If they are good, it's worth it... Especially if they are matching up everything and testing everything as opposed to just tanking and boring the block.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Excessively underpowered 1HZ + poor fuel economy

- Thread starter Leitrum3

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?DanS HJ-45

SILVER Star

your comment made me think of this:

Johnny Cash

"If you're gonna play the game, boy, you better learn to play it right."

"You got to know when to hold 'em; know when to fold 'em.

"Know when to walk away; know when to run.

kinda fits working in the shop ...

Only one problem with that: That's not Johnny Cash. Kenny Rogers sang "The Gambler."

But the man in black did sing about drilling it out so that it would fit, and with a little bit of help from an A-dapt-a kit....

Carry on. I like what I see in the rebuilt kit. Definitely time to take a break any time you get frustrated. Seems to work just about every time.

And the paint marker is a very good tip.

Dan

crushers

post ho

my bad

old school story tellers ...

Only one problem with that: That's not Johnny Cash. Kenny Rogers sang "The Gambler."

But the man in black did sing about drilling it out so that it would fit, and with a little bit of help from an A-dapt-a kit....

Carry on. I like what I see in the rebuilt kit. Definitely time to take a break any time you get frustrated. Seems to work just about every time.

And the paint marker is a very good tip.

Dan

Ha! I noticed that too. Kenny Rogers was my first big concert as a kid.

- Thread starter

- #125

Only one problem with that: That's not Johnny Cash. Kenny Rogers sang "The Gambler."

Heh, I wasn't going to say anything.

- Thread starter

- #126

Something has been nagging at me ever since I dropped all the new parts off at the machinists last week. When I showed him the new conrods, he asked me why I had bought them, and then proceeded to show his irritation at this by lecturing me about how I had probably screwed myself. His take on it was, because of the ceramic coating, and maybe because the bushes come pre-installed, he had no way of making any adjustments to the piston protrusion if it was off. I know I'm far from the first person to make this upgrade, so what has been done before? Isn't this situation part of the reason Engine Australia automatically sends the #5 head gasket?

I have a feeling I'm going to get a call sometime in the next week about this, I'm hoping somebody out there has a solution!

I have a feeling I'm going to get a call sometime in the next week about this, I'm hoping somebody out there has a solution!

Even when doing a head gasket on one of these trucks it's always recommended to run the thickest stock head gasket.

It may be worth your time to get everything balanced while your in there. You are essentially building a bulletproof 1hz.

It may be worth your time to get everything balanced while your in there. You are essentially building a bulletproof 1hz.

- Thread starter

- #128

Not a lot of progress lately, I'm mostly just waiting on the machine shop at this point. We had a "snow storm" last week that pretty much shut the city down for several days so that set things back a bit, or so I'm told by the shop. Coming from Alaska, it's still pretty amusing that 6" of snow over two days could shut a major city down for something like 5 days.

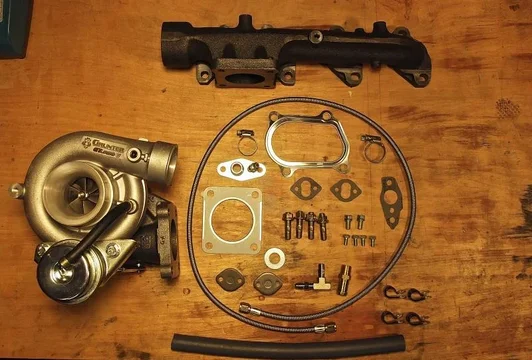

Anyways, I've kept busy cleaning parts I'll reuse and ordering all of the miscellaneous bolts, belts and water piping that didn't come in the rebuild kit that I need to replace to baseline (and for the bulletproof factor). A big shout out to Akella for helping me navigate the process and track down part numbers for everything. I also received my turbo kit from Graeme last week. If anyone was wondering about a more specific parts list he includes in his kits, this is what it looks like.

If anyone was wondering about a more specific parts list he includes in his kits, this is what it looks like.

Since I'm new to the turbo world, can anyone verify if I can use the standard turbo outlet elbow that's used for the 1HD-T? It's one of the only parts I haven't ordered because I thought it might come with Graeme's kit for some reason. I did manage to track down the thread below discussing some alternatives to the Toyota part-- has there been any further thought on this by anyone? I should mention that I'm keeping what I can of my current (2 1/2"? I can't remember...) exhaust system since it's practically new and I need to give the bank account some recovery time (rebuild kit + turbo + machining + misc parts = ).

