- Joined

- Oct 22, 2002

- Threads

- 170

- Messages

- 5,386

- Location

- Durango, Colorado

- Website

- www.durangomagazine.com

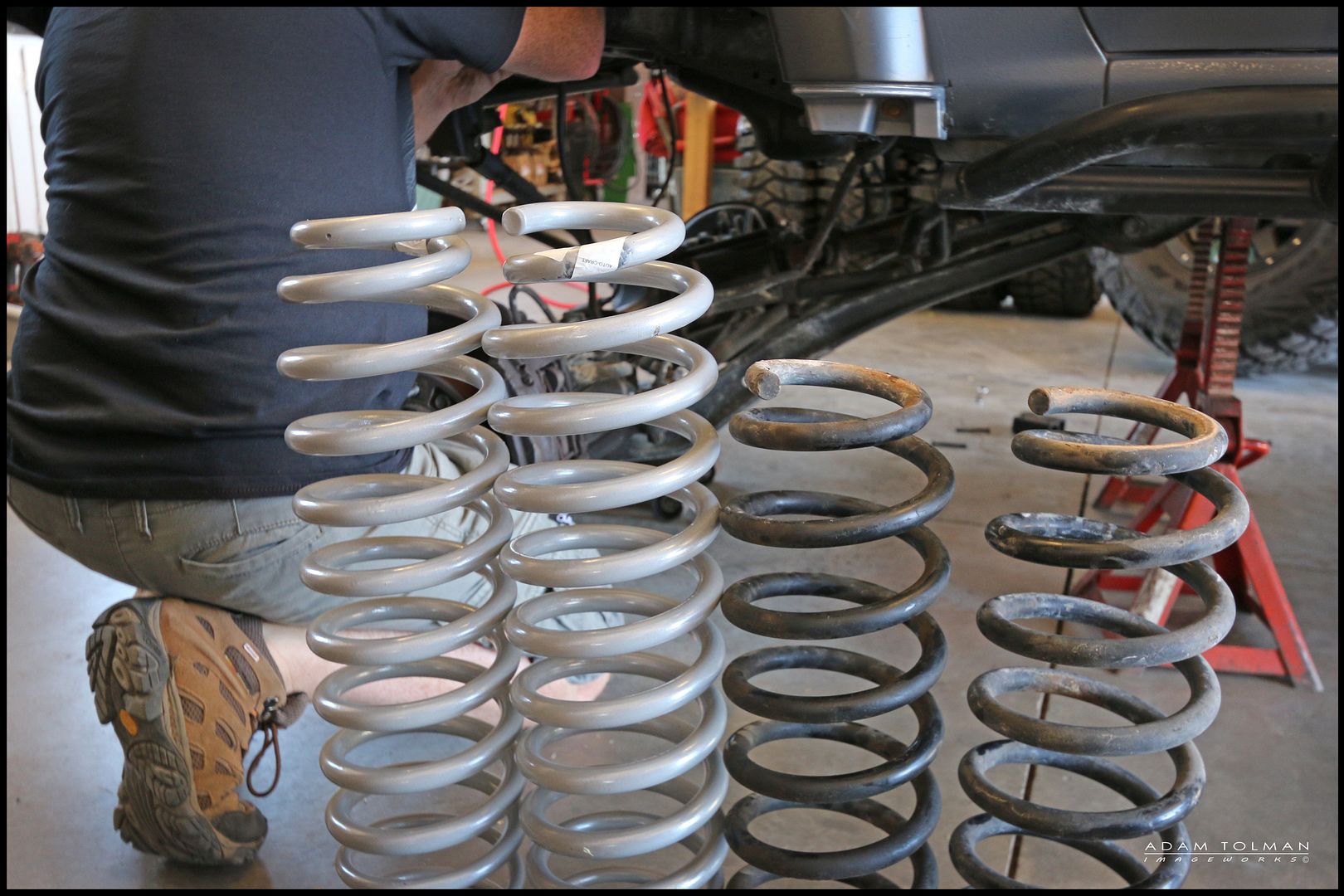

Comparison picture of 3 rear springs. Slee 4” heavy, Ironman TOY025C "medium", and OEM.

Kind of cool to see the material difference between them. I wish I would have weighed them all at the time. The Slee easily felt twice as heavy as the Ironman.

Kind of cool to see the material difference between them. I wish I would have weighed them all at the time. The Slee easily felt twice as heavy as the Ironman.

Last edited: