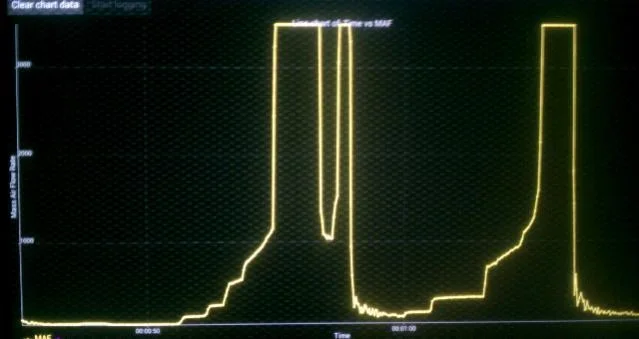

read the air flow through the OBDII port. I'm not sure how the URD is wired in so I can't say it's a factor. But on that Safari truck as soon as we installed my modded MAF were continued to read air flow all the way up through to red line on a truck set to 10psi.

from memory the stock MAF would saturate at around 23lbs while we pushed my MAF to 36lbs.

from memory the stock MAF would saturate at around 23lbs while we pushed my MAF to 36lbs.