DanS HJ-45

SILVER Star

- Thread starter

- #221

Dan,

Is that Donaldson from the FPG series? I've been lookin at them online and when I called the local distributer I forgot to ask if the elbows rotate on the models with the elbow. I assume they do - would you happen to know?

They do indeed rotate.

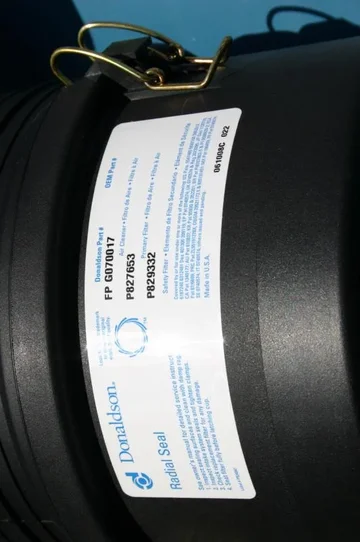

It is an FPG. Since the inlet to the turbo is 3 inches, I just bought the FPG with a 3 inch outlet so that I didn't have to adapt between different sizes. A smaller filter would fit better, and certainly flow MORE than enough air but since it fits....

That's the part number for that one. IIRC, it's just the last two numbers that indicate the outlet (straight or elbow).

They are plastic, but they aren't in the least bit cheap. Actually, the metal band seems lighter than the plastic FPG filter.

Dan