- Joined

- Jul 22, 2012

- Threads

- 583

- Messages

- 16,381

- Location

- Winter Park, Florida

- Website

- www.cruisermatts.com

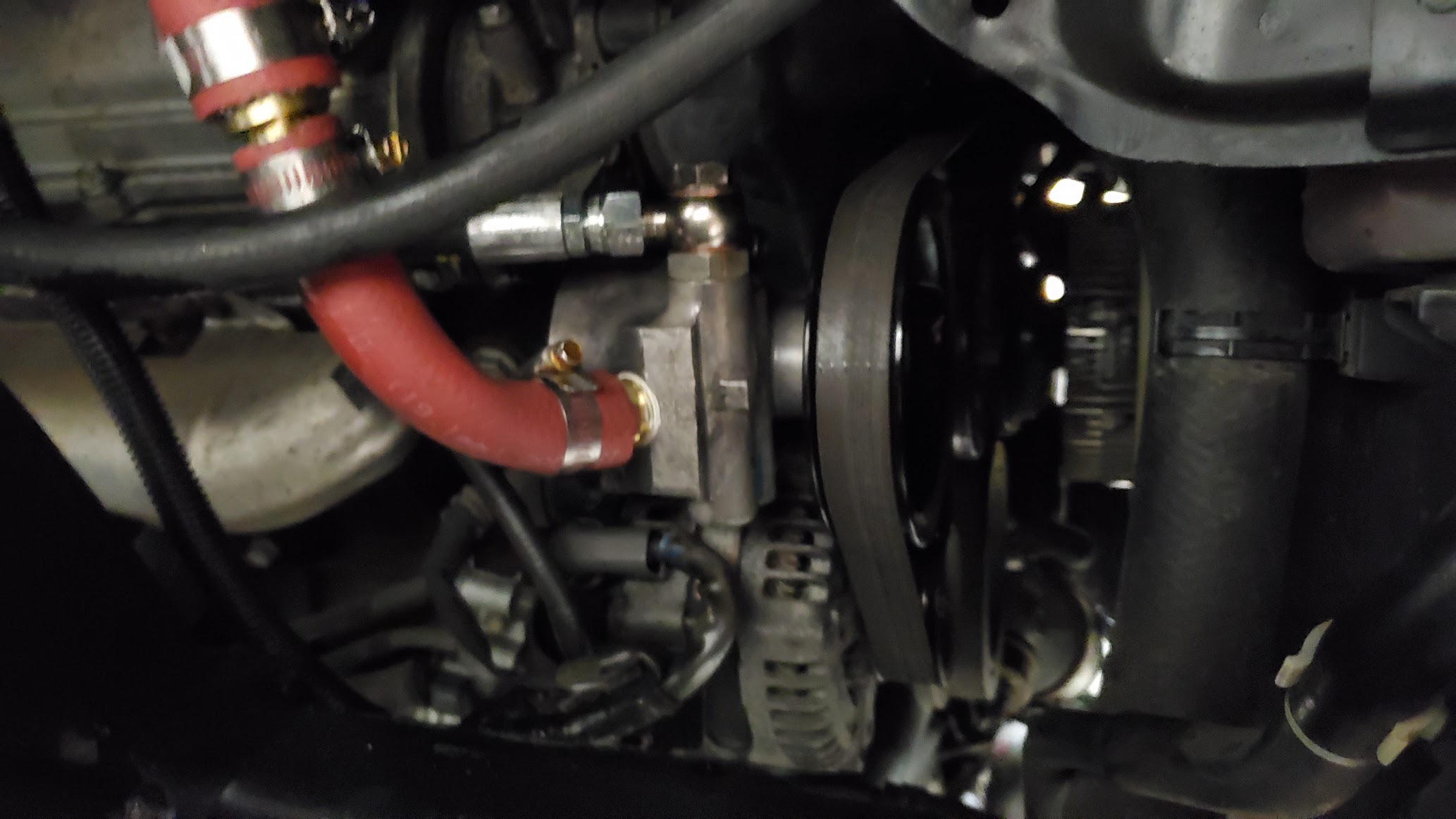

We would need a 5" or potentially smaller pulley...

I'm gonna get iterative on this. Tomorrow I'll run the stock pulley with my 'i lost the orifice fitting' mod, which if my understanding is correct will make the pump noisy but boosty at higher rpms. It should still suck at idle.