).

https://forum.ih8mud.com/diesel-tech-24-volts-systems/745083-another-1hdt-gets-3-exhaust.html

Anyways, I've kept busy cleaning parts I'll reuse and ordering all of the miscellaneous bolts, belts and water piping that didn't come in the rebuild kit that I need to replace to baseline (and for the bulletproof factor). A big shout out to Akella for helping me navigate the process and track down part numbers for everything. I also received my turbo kit from Graeme last week.

Since I'm new to the turbo world, can anyone verify if I can use the standard turbo outlet elbow that's used for the 1HD-T? It's one of the only parts I haven't ordered because I thought it might come with Graeme's kit for some reason. I did manage to track down the thread below discussing some alternatives to the Toyota part-- has there been any further thought on this by anyone? I should mention that I'm keeping what I can of my current (2 1/2"? I can't remember...) exhaust system since it's practically new and I need to give the bank account some recovery time (rebuild kit + turbo + machining + misc parts =

https://forum.ih8mud.com/diesel-tech-24-volts-systems/745083-another-1hdt-gets-3-exhaust.html

- Thread starter

- #129

Even when doing a head gasket on one of these trucks it's always recommended to run the thickest stock head gasket.

It may be worth your time to get everything balanced while your in there. You are essentially building a bulletproof 1hz.

Also, in response to my own question, I learned that Engine Australia is also willing to provide decked pistons with the ceramic coating if I find that the piston protrusion doesn't meet spec. They even offered to send new ones and take the old ones back in exchange, there's just the matter of shipping. So that's a partial solution, if it comes down to it. More information and options is always better than less, even if the timing sucks.

I've used my standard outlet for the turbo (from a 1HDT originally) and have no problems with cooling or spooling up a grunter 2 on a 1HDFT engine. A 3 inch exhaust would be nice, but I do not view it as essential at this time.

cheers,

jan

cheers,

jan

- Thread starter

- #131

I've used my standard outlet for the turbo (from a 1HDT originally) and have no problems with cooling or spooling up a grunter 2 on a 1HDFT engine. A 3 inch exhaust would be nice, but I do not view it as essential at this time.

cheers,

jan

Thanks Jan, I'll keep moving forward and assume I'll just need to grab one of these at some point soon. My understanding of 3 inch is similar, maybe necessary if I was trying to intercool and extract the most out of this engine, but that's not the case here. I've also heard anecdotal stories that going that big on the HZ can also work against you depending on your setup by providing too much flow. Don't hold me to that though, the internet is vast and only 10% of it is accurate at best...

- Thread starter

- #132

Well, I feel somewhat vindicated today given the title and start of this thread. After dropping off my fuel pump and injectors at DFIS PDX on Monday, I got a call from them this afternoon. They had broken everything down for inspection and discovered that the inside of the pump was filled with rust, old wvo sludge, and the cam lobes had significant pitting (I've heard of this before and Mark guessed that it is attributed to the acidity of the wvo). I found this example of the same issues, though not a Toyota.

I'm going to call them back tomorrow morning and ask them to take some photos of what they've found and to retain the old parts so I can see what kind of shape it was in myself. Ultimately though, I'm just pleased to know that it's no surprise I was getting terrible mileage and was underpowered, even for a 1HZ. The injectors were also in sorry shape, but single stage are easy to fix so they're getting rebuilt as well.

Imagine my girlfriend's confusion when I was excitedly telling her about the terrible things they found. My response to her was, "If you think about it, mine was in such bad shape, it can only get better from here!"

I'm going to call them back tomorrow morning and ask them to take some photos of what they've found and to retain the old parts so I can see what kind of shape it was in myself. Ultimately though, I'm just pleased to know that it's no surprise I was getting terrible mileage and was underpowered, even for a 1HZ. The injectors were also in sorry shape, but single stage are easy to fix so they're getting rebuilt as well.

Imagine my girlfriend's confusion when I was excitedly telling her about the terrible things they found. My response to her was, "If you think about it, mine was in such bad shape, it can only get better from here!"

Just to be sure, isn't the acidity and rust from wvo that hasn't been cleaned enough to remove enough water? I plan on running wvo in an HZ and heard this comes from not removing enough of the water...

- Thread starter

- #134

Just to be sure, isn't the acidity and rust from wvo that hasn't been cleaned enough to remove enough water? I plan on running wvo in an HZ and heard this comes from not removing enough of the water...

