I got my exhaust rerouted for around $200. You could try something like that, for the time being.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Official 1HD-T/FT Fuel Pump Mod Tuning Thread

- Thread starter ForealBoreal

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?I can't go over 3K without EGT's climbing past 1300, and quick. The idea that my timing is retarded and I am venting still burning fuel makes a lot of sense to me.

I had a similar thing with my spare engine, same specs to yours except 3 inch exhaust and safari cooler. egts would start to climb rapidly once you got near 3 grand, but below 2600ish i could hold it flat and it wouldnt see more than 550-600 degrees c (pre turbo). I thought exactly the same thing and i did ask the bloke who did the injector pump for the new engine and he said it is possible that at revs the supply pump is not making enough pressure to advance the timing enough, but he said if its old and worn then the timing spring would be worn as well which would allow the timing to be advanced with less pressure, but short of testing everything on a bench we wouldn't know, since then new engine is in with a gturbo and new injector pump and i haven't found a hill that is steep enough it will let me hold it flat without accelerating up haha

I had a similar thing with my spare engine, same specs to yours except 3 inch exhaust and safari cooler. egts would start to climb rapidly once you got near 3 grand, but below 2600ish i could hold it flat and it wouldnt see more than 550-600 degrees c (pre turbo). I thought exactly the same thing and i did ask the bloke who did the injector pump for the new engine and he said it is possible that at revs the supply pump is not making enough pressure to advance the timing enough, but he said if its old and worn then the timing spring would be worn as well which would allow the timing to be advanced with less pressure, but short of testing everything on a bench we wouldn't know, since then new engine is in with a gturbo and new injector pump and i haven't found a hill that is steep enough it will let me hold it flat without accelerating up haha

Thanks for the info. My pump is all original (I assume) but shouldn't be too worn out with only 120k on it.

