Over the last couple weeks I have been executing my winter maintenance and started my winter build plans.. maintenance items completed:

Parts being installed now:

- new TPS

- replaced inner and outer front bearings, regreased

- greased prop shafts, rear Upper and lower Control arms, panhard rod

- rebuild starter

- cleaned alternator

- replaced fuel tank primary fuel filter

- removed all carpets, cleaned and dried

- wire loomed all exposed wiring under carpets (running to aux fuse panel and dual amps/sub)

- greased BIOR rear bumper spindles, pull pins with copper based anti seize

- removed skid plates and cleaned mud/debris from undercarriage

- removed rear speed sensor, DS side - was throwing a code.. cleaned it, put it back in, still throwing code.. new sensor on order

- cleaned throttle body

- cleaned all fuse boxes under the hood from swamp sludge (100 went swimming last month)

- cleaned all electrical connections, sealed with dielectric

- replaced two seized pullies - tensioner idler and one ordinary idler (it seized and blew my serpentine apart)

- new serpentine belt

- removed rear cargo system for repainting/rubberizing

Parts being installed now:

- front and ear TJM pro lockers

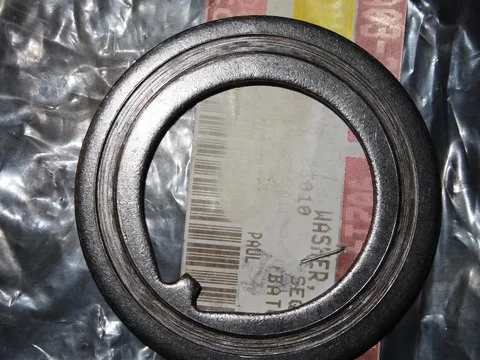

- master install kits

- Slee UCA's

- fix pesky rear right speed sensor

- rebuild rear end

- clean seatbelts

- repaint and touch up sliders/skids/bumpers

- install front and rear lockers

- install slee UCA's

- alignment

Last edited: