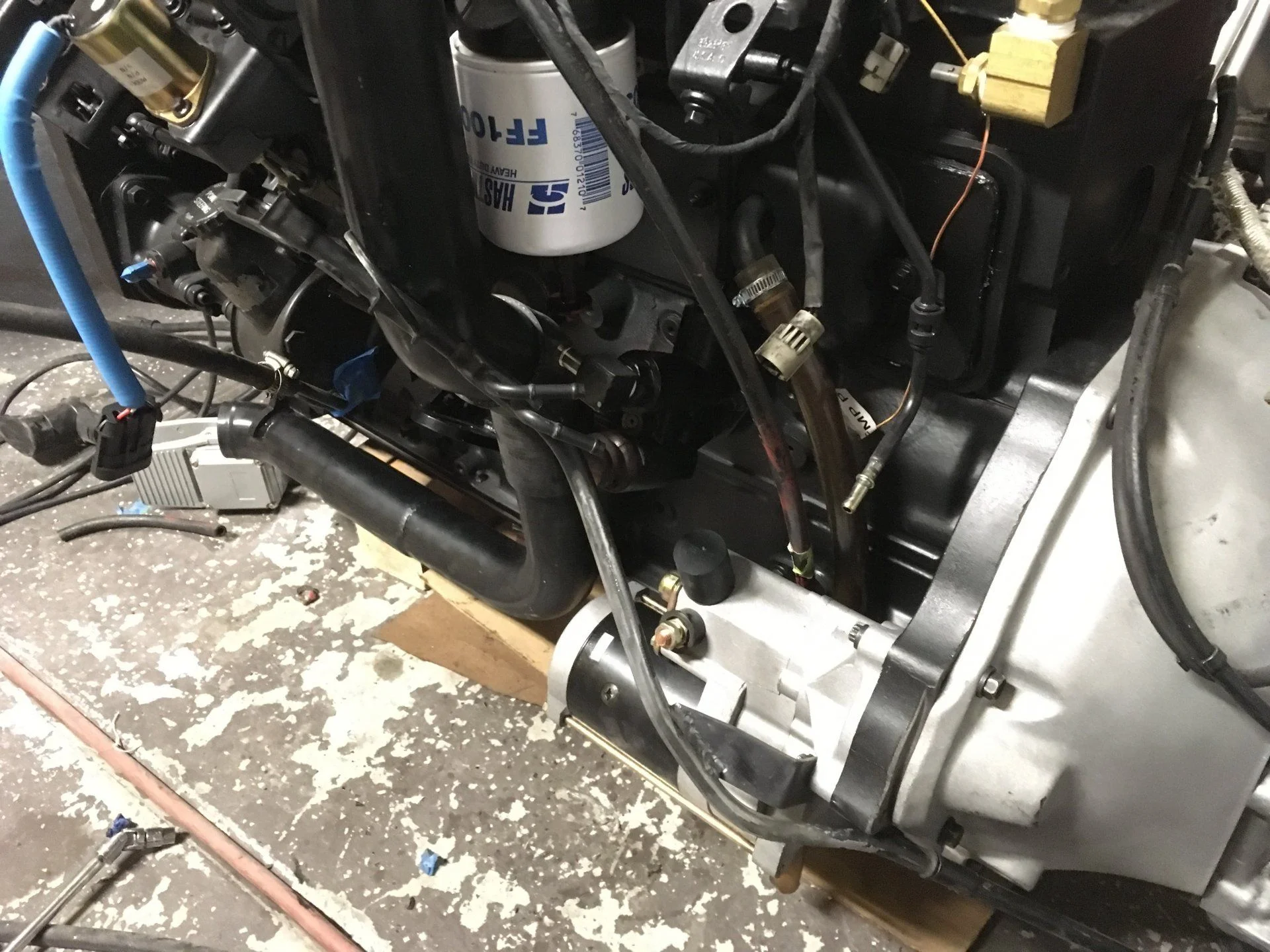

Mine has the relocation bracket. It brings the fan down and to the passenger side so if you are running the mechanical fan it is closer to the stock toyota position. It looks to me from your picture that you are running the stock one, which would definitely use up more belt, so I bet that is the difference. The original one is a cast piece, and the one that comes in the kit is welded together.

What is the coolant line and sensor up top for, is that your heater return, and coolant temp? My heater return comes off down by the lower radiator hose, and the coolant temp sender and cut-off are on the drivers side back towards the firewall.

Nothing wrong with this setup, similar to stock dodge.