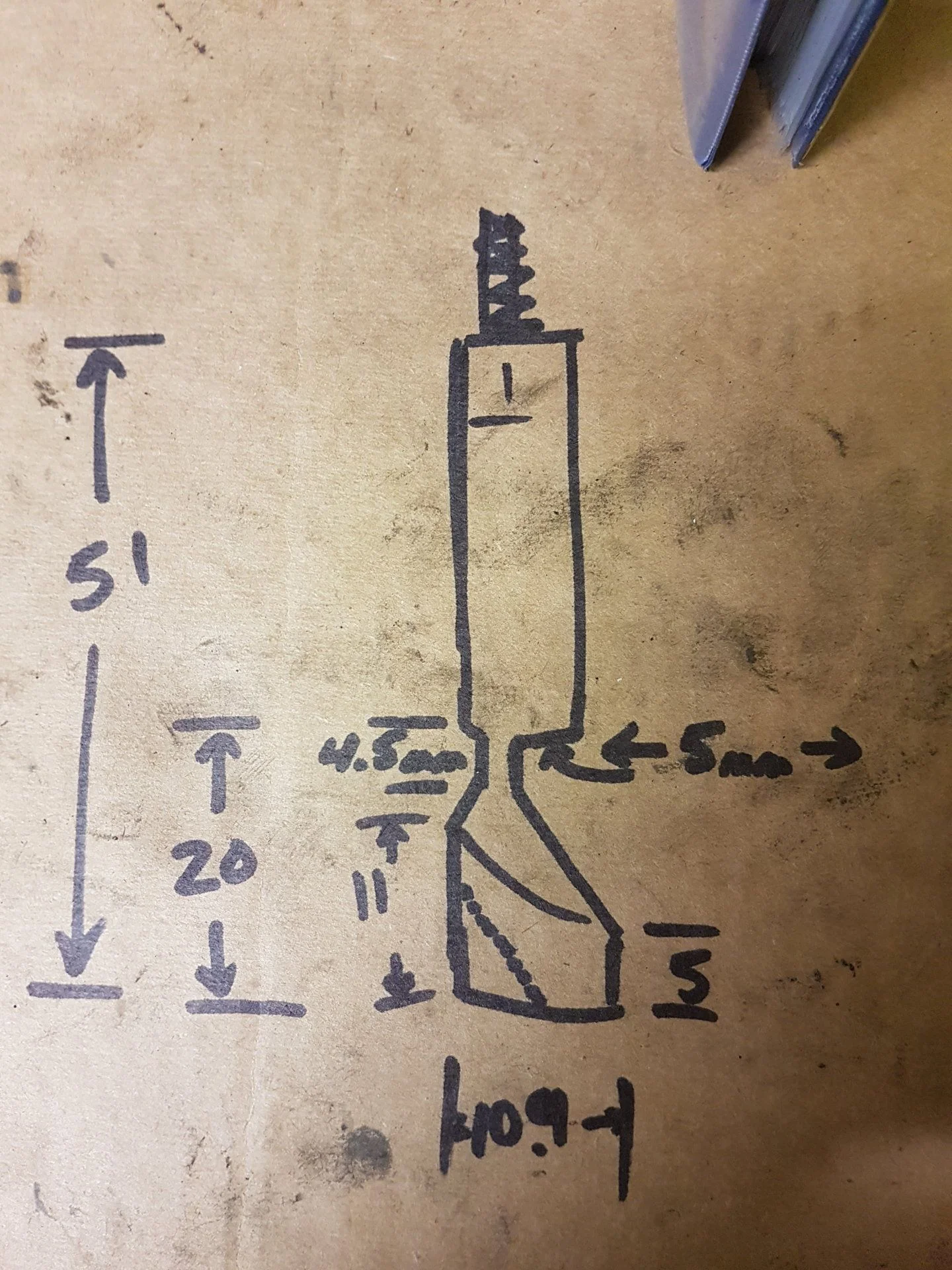

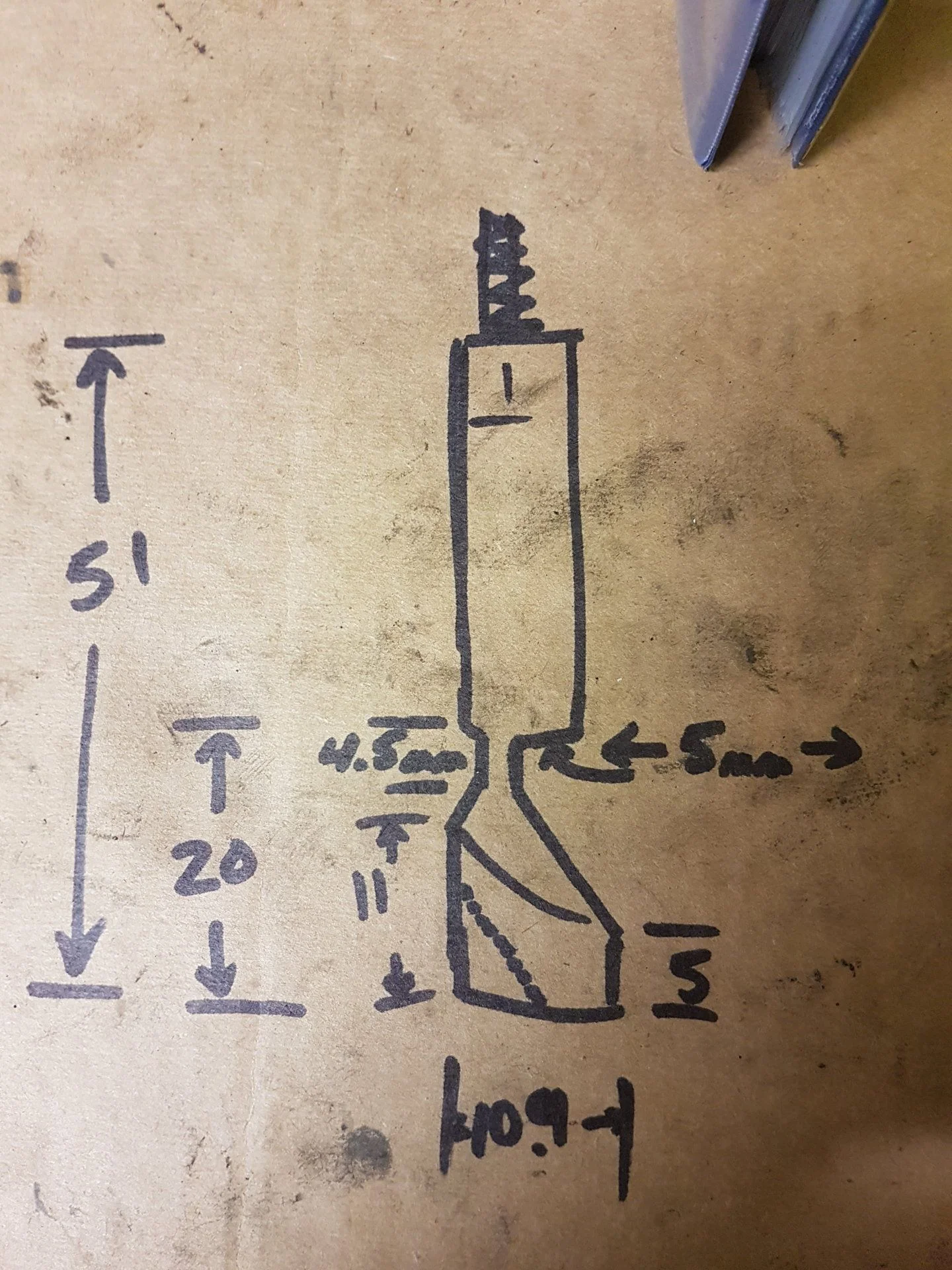

I will chime in later with more information, but I thought this might be found to be interesting. This is the pin that was in my 1995 JDM import with a HDFT.

I will chime in later with more information, but I thought this might be found to be interesting. This is the pin that was in my 1995 JDM import with a HDFT.

Well that pump has clearly been messed with previously. That's a deeper grind than either of the pins I've got, must be an aftermarket pin as opposed to an OEM pin that's been modified, as the concentric grind would be impossible to do by hand and have it turn out that nice.

Tapage

Club 4X4 Panamá

as the concentric grind would be impossible to do by hand

Ditto ..

Would be extremely nice to know where it came from ..

I too would really like to know where this pin came from… Perhaps I could source it here if I had some inkling of it’s originating location.

Dan

Dan

I will chime in later with more information, but I thought this might be found to be interesting. This is the pin that was in my 1995 JDM import with a HDFT.

Well all I know is that it came to me from Japan and it appears to have been anodized gold. I was told by some local guys that everything from Japan is anodized because they like things being flashy, even if its never seen. It's not an overly hard metal, as the groove in it seems to be fairly deep. At first I thought it might have been brass or something.

There are no identifying markings on it at all.