Then maybe we drill the cbr pump. I can put it in my drill press since we are making a through-hole, but what part number gives me a 5" or smaller pulley? Since you ordered 10...

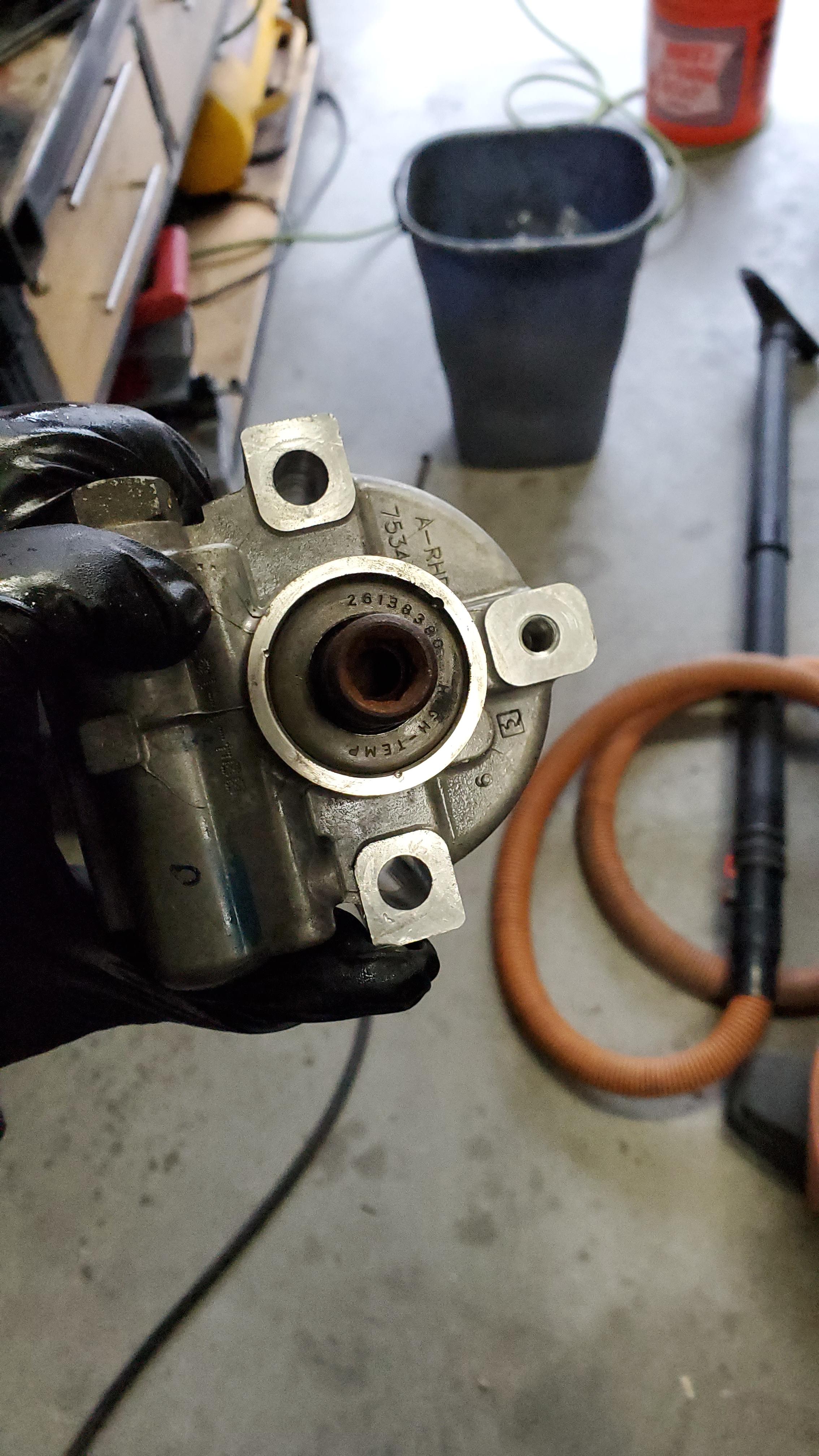

we'll see, i have the diameters for each part number but they all look like they have different offsets from the pictures. There was no info about that. Measure the distance from the back of your pump to the pulley once it's assembled.

You just want a Sierra pump don't you? Is this a trick to fence your eBay Camaro pump?

lol I'm no con man, I have faith in the eBay pump