78fj40mg

TLCA #23510

- Thread starter

- #341

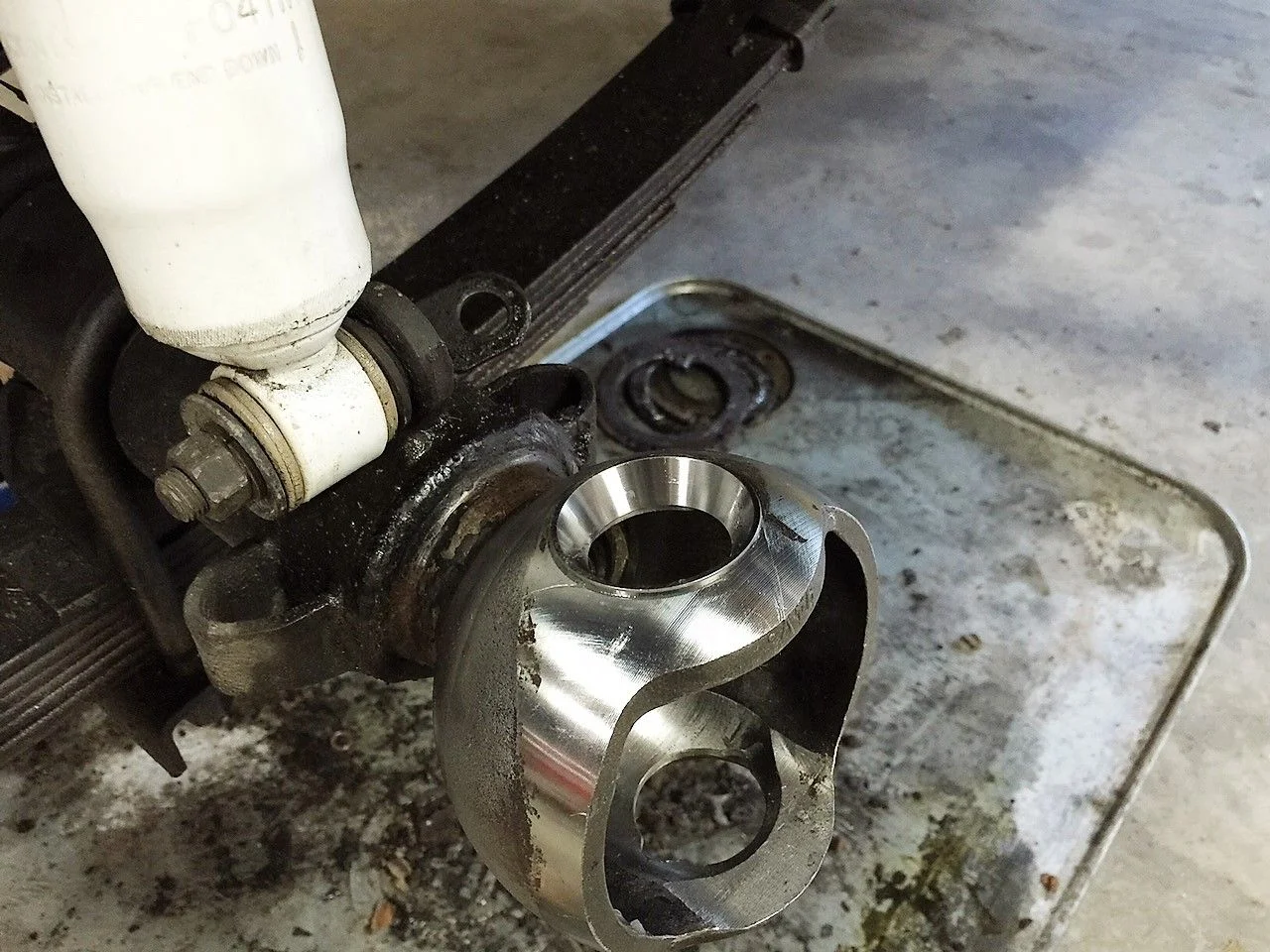

Drilled steering knuckle plug to install a permanent Zerk grease fitting.

Center punched to guide the drill bit (13/64th bit)

Used a little jig to hold the plug for drilling

Used a 13/64 drill bit

Successfully drilled plug

Next to tap the hole, used a 6mm X 1.00 tap

Tapped the Zerk fitting hole while using plenty of cutting oil

Zerk fitting installed

A little paint and ready to install

Last edited: