How are you planning to plug the extra ports on the fuel tank?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Stevo's 6BT60 Build Thread (1 Viewer)

- Thread starter StevoJonesFJ60

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #282

Congrats! You worked hard to get there. Glad to see it paying off. Very nice job.

Is that Stevo in the video?

Its been a lot of work but its been fun.

Yep that's me.

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #283

How are you planning to plug the extra ports on the fuel tank?

I was either going to cap them off, or just have them welded up.

Tapage

Club 4X4 Panamá

damn .. that sounds nice .. standard IP timing .. it sounds aggressive ..

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #285

**** .. that sounds nice .. standard IP timing .. it sounds aggressive ..

Yep standard timing. I will probably bump it slightly once I get some seat time. Prior to pulling the motor it was making close to 25 PSI boost, I want to get that number up to around 30-35 PSI.

The timing spacer bumps the timing at the upper RPM range though. I'm not sure how much.

I absolutely love the way that motor sounds.

that's the way VE pump equipped 6bt's sound normally.mine starts the same...barely turns over once and she's running.from what i understand, the timing spacer is supposed to advance timing in the upper rpm range by approx 10 degrees over stock.

i suggest leaving timing at stock settings...the best part of a ve is the lower timing at idle,which helps low end torque and responsiveness rather a lot.this makes the ve engines better tow motors (imop) than a p-pump equippped engine.all you need now is a 366 spring and it'll fly.

with the spacer you get the best of both...excellent bottom end and more agressive timing at higher rpm's.widens the torque curve nicely compared to a p-pump engine.if i was keeping my dodge i'd order one up for sure.kudo's on the build...it's gonna be sharp...

i suggest leaving timing at stock settings...the best part of a ve is the lower timing at idle,which helps low end torque and responsiveness rather a lot.this makes the ve engines better tow motors (imop) than a p-pump equippped engine.all you need now is a 366 spring and it'll fly.

with the spacer you get the best of both...excellent bottom end and more agressive timing at higher rpm's.widens the torque curve nicely compared to a p-pump engine.if i was keeping my dodge i'd order one up for sure.kudo's on the build...it's gonna be sharp...

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #287

that's the way VE pump equipped 6bt's sound normally.mine starts the same...barely turns over once and she's running.from what i understand, the timing spacer is supposed to advance timing in the upper rpm range by approx 10 degrees over stock.

i suggest leaving timing at stock settings...the best part of a ve is the lower timing at idle,which helps low end torque and responsiveness rather a lot.this makes the ve engines better tow motors (imop) than a p-pump equippped engine.all you need now is a 366 spring and it'll fly.

with the spacer you get the best of both...excellent bottom end and more agressive timing at higher rpm's.widens the torque curve nicely compared to a p-pump engine.if i was keeping my dodge i'd order one up for sure.kudo's on the build...it's gonna be sharp...

Yeah, I had read that somewhere, I already have the 366 spring installed and have to say for $20 it is by far the best mod for the money.

Thanks for the compliments, I can't wait to put this motor to use.

Stevo, Congrats on a wicked sounding machine! I have been so engrossed in getting mine going that I hadn't checked the thread in several days.

I have been so engrossed in getting mine going that I hadn't checked the thread in several days.

I love the noise you have worked so hard to make. I hope to reply to you with a video this weekend. Keeping my fingers crossed.

Keep it up.

I have been so engrossed in getting mine going that I hadn't checked the thread in several days.

I have been so engrossed in getting mine going that I hadn't checked the thread in several days.I love the noise you have worked so hard to make. I hope to reply to you with a video this weekend. Keeping my fingers crossed.

Keep it up.

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #289

Stevo, Congrats on a wicked sounding machine!I have been so engrossed in getting mine going that I hadn't checked the thread in several days.

I love the noise you have worked so hard to make. I hope to reply to you with a video this weekend. Keeping my fingers crossed.

Keep it up.

I gotta say I love the sound, I turned the idle down a bit so it sounds just about perfect. I love how easy it is to adjust a mechanical diesel. I can pretty much adjust and tune the everything with a small screwdriver.

And in terms of updates, I have been going over the wiring and should be able to incorporate the motor into the stock wiring harness with minimal hassle.

The 6BT is literally a 3 wire motor and I love it. One 000 cable runs from the battery to the starter, a small wire runs to the fuel shutoff solenoid, and a sensor wire runs to the starter to activate it.

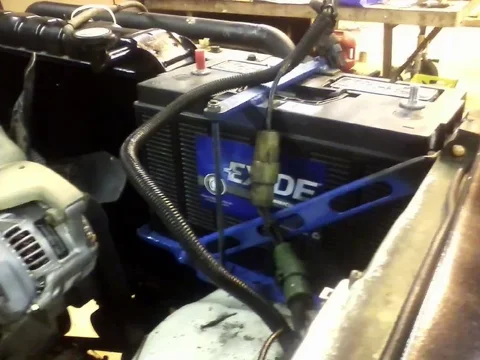

I have one battery installed in the stock location and plan on placing its compliment mirrored on the other side of the engine. I figure with both batteries providing 925 CCA each and them being wired in parallel supplies me with 1850 amps for starting the motor.

I also wanted to sit in the driver seat and see how it felt to shift through the gears. So I cut down the massive shifter on the clark transmission to a more reasonable and comfortable height.

I will probably make a custom shifter knob at work to enable me to more comfortably shift into reverse and first.

Also a buddy dropped off a 40" tire so I can get a pretty good visual of what the truck will look like as well as give me some input into the fender trimming that will be needed.

- Joined

- Jun 21, 2011

- Threads

- 233

- Messages

- 21,823

- Location

- Redding, California

- Website

- trail-tailor.com

Nice work Stevo.. The diesel sounds awesome. 40's are gonna rock on her..

J

J

Awesome to see it running! Man...I haven't even foot my 3FE together yet and I'm already dreaming of a diesel.

And in terms of updates, I have been going over the wiring and should be able to incorporate the motor into the stock wiring harness with minimal hassle.

The 6BT is literally a 3 wire motor and I love it. One 000 cable runs from the battery to the starter, a small wire runs to the fuel shutoff solenoid, and a sensor wire runs to the starter to activate it.

I have one battery installed in the stock location and plan on placing its compliment mirrored on the other side of the engine. I figure with both batteries providing 925 CCA each and them being wired in parallel supplies me with 1850 amps for starting the motor.

I also wanted to sit in the driver seat and see how it felt to shift through the gears. So I cut down the massive shifter on the clark transmission to a more reasonable and comfortable height.

I will probably make a custom shifter knob at work to enable me to more comfortably shift into reverse and first.

[/QUOTE]

I have ben working on the wiring too. I completely did away with the fuel solenoid wire and have a manual pull for fuel on and off. The rest of the wiring is super easy, I spent part of last night wiring the oil pressure, tach sensor (hope it works) and putting in a new stainless battery tray for battery No. 2. I really like the idea of having all those cranking amps available. Have you seen the guy that makes the stainless battery trays? They are a great deal in my opinion, cheaper than SOR stock ones! Stainless Steel Battery Trays for TOYOTA LANDCRUISER Shipping is usually supuer quick too.

The nv4500 shifter is pretty big too but I havn't modified it yet. I'm going to try to drive it a little before I figure out where I would really like it to be. I am supposed to pick up my radiator today and some intercooler tubing is suppoed to be here this afternoon as well. Let's see what happens over the weekend.

Did you have to crack a coulpe of injectors to bleed before first start or did it pull enough on it's own?

The 6BT is literally a 3 wire motor and I love it. One 000 cable runs from the battery to the starter, a small wire runs to the fuel shutoff solenoid, and a sensor wire runs to the starter to activate it.

I have one battery installed in the stock location and plan on placing its compliment mirrored on the other side of the engine. I figure with both batteries providing 925 CCA each and them being wired in parallel supplies me with 1850 amps for starting the motor.

I also wanted to sit in the driver seat and see how it felt to shift through the gears. So I cut down the massive shifter on the clark transmission to a more reasonable and comfortable height.

I will probably make a custom shifter knob at work to enable me to more comfortably shift into reverse and first.

[/QUOTE]

I have ben working on the wiring too. I completely did away with the fuel solenoid wire and have a manual pull for fuel on and off. The rest of the wiring is super easy, I spent part of last night wiring the oil pressure, tach sensor (hope it works) and putting in a new stainless battery tray for battery No. 2. I really like the idea of having all those cranking amps available. Have you seen the guy that makes the stainless battery trays? They are a great deal in my opinion, cheaper than SOR stock ones! Stainless Steel Battery Trays for TOYOTA LANDCRUISER Shipping is usually supuer quick too.

The nv4500 shifter is pretty big too but I havn't modified it yet. I'm going to try to drive it a little before I figure out where I would really like it to be. I am supposed to pick up my radiator today and some intercooler tubing is suppoed to be here this afternoon as well. Let's see what happens over the weekend.

Did you have to crack a coulpe of injectors to bleed before first start or did it pull enough on it's own?

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #293

I have ben working on the wiring too. I completely did away with the fuel solenoid wire and have a manual pull for fuel on and off. The rest of the wiring is super easy, I spent part of last night wiring the oil pressure, tach sensor (hope it works) and putting in a new stainless battery tray for battery No. 2. I really like the idea of having all those cranking amps available. Have you seen the guy that makes the stainless battery trays? They are a great deal in my opinion, cheaper than SOR stock ones! Stainless Steel Battery Trays for TOYOTA LANDCRUISER Shipping is usually supuer quick too.

Did you have to crack a coulpe of injectors to bleed before first start or did it pull enough on it's own?

I have seen those battery trays, they look well made and I really like them, however I have a hard time justifying an additional $70 on something when I could fab a basic one up for free, and a bit of time.

I cracked all of the injectors to bleed the air out of them. I had taken apart the injection pump a bit to do some mods to it so I wanted to make sure all of the air was bled out of them.

Hopefully your startup goes well.

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #294

I found an old video of me starting up the stock 6BT in the cummins.

MVI 1395 - YouTube

And here is some footage of me starting up the motor in the Cruiser.

MVI 2021 - YouTube

Got some time to slap a 40" tire on the dana 60 and I have to say I like the way that it looks.

I will probably end up getting some 43" Interco TSL SX tires.

So they will be taller but not as wide.

I am really liking my approach angle too.

I will definitely need to cut the front fenders a tad.

And plenty of room to turn the big tires as well.

MVI 1395 - YouTube

And here is some footage of me starting up the motor in the Cruiser.

MVI 2021 - YouTube

Got some time to slap a 40" tire on the dana 60 and I have to say I like the way that it looks.

I will probably end up getting some 43" Interco TSL SX tires.

So they will be taller but not as wide.

I am really liking my approach angle too.

I will definitely need to cut the front fenders a tad.

And plenty of room to turn the big tires as well.

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #295

Well I modified my np205 for twin sticking last night and have to say it turned into much more of a teardown then I had planned.

I found this thread on pirate and have to say the guy did a great job explaining the process.

How to: NP 205 twin stick CHEAP! - Pirate4x4.Com

There was a visible amount of wear on the shift rail I pulled out, fortunately I would be grinding that off anyway.

So what went wrong while I was working on it?

I accidentally let the shifter fork drop down, so I needed to pull one of the covers of the case. I was greeted by a needle bearing that decided to spill its guts out everywhere.

Then I let the tool i was using to try and lift it back up with slip into the case and I couldn't retrieve it from the cover I had pulled off.

So I ended up pulling off the rear output assembly and was greeted by two sets of needle bearings which decided to explode and fall everywhere.

I eventually got everything back together and installed the adjustable detent springs.

Thanks for the idea Brokenparts, they work great.

I found this thread on pirate and have to say the guy did a great job explaining the process.

How to: NP 205 twin stick CHEAP! - Pirate4x4.Com

There was a visible amount of wear on the shift rail I pulled out, fortunately I would be grinding that off anyway.

So what went wrong while I was working on it?

I accidentally let the shifter fork drop down, so I needed to pull one of the covers of the case. I was greeted by a needle bearing that decided to spill its guts out everywhere.

Then I let the tool i was using to try and lift it back up with slip into the case and I couldn't retrieve it from the cover I had pulled off.

So I ended up pulling off the rear output assembly and was greeted by two sets of needle bearings which decided to explode and fall everywhere.

I eventually got everything back together and installed the adjustable detent springs.

Thanks for the idea Brokenparts, they work great.

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #296

Looking good! I had a lot of the same problems with my split case. PO had taken it apart at some point and put some kind of silicone sealant everywhere, even on the nuts. One of my buddies has a good fat lip story to tell now about us getting it apart. Another simple job that turns into some kind of major affair. Just keep chugging away!

Speaking of major to small affair and back. I got my 6bt cranked yesterday. Ran great until I noticed a puddle of oil dripping out of the exhaust. Seal in the turbo. Now I have the turbo apart and I think it is an H1C. I looked up the rebuild kits thinking it was a 35 but those parts don't look like what I have. Do you know of a good link to find holset numbers and years? I know they were mixing the turbos up quite a bit from 93-95 during the changeover.

Seal in the turbo. Now I have the turbo apart and I think it is an H1C. I looked up the rebuild kits thinking it was a 35 but those parts don't look like what I have. Do you know of a good link to find holset numbers and years? I know they were mixing the turbos up quite a bit from 93-95 during the changeover.

Speaking of major to small affair and back. I got my 6bt cranked yesterday. Ran great until I noticed a puddle of oil dripping out of the exhaust.

Seal in the turbo. Now I have the turbo apart and I think it is an H1C. I looked up the rebuild kits thinking it was a 35 but those parts don't look like what I have. Do you know of a good link to find holset numbers and years? I know they were mixing the turbos up quite a bit from 93-95 during the changeover.

Seal in the turbo. Now I have the turbo apart and I think it is an H1C. I looked up the rebuild kits thinking it was a 35 but those parts don't look like what I have. Do you know of a good link to find holset numbers and years? I know they were mixing the turbos up quite a bit from 93-95 during the changeover.Think I found what i needed to know but this link can always be of help to find cummins stuff.

Tech Article Links - Dodge Cummins Diesel Forum

Tech Article Links - Dodge Cummins Diesel Forum

- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #300

Think I found what i needed to know but this link can always be of help to find cummins stuff.

Tech Article Links - Dodge Cummins Diesel Forum

That is some great information, thanks a bunch I will have to sit down and take some time to go through it all.

Also here is a pretty good site for information on propane injection:

http://www.mrsharkey.com/lpg.htm

Last edited:

Similar threads

- Replies

- 212

- Views

- 20K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)