- Thread starter

- #101

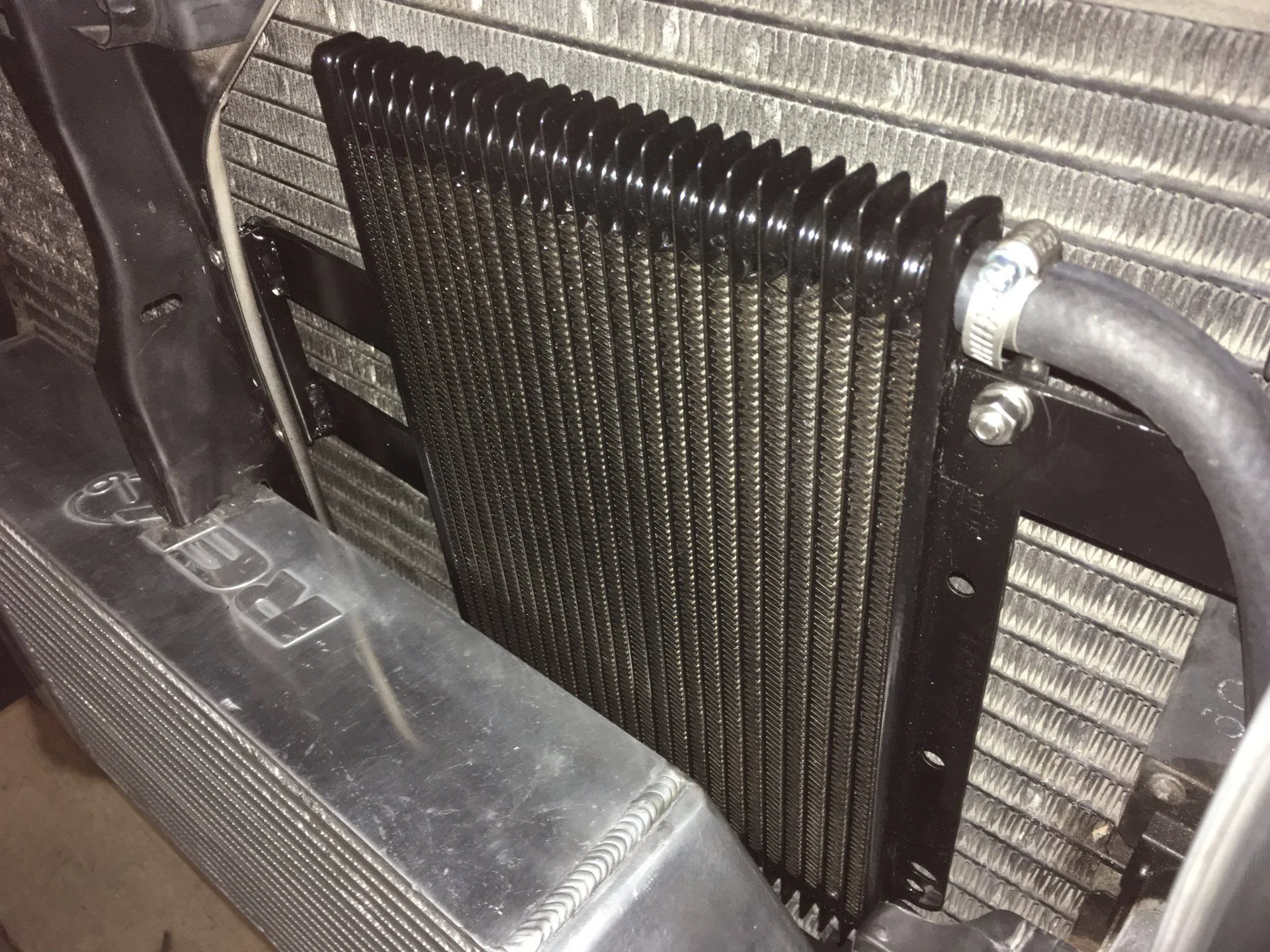

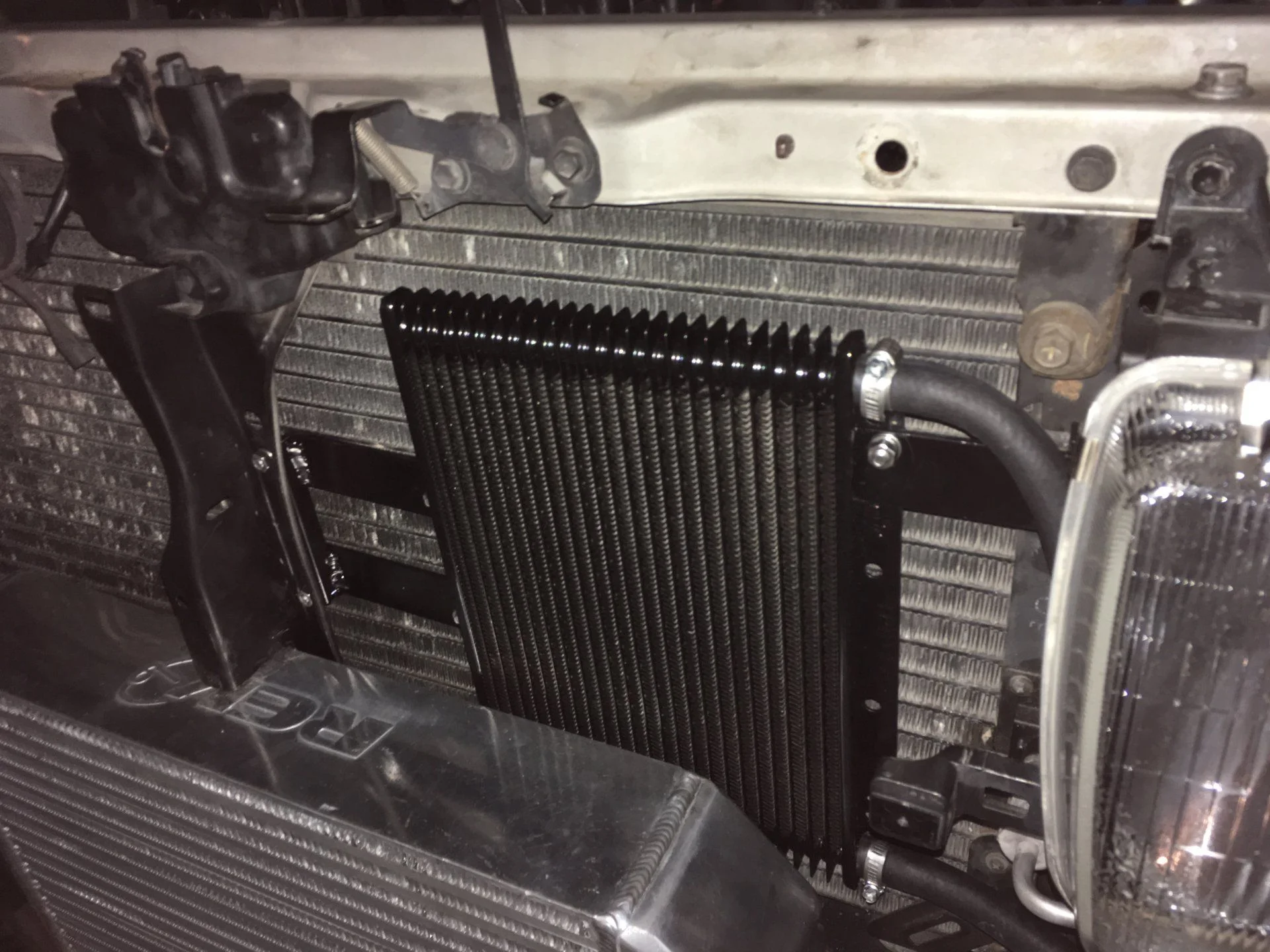

I am sure it works, but he could just as easily provide the adapter fittings and a hose discussed above or something similar. His solution introduces unnecessary complexity and more potential failure points IMO, but to each their own I guess.The hose provided in the kit works fine, it keeps things easy for the average joe doing the swap, I have worked on a couple of swaps and I like this set up