DanS HJ-45

SILVER Star

- Thread starter

- #541

How did you get your axles powdercoated? you obviously didn't stuff em in your oven, did you use heaters or bring 'em to a shop?

The axles and frame are not powdercoated. Just painted (with POR15). All of the parts that bolt to them are powdercoated (like the axle knuckles and things). I'm not a fan of powdercoating axles and frames, because it means you can't ever really weld to them again. I don't weld cast metal anyhow, so it's no big loss (also, I figure the baking relieves some internal stress in many cast parts).

I have to get up at 5:30 tomorrow to go to work, but....

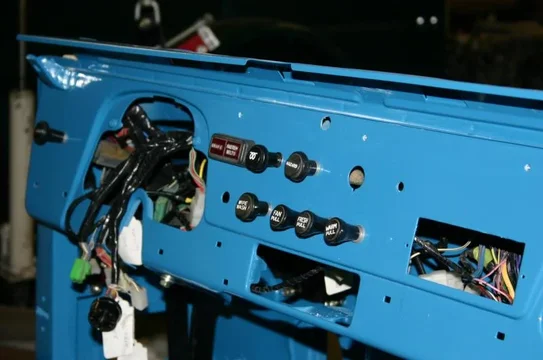

Thanks to Alia176, beno, Bad Mojo, and sl33p3 we got it on. I'll let the pictures do the talking. Thanks guys!

Dan