I like the fact that it has the slope cut into it already so reinsertion is simple. Compared to the other ones i saw in the shop, it seems that the taper on this is longer, to accommodate more boost without hitting over fuel.

I'll get some measurements on it in a bit and post them here.

Edit: look at this lousy drawing! Al dimensions are in mm.

There are no identifying markings on it at all.

I like the fact that it has the slope cut into it already so reinsertion is simple. Compared to the other ones i saw in the shop, it seems that the taper on this is longer, to accommodate more boost without hitting over fuel.

I'll get some measurements on it in a bit and post them here.

Edit: look at this lousy drawing! Al dimensions are in mm.

Last edited:

mudgudgeon

Resident galah

After market from somewhere. I'm sure there's pics of that pin floating about here in one of the "official HD-t/Gturbo/tuning etc" threads. I seem to remember possibly gturbo had a hand in it??

google might get a hit on it

google might get a hit on it

Drew these up on sketchup. comments and or suggestions please before I get onto working on the mill. TIA

Is it for 1hdt of ft pump. Output will be a lot different with the same pins because of the internal geometry of the pump. Finally get my hands of a spare ft pump and pulled it apart. Adjustability of this pump is a lot better than the 1hdt pump.

Is it for 1hdt of ft pump. Output will be a lot different with the same pins because of the internal geometry of the pump. Finally get my hands of a spare ft pump and pulled it apart. Adjustability of this pump is a lot better than the 1hdt pump.

