great thread idea... got any de-smog screw-ups photos

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How not to build the 2F

- Thread starter FJ40Jim

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Mark W

Yep, I really don't really care that much I guess.

I actually serviced one of those 'beat on sideways' rocker arm hacked 2Fs while I was in Atlanta on vacation before GSMTR last year.

One day Jim, your gonna have to come by and see the Mark's Off Road "Wall of Shame" collection of stuff I've pulled off of crusiers. Hell, between you, me and Whatley, we've probably got enough bastardized parts to build a rig that would scare Frankenstein!

Sometimes I see stuff done on rigs that I pronounce "acceptable for a Bush Truck". That is to say I might take a similar approach if I was out in a village without any parts availability or repair support, or a remote off the road system homestead. Things like bedframe parts battery welded to splint broken frames together, carb linkages that have carved wood components in them and stuff like that.

But when the truck has spent it's life on the road system and with access to parts and a support infrastructure... I am a little slower to make excuses for the hackwork that comes through.

I have seen a couple of HEI distributor gears looking like the one early in this thread. and a couple of roll pins used to locate the dist gear in these and in rebuilt Toyota distributors that have sheared. (DUI units too). There is a reason the factory used a solid pin!

I have not personally encountered that type of rod failure from overly advanced timing. I usually seen burnt and broken pistons from that mistake.

At one point I had 10 dead 2Fs in the graveyard with destroyed bottom ends due to over revving resulting in stretched rod bolts.

Torn up knuckles due to using the incorrect haynes manual torque numbers used to be common for me to see.

Mark

Mark W

Yep, I really don't really care that much I guess.

Here's a recently failed crank that was just rebuilt by the guy who builds all the racey car engines.

The problem is after the crank was turned down and polished, then the oil holes in the rod journals were chamfered.

Excessively.

The chamfer takes up more than 1/3 of the bearing width. And it does not have a properly softened edge. The crank shoulda been turned down to within one or two thousandths, then polished to final size. No need to enlarge or chamfer the oil hole, just let the polishing belt soften the edge of the hole.

And yes, that is the shaved off rod bearing hiding inside the hole.

That is..... well.... I guess "impressive" is a good word to use.

Mark...

- Joined

- Oct 25, 2008

- Threads

- 40

- Messages

- 1,331

- Location

- Central Oregon

- Website

- www.oregoncruisers.com

I love this thread! Though it does not make me very comfortable with the thought of having someone rebuild my motor! Great stuff been subscribed from the start!

LAMBCRUSHER

SILVER Star

be sure to save a few bucks and buy a cheap oil pump. They can sell em for less cause they took less time to remove material from the bore wall of the distributor shaft hole, which is like getting extra metal for free it also serves as extra insurance for your engine by keeping the clean passage ways and bearings from becoming covered in oil and also ensures your motor wont catch fire by preventing sparks from happening inside of the cylinders- and you'll always know where TDC@#1 is just by pulling the dizzy cap...

it also serves as extra insurance for your engine by keeping the clean passage ways and bearings from becoming covered in oil and also ensures your motor wont catch fire by preventing sparks from happening inside of the cylinders- and you'll always know where TDC@#1 is just by pulling the dizzy cap...

it also serves as extra insurance for your engine by keeping the clean passage ways and bearings from becoming covered in oil and also ensures your motor wont catch fire by preventing sparks from happening inside of the cylinders- and you'll always know where TDC@#1 is just by pulling the dizzy cap...

it also serves as extra insurance for your engine by keeping the clean passage ways and bearings from becoming covered in oil and also ensures your motor wont catch fire by preventing sparks from happening inside of the cylinders- and you'll always know where TDC@#1 is just by pulling the dizzy cap...- Joined

- May 3, 2013

- Threads

- 64

- Messages

- 540

- Location

- Upstate South Carolina

- Website

- www.nexgencontractors.com

Timing gears

I am at the timing gear stage of my rebuild, my crankshaft gear doesn't have the normal timing mark/dimple but instead has a small toyota emblem on the face of the crank. Is this the timing mark?

I am at the timing gear stage of my rebuild, my crankshaft gear doesn't have the normal timing mark/dimple but instead has a small toyota emblem on the face of the crank. Is this the timing mark?

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

- Thread starter

- #69

Yes, that is the OE gear timing mark.

- Joined

- May 3, 2013

- Threads

- 64

- Messages

- 540

- Location

- Upstate South Carolina

- Website

- www.nexgencontractors.com

Thanks Jim

landcruiserrich

Bench Wheeler

Wow, awesome thread! I lucked out when my HEI distributor failed. When I was younger and stupider I tried to save money by using an HEI distributor instead of buying the non USA Toyota one to get a vacuum advance dizzy . I had read that the HEI distributor from a gm straight 6 just drops right in to the F engine. This is where I stopped researching. I went to the wrecker, got a dizzy, dropped it in and started driving it. Then one day I was driving along and the engine just died. I got it towed home, found out there was no spark and started changing expensive HEI parts to try and fix the problem. After replacing everything easy I decided to remove the distributor and take it apart. This is where I found that the distributor shaft had drawn itself down into the distributor due to the fact that the helical drive gear was only half engaged and the rotor destroyed the stator. So it ended up costing me 400$ in HEI parts plus the dizzy and then after more research, the cost of a new non USA dizzy and vac advance carburetor base. It was an expensive lesson that taught me not to cheap out on parts. Oh yeah, the part where I got lucky is the distributor ate itself before it could do any serious damage to the cam or oil pump.

