The yellow top optima has rounded corners or are you thinking of something else. I built a custom tray for two red tops and made the corners round but may have been wise to have made them square so as to accommodate a different brand battery in the future..

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Skips FJ 35 BUILD

- Thread starter 47coeman

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?47coeman

Love those 45's

- Thread starter

- #462

KiefThe yellow top optima has rounded corners or are you thinking of something else. I built a custom tray for two red tops and made the corners round but may have been wise to have made them square so as to accommodate a different brand battery in the future..

I agree with you on the round to square, these tops were made for me and I will modify to accommodate changes you have recommended that is why I am doing the mock up with the wood model.

2fpower

SILVER Star

What an awesome build.

47coeman

Love those 45's

- Thread starter

- #464

2fpower

TNX for the kind words on this build. It is starting to come along nicely, it has been a bit of a long build but I have stepped it up a bit and hopefully get it done so I can enjoy it. The bed hold up is the inside wheel well and they should be done mid January that is the big hurdle to get over.

TNX for the kind words on this build. It is starting to come along nicely, it has been a bit of a long build but I have stepped it up a bit and hopefully get it done so I can enjoy it. The bed hold up is the inside wheel well and they should be done mid January that is the big hurdle to get over.

47coeman

Love those 45's

- Thread starter

- #465

Well the holiday’s are past so I thought I would get back in the groove to working in the shop, battery boxes were in the same place as I left them. I tore into them and started making the adjustments to make sure the yellow tops would fit into the spaces I have. Just a slow and go today more planning and trial and error. Tomorrow I should be able to get to a point where the light got bright at the end of the tunnel. Also today I set up the width of the bed so in a couple of weeks when the wheel wells are finished it will be a quick finish or at least that is how I see it. Pics tomorrow of the work that I have completed for everyone’s eyes. Also I got a call from the powder coater today stuff is ready for pickup, slow but sure.

Last edited:

47coeman

Love those 45's

- Thread starter

- #466

Moved forward with the battery box’s inching my way. The guy from up north called is behind with my wheel wells so I had to cancel my trip to pick up the parts. Changed gears and went and picked up some small stuff from the powder coater. Gave me an uplift in my spirits of at least getting something done.

awesome it is looking great congrats and good luck with the finish...

47coeman

Love those 45's

- Thread starter

- #468

Back on the 35, focused on the 45 and Ron has been inching along on the tub. From the last post above has not been much work on the 35. Time has come to move forward. Brent and I got after it yesterday and pretty much have all the rough in fitting and noted where the last bit of body work needs to be done before I weld the fender skins on. Tail gate reveals are good so all I need to finish is the fender wells so I can do the a last bit and call it good. Waiting for the wheel wells from a more experienced body man and weld her up taking my time so I doesn’t warp the big panels, then off to primer. powder coating.

The 35 is coming along great, I love all the attention to detail that you have put into it! I'm finally getting started on my 45-ish build using parts from two rusted 40 tubs. I really like your cab length. I remember you saying its 8" longer than a standard 45 cab. I don't have access to a real 45 to use a a reference point, so I was wondering if you could give me a measurement from the seam behind the door to the back of the cab? I would really appreciate it! Thanks...Ed.

Last edited:

47coeman

Love those 45's

- Thread starter

- #470

From the back edge of the B pillar is 14 1/2” which gives me the right amount of leg room as Iam 5’ 10” tall. In my 45 it is a bit pinched.The 35 is coming along great, I love all the attention to detail that you have put into it! I'm finally getting started on my 45-ish build using parts from two rusted 40 tubs. I really like your cab length. I remember you saying its 8" longer than a standard 45 cab. I don't have access to a real 45 to use a a reference point, so I was wondering if you could give me a measurement from the seam behind the door to the back of the cab? I would really appreciate it! Thanks...Ed.View attachment 2650733

Can you share how you fabbed the Fj60 PS box to the frame?Got my 60 box from West Texas Offroad and mounted today with new hardware, very good service and quick with sending it way south. Had it rebuilt and ported for hydraulic assist later. Was going to get the springs mounted and found out I will need to get some bushing machined from my friend Gerald a small job but while it is apart need to do it right. The 60 box looks good sitting there things are finally moving forward.View attachment 1675254

Thank you, that helps a lot!...I can't wait to see yours when it's completed!From the back edge of the B pillar is 14 1/2” which gives me the right amount of leg room as Iam 5’ 10” tall. In my 45 it is a bit pinched.

47coeman

Love those 45's

- Thread starter

- #473

It is done just like a Saginaw box see install in