Its for a 1HD-T pump

Will work. Much deeper than 4.5mm doenst have effect as the follower pin isn't any longer. Tuning will be a lot easier with the builtin hard stop. No messing around with shims etc. However i would prefer the stock ramp profile so the fuel tapers out on max boost. (if pump can deliver enough fuel though) .

Preface,

1. I have now fitted a full 3 inch exhaust, and installed a HPD front mount intercooler and seen no reduction in EGT's.

2 I have already theorized that my timing is retarded (or just not advancing as it should) giving me high EGT's especially at higher RPMS.

3. I haven't yet tested the timing as per the FSM, but it's the next thing to do on my list.

Yesterday I advanced my timing by a degree or so, and immediately felt more power through the entire range, even off-idle.

I went to my test hill, where I make passes at 95 KPH in 4th and 3rd (auto) and my testing verified my butt dyno results.

Where I would previously lose about 5 kph while running the hill in 4th, I can now accelerate from 95 - 100 over the length of the hill. EGT's are roughly the same.

I am going to turn my focus to getting the timing sorted out. I am starting with a new fuel filter, just to make sure that I don't have any restrictions on the feed side, because from what I understand if the lift pump is struggling, the timing won't advance properly.

Before I advanced the timing yesterday, it was at the factory timing mark. I do not plan on advancing it any more until I have the correct tools to measure it as per the FSM.

Does anyone have any other tips?

1. I have now fitted a full 3 inch exhaust, and installed a HPD front mount intercooler and seen no reduction in EGT's.

2 I have already theorized that my timing is retarded (or just not advancing as it should) giving me high EGT's especially at higher RPMS.

3. I haven't yet tested the timing as per the FSM, but it's the next thing to do on my list.

Yesterday I advanced my timing by a degree or so, and immediately felt more power through the entire range, even off-idle.

I went to my test hill, where I make passes at 95 KPH in 4th and 3rd (auto) and my testing verified my butt dyno results.

Where I would previously lose about 5 kph while running the hill in 4th, I can now accelerate from 95 - 100 over the length of the hill. EGT's are roughly the same.

I am going to turn my focus to getting the timing sorted out. I am starting with a new fuel filter, just to make sure that I don't have any restrictions on the feed side, because from what I understand if the lift pump is struggling, the timing won't advance properly.

Before I advanced the timing yesterday, it was at the factory timing mark. I do not plan on advancing it any more until I have the correct tools to measure it as per the FSM.

Does anyone have any other tips?

Tapage

Club 4X4 Panamá

make sure your boost compensator pin its not going further to the less fuel part of it when you are full boost ..

ok people im live in uruguay and me english is not the best , me land cruiser have not problems with egt and have good run but me work is diesel injection pumps repair , y reed all this forum and think many menbers have a very real look of the situation respect the numbers in the injectors the only change is the open pressure the second pressure in the old 1hdt is 190 bar a in the new is 145 bar all the hdt mount the same nozzle DLLA 150 P 77 in the old and the new , at this time i take a injection pump of a 2.4 turbo toyota and make a new push for the diaphragam of the turbo actuator in the pump i probe the modifiaction at the test bench and if you make the mark more of 4,5 mm the push dont work fine at this time i make another new push with modificated ramp only 4 mm they looks great the monday y put this in the 1hdt and make same probes i have pre turbo egt and have all the reads in me computer wait for the experience in me land cruiser

thanks to all the brillants minds

thanks to all the brillants minds

I turned up the main fuel screw 1/2 turn last night, 1/8 turn increments with a test drive in between each. It really woke things up! Less pedal required to accelerate normally, boost comes on stronger, much beefier midrange and top end power, the exhast tone improved, even the transmission seems to be in the right gear more of the time, no increased smoke, and EGT's appear to remain in check.

It's taken me a long time to reach this step, but the results have been very positive so far! I'll leave it here for a week or so and monitor the gauges, and make sure there's no negatives I just haven't noticed yet.

I do need to adjust the idle rpm down a little bit, it's now settled at about 800rpm with AC off, 1000 when AC cycles on, you need to have your foot firmly on the brakes when the rpm's jump.

