- Thread starter

- #201

Any idea what would happen if you changed the coupler to a 3.5" or 4" versus 3"?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Any idea what would happen if you changed the coupler to a 3.5" or 4" versus 3"?

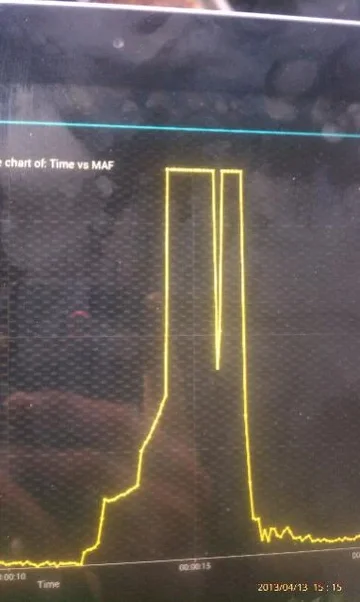

I don't know how that would help. I just tried a 3" MAF and had the exact same problem.

I know, but I just tried a 3" MAF in the post right before your first post and the results were nearly the same as the stock MAF. Some type of cut off and the MAF readings stopped at around 3500

Ok, then I misunderstood that the 21010 Toyota sensor was similar or the same as the oem 95-97 MAF.