From what I've researched, poorly de-watered wvo is definitely the culprit regarding the rust. I feel like I've heard contradictory stories on the pitting so I can't really comment on that. Either way, this is all related to whatever the PO did wrong since I've never run wvo/svo in mine. I do run b100 and b50 depending on the time of year, but it's commercially processed so I don't really worry about this sort of thing. Running b100 is also one of the reasons I'm putting money into an IDI and not a DI.

crushers

post ho

B/C

don't do it. you hear all the great things about WVO but most don't want to talk about the expensive ooops that come with it.

it isn't free

it is a lot of work

it is messy and makes your vehicle stink

if you forget to purge and the temps drop you are SOL or worse yet spending money on repairs.

i have watched many cruiserheads get on the WVO wagon and VERY few keep using it. it is one of those fads that sound great but in reality ... suck.

your truck, your time, do as you please. just thought i would play the Devil here.

sorry for the tangent.

don't do it. you hear all the great things about WVO but most don't want to talk about the expensive ooops that come with it.

it isn't free

it is a lot of work

it is messy and makes your vehicle stink

if you forget to purge and the temps drop you are SOL or worse yet spending money on repairs.

i have watched many cruiserheads get on the WVO wagon and VERY few keep using it. it is one of those fads that sound great but in reality ... suck.

your truck, your time, do as you please. just thought i would play the Devil here.

sorry for the tangent.

- Thread starter

- #136

B/C

don't do it. you hear all the great things about WVO but most don't want to talk about the expensive ooops that come with it.

it isn't free

it is a lot of work

it is messy and makes your vehicle stink

if you forget to purge and the temps drop you are SOL or worse yet spending money on repairs.

i have watched many cruiserheads get on the WVO wagon and VERY few keep using it. it is one of those fads that sound great but in reality ... suck.

your truck, your time, do as you please. just thought i would play the Devil here.

sorry for the tangent.

I'm with Wayne on this one. If you're going to go to great pains to process WVO, I would take it a step further and make biodiesel out of it instead. It just doesn't seem worth the risk for how much we all love our trucks.

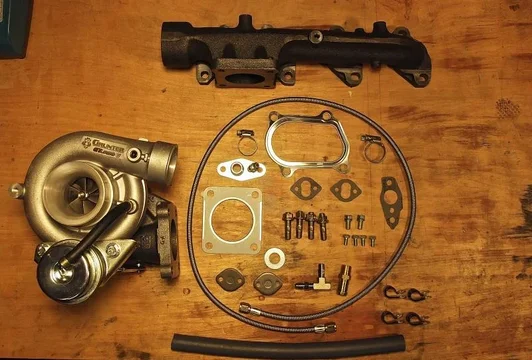

If you want to see what bad quality WVO does to the inside of a 1HZ pump, take a look at the images I asked the shop to send me this morning of what they'd found!

Not such a pretty sight. I'm still amazed considering the shape of things that they are only charging me around $700 for the total rebuild.

Not such a pretty sight. I'm still amazed considering the shape of things that they are only charging me around $700 for the total rebuild.

crushers

post ho

nasty

I am so glad I ruled out the WVO thing. Gross

From what I've researched, poorly de-watered wvo is definitely the culprit regarding the rust. I feel like I've heard contradictory stories on the pitting so I can't really comment on that. Either way, this is all related to whatever the PO did wrong since I've never run wvo/svo in mine. I do run b100 and b50 depending on the time of year, but it's commercially processed so I don't really worry about this sort of thing. Running b100 is also one of the reasons I'm putting money into an IDI and not a DI.

DI engines should have no problem with 100% biodiesel (B100). Once it's processed from WVO/SVO etc to biodiesel the compounds that cause problems are destroyed.

Was enough money saved through WVO to pay for the IP rebuild?

- Thread starter

- #140

DI engines should have no problem with 100% biodiesel (B100). Once it's processed from WVO/SVO etc to biodiesel the compounds that cause problems are destroyed.

Was enough money saved through WVO to pay for the IP rebuild?

I've read a couple of white papers that lean away from DI for long term B100 use, but that doesn't mean DI isn't just fine to use it and just because someone wrote it and had it published doesn't make it right. Regardless, it's a very debatable issue and not one worth getting into here. Like I said, the reliability of IDI on B100 long term was only one of the reasons I've gone the route I have in this build.

As far as enough money saved, if you read the post you quoted, I stated that I've never run WVO in this truck and probably never will (unless there's an apocalypse or total societal breakdown and suddenly all the gas stations close!

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)