DanS HJ-45

SILVER Star

- Thread starter

- #301

Then I cut the holes out for the gauges themselves...

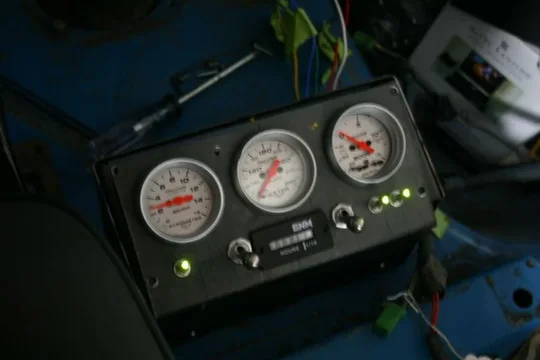

And because the holes were there I was obviously obligated to put the gauges themselves into the panel...

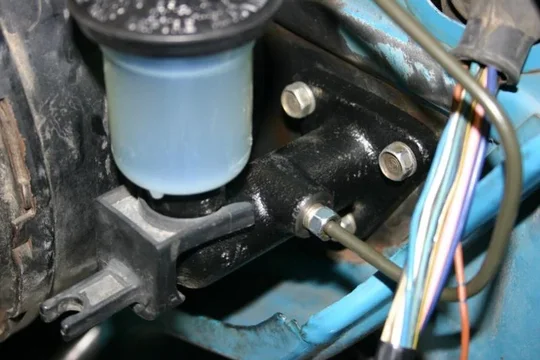

I then started on the box that hold this fancy pants panel. Our of 16GA, I bent a 3 sided box (slightly angled from front to back). Added to this I bent some tabs and spot welded them onto the three sided box to act as the flange for the panel to mount. You'll notice that in this picture that the cuts are ugly, which isn't just because they'll be under a panel--I just eyeballed the first set of cuts...

And because the holes were there I was obviously obligated to put the gauges themselves into the panel...

I then started on the box that hold this fancy pants panel. Our of 16GA, I bent a 3 sided box (slightly angled from front to back). Added to this I bent some tabs and spot welded them onto the three sided box to act as the flange for the panel to mount. You'll notice that in this picture that the cuts are ugly, which isn't just because they'll be under a panel--I just eyeballed the first set of cuts...