The 2F seams to be a great motor but sometimes my wallet doesn't like the fuel economy, can you stick gerbils or hamsters in side the timing cover to help with that?

I am in the process of reinstalling mine and idk maybe?

If I put more than one in there will they end up fighting to much and not working enough? Or if i just stick one in there will it get lonely and thus not work enough?

I am in the process of reinstalling mine and idk maybe?

If I put more than one in there will they end up fighting to much and not working enough? Or if i just stick one in there will it get lonely and thus not work enough?

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

- Thread starter

- #73

The 2F seams to be a great motor but sometimes my wallet doesn't like the fuel economy, can you stick gerbils or hamsters in side the timing cover to help with that?

I am in the process of reinstalling mine and idk maybe?

If I put more than one in there will they end up fighting to much and not working enough? Or if i just stick one in there will it get lonely and thus not work enough?

Took apart this engine and found the gerbils had hidden some extra food in the water jacket.

That's like NOS for when they start getting tired.

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

- Thread starter

- #74

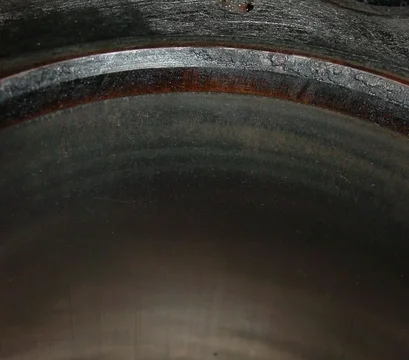

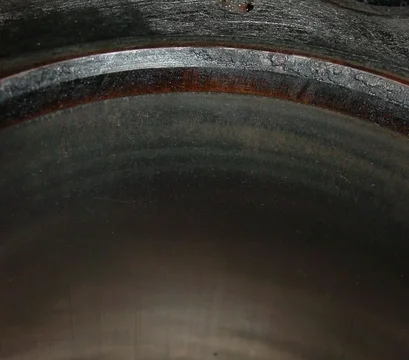

Same 2F has processed a couple of small washers? Nuts? Something was ingested, rattled around in cylinders 1,2 & 6 for a while, before it was finally spat out the exhaust. The engine ran for a few more years, but it has finally expired because the gritty cylinder walls demolished the rings and piston skirts.

1.top of good piston

2. damaged piston

3. good cylinder

4. damaged cylinder wall

1.top of good piston

2. damaged piston

3. good cylinder

4. damaged cylinder wall

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

- Thread starter

- #75

The oil filter mount is a flat iron boss and a flat filter base. Very easy to seal.

Therefore it should have a pile of RTV applied to it. Maybe it will extrude enough into the passages to prevent the flow of oil through the filter. This will keep the filter from getting dirty, representing a good savings on maintenance.

Therefore it should have a pile of RTV applied to it. Maybe it will extrude enough into the passages to prevent the flow of oil through the filter. This will keep the filter from getting dirty, representing a good savings on maintenance.

Cylinder damage almost looks like either throttle shaft screws or maybe some from an air cleaner - seen that more than once in many engines .

Folks just don't know how to stake them ....I guess .

Sarge

Folks just don't know how to stake them ....I guess .

Sarge

The oil filter mount is a flat iron boss and a flat filter base. Very easy to seal.

Therefore it should have a pile of RTV applied to it. Maybe it will extrude enough into the passages to prevent the flow of oil through the filter. This will keep the filter from getting dirty, representing a good savings on maintenance.

View attachment 885044

View attachment 885045

I replaced my oil pan gasket a few months ago and found quite a few BB sized chunks of orange RTV in the bottom. Too bad they wouldn't quite fit through the screen on the oil pickup so they could block oil flow and keep my oil passages nice and clean.

Maybe better to get another 2f to rebuild, by time you bore this block or reline would it have another rebuild left in it?

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

- Thread starter

- #79

This block will clean with a 1.5mm overbore.

As a bonus, displacement increases form 4.2L to 4.4L, and CR goes from 7.8 to 8.2 with no other change.

As a bonus, displacement increases form 4.2L to 4.4L, and CR goes from 7.8 to 8.2 with no other change.

FishTacos

Full Globetard

So an overbore does bump up CR that significantly. I was trying to wrap my head around that the other day and gave up.....either because it runs well with my 1mm overbore or, more probably, because my head was not big enough to wrap around that concept. This must have a more profound effect on a closed chamber head, right?

Edit: Cylinder head, that is.....

Edit: Cylinder head, that is.....

Last edited:

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)