rkymtnflyfisher

Trout Bum

Pretty solid rattle can skills also! That looks great!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Thanks Bud!

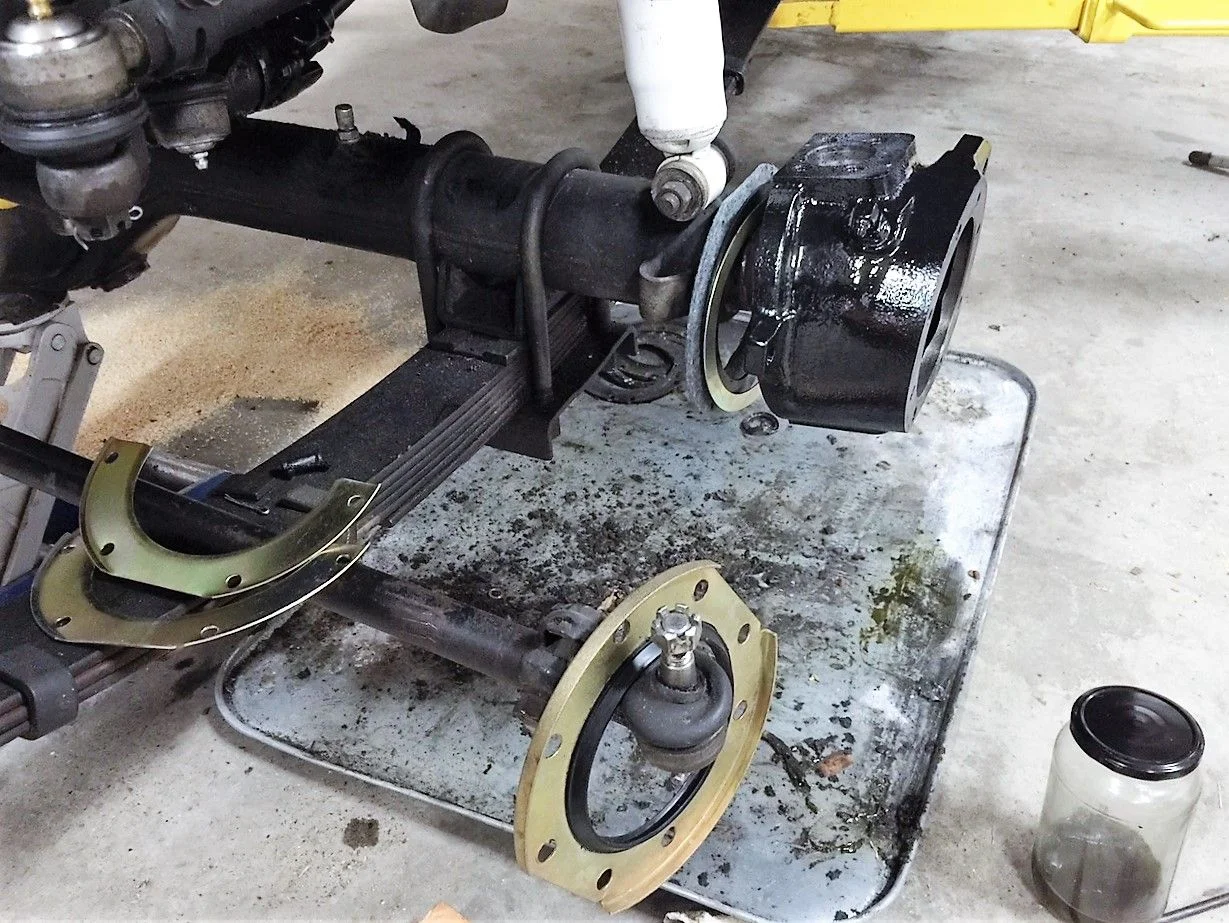

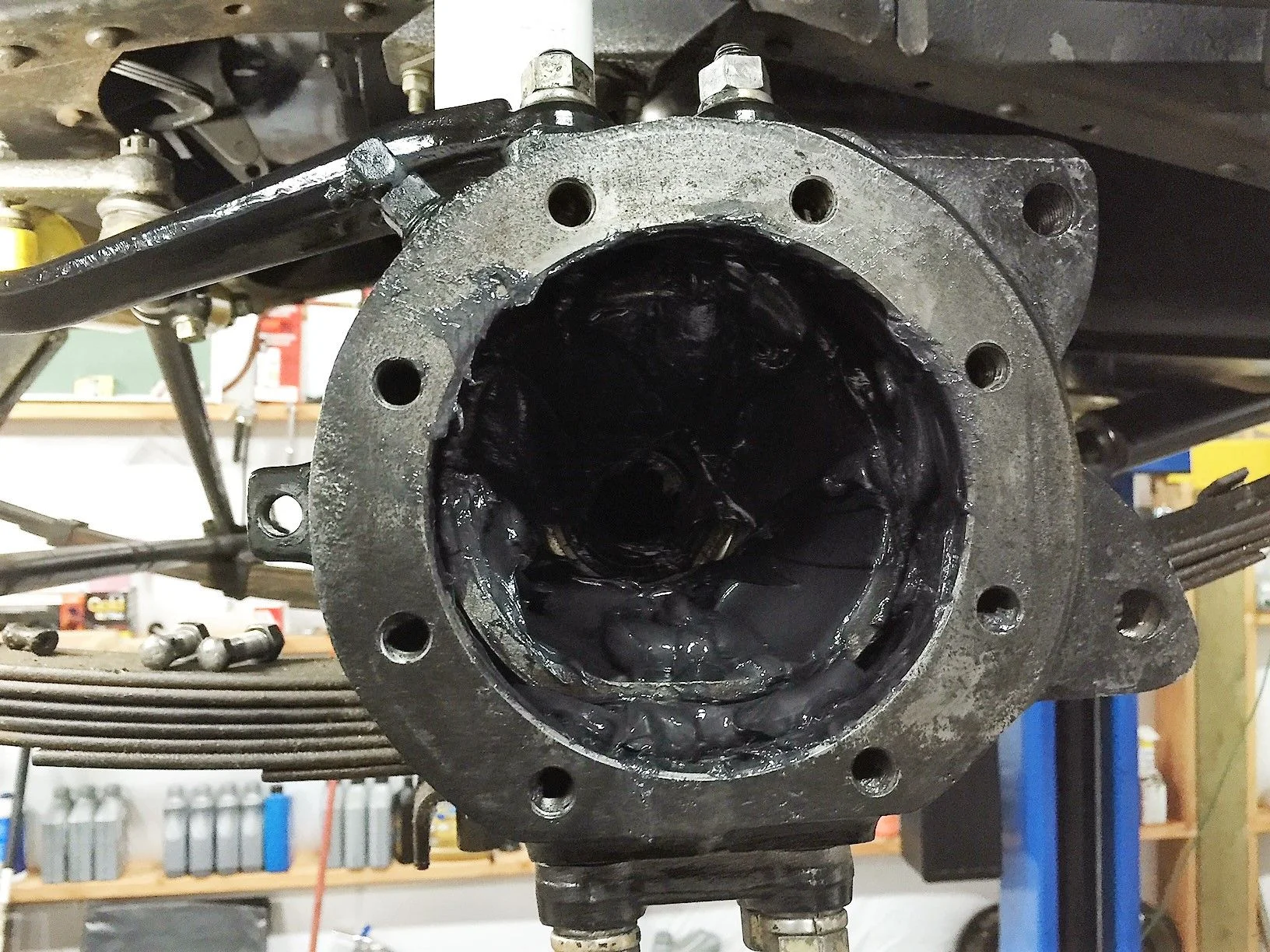

The build looks great. Curious about the paint. Were these engines painted at the factory? I know they get all corroded, but just curious because if the paint peels or lifts due to rust, etc, it may be a visual problem rather than a benefit. Would media blasting the block be useful? Wondering mainly because I'll be into this exact project in the next several months.Thank you for the kind words! I use aluminum color automotive engine paint 500 degree range bought it from the Home depot for $4.99 and it works great, they also carry 2000 degree paint.

Did you bake the knuckles? I noticed the can recommended using heat to help the paint to cure.

Jeff