It's taken me a long time to reach this step, but the results have been very positive so far! I'll leave it here for a week or so and monitor the gauges, and make sure there's no negatives I just haven't noticed yet.

I do need to adjust the idle rpm down a little bit, it's now settled at about 800rpm with AC off, 1000 when AC cycles on, you need to have your foot firmly on the brakes when the rpm's jump.

I turned up the main fuel screw 1/2 turn last night, 1/8 turn increments with a test drive in between each. It really woke things up! Less pedal required to accelerate normally, boost comes on stronger, much beefier midrange and top end power, the exhast tone improved, even the transmission seems to be in the right gear more of the time, no increased smoke, and EGT's appear to remain in check.

It's taken me a long time to reach this step, but the results have been very positive so far! I'll leave it here for a week or so and monitor the gauges, and make sure there's no negatives I just haven't noticed yet.

I do need to adjust the idle rpm down a little bit, it's now settled at about 800rpm with AC off, 1000 when AC cycles on, you need to have your foot firmly on the brakes when the rpm's jump.

Great results! For reference, I have my idle screw adjusted all the way out, and my fuel screw turned in until it is basically setting the idle. I can't adjust it up any more without raising the idle, then I "de-tuned" it back down to safe temps with the boost compensator.

Here is a pic of my latest tuning mod I did the 12" rotor and caliper upgrade which is one of the best things I have on the cruiser so far. Why am I posting about it in here you ask? Because my driving psi changed and it lowered my EGTs. Fair warning for anyone using EGTs to tune, if your brakes are old and your calipers are starting to freeze up it could be affecting your results

Well, finally dove head first into tuning using my Innovate LM-2 Wideband data monitor/logger. Decided to do so, as my rig has pretty much always been over-fueled at idle, and wanted to take care of that as winter makes it much worse...soot and smell. Power has been good, and no issues with MPG, returning 18-22 normally, with 16-18 towing a 3000 pound trailer. EGT's never above 1200, steady on climbs towing in the 950 to 1050 range depending on length of hill, weight of trailer. For those questioning, I am running the GTurbo Grunter Extreme with a 3" inside frame exhaust, and have a Safari Intercooler. SICS and BACS are both operational and tested. Air temps in lo-50s F, low humidity, 2500' altitude.

So, plugged everything in, with the O2 sensor about two feet downstream from the turbo.

To start with I warmed up and calibrated the sensor, and started the truck. As expected, when cold, things were still quite smelly and over fueled. Warmed the truck up and made a few observations.

Initial Observations - Wideband AFR readings are all over the place. When first started up, AFR was in the 10's. Once warmed up, runs at 20.9 which is same as if the sensor is out of the truck. Blip the throttle, and get black smoke and as low as 5 AFR. Downhill light throttle, AFR bounces from 20 to 100+; never under 20 as no load. Uphill on throttle, can go from 5 to 50, all depending on load and throttle. Never really settles on a figure, unless going steady up a long hill, where it would settle in the 40's, with 20psi boost, and EGTs running maybe 850; easily pulling 65 mph.

So, other than the rich at idle, it looks like I am lean under mid-throttle/hi boost.

Step 1 - Raise the star wheel / spring tension on the boost compensator. I knew this was my likely suspect for the low rpm over fueling, thus raised it one revolution. This brought the pin higher, thus fuel lower at lower rpm. Had confirmed that not getting down to the lowest part of the ramp at no boost (had a thin layer of grease on the pin for reference). Want it to start on the 45 degree toe portion of the picture below. Also backed off the smoke screw/ramp to allow the pin to be at it's highest point.

Step 2 - Confirm fuel pin on deepest profile, and that my H-L "index" the diaphragm is right . My pin is an aftermarket, and has a decent profile. Wanted to start at the high fueling, then be able to lean out across the boost profile as needed with the twist of the fuel pin.

Step 3 - Add fuel to Main Screw. After multiple runs, I ended up with 2.5 turns in from where I started to get the AFR's into the 20's on the uphill high-gear runs. According to the -FT manual this added 7.5cc of fuel to each injection cycle. Had to lower the idle after that as I was at 1500 rpm and on auto-pilot, LOL. No smoke when under throttle, and heaps more power. Also had to adjust the manual boost controller, as was then spiking up to 30psi if I got too much into the skinny pedal. EGT's still kept in check with the intercooler, highest seen was 1100.

if I got too much into the skinny pedal. EGT's still kept in check with the intercooler, highest seen was 1100.

Observations For Now - In the end, have the AFR 18.5 at idle, and low to mid 20's under load and boost, with EGT still in the safe-zone. Spent at least five hours tweaking the pump, 50 miles of spirited test driving, burned a bunch of fuel. Overall pretty happy if I can lose the idle smoke, get more power and not completely mess up my MPG or break anything. Will need to do a bit more driving to see if there are any issues with smoke, power, consumption, or EGT spikes.

Future Mod Tuning Question - @SeaJay was running the following boost cover. Wondering if it makes sense to get something like this, or to replace the Denso "cam" with a traditional screw/lock as found in other Bosch style pumps. I am thinking this may be the path to get more boost pin movement, ensuring that my idle fueling is trimmed and I can get to the max fueling of the pin.

Edit - anyone have a lead on a Zexel style cover which would work on the 1HD-FT pump? @Antony used one of these earlier in the thread.

So, plugged everything in, with the O2 sensor about two feet downstream from the turbo.

To start with I warmed up and calibrated the sensor, and started the truck. As expected, when cold, things were still quite smelly and over fueled. Warmed the truck up and made a few observations.

Initial Observations - Wideband AFR readings are all over the place. When first started up, AFR was in the 10's. Once warmed up, runs at 20.9 which is same as if the sensor is out of the truck. Blip the throttle, and get black smoke and as low as 5 AFR. Downhill light throttle, AFR bounces from 20 to 100+; never under 20 as no load. Uphill on throttle, can go from 5 to 50, all depending on load and throttle. Never really settles on a figure, unless going steady up a long hill, where it would settle in the 40's, with 20psi boost, and EGTs running maybe 850; easily pulling 65 mph.

So, other than the rich at idle, it looks like I am lean under mid-throttle/hi boost.

Step 1 - Raise the star wheel / spring tension on the boost compensator. I knew this was my likely suspect for the low rpm over fueling, thus raised it one revolution. This brought the pin higher, thus fuel lower at lower rpm. Had confirmed that not getting down to the lowest part of the ramp at no boost (had a thin layer of grease on the pin for reference). Want it to start on the 45 degree toe portion of the picture below. Also backed off the smoke screw/ramp to allow the pin to be at it's highest point.

Step 2 - Confirm fuel pin on deepest profile, and that my H-L "index" the diaphragm is right . My pin is an aftermarket, and has a decent profile. Wanted to start at the high fueling, then be able to lean out across the boost profile as needed with the twist of the fuel pin.

Step 3 - Add fuel to Main Screw. After multiple runs, I ended up with 2.5 turns in from where I started to get the AFR's into the 20's on the uphill high-gear runs. According to the -FT manual this added 7.5cc of fuel to each injection cycle. Had to lower the idle after that as I was at 1500 rpm and on auto-pilot, LOL. No smoke when under throttle, and heaps more power. Also had to adjust the manual boost controller, as was then spiking up to 30psi

Observations For Now - In the end, have the AFR 18.5 at idle, and low to mid 20's under load and boost, with EGT still in the safe-zone. Spent at least five hours tweaking the pump, 50 miles of spirited test driving, burned a bunch of fuel. Overall pretty happy if I can lose the idle smoke, get more power and not completely mess up my MPG or break anything. Will need to do a bit more driving to see if there are any issues with smoke, power, consumption, or EGT spikes.

Future Mod Tuning Question - @SeaJay was running the following boost cover. Wondering if it makes sense to get something like this, or to replace the Denso "cam" with a traditional screw/lock as found in other Bosch style pumps. I am thinking this may be the path to get more boost pin movement, ensuring that my idle fueling is trimmed and I can get to the max fueling of the pin.

Edit - anyone have a lead on a Zexel style cover which would work on the 1HD-FT pump? @Antony used one of these earlier in the thread.

Last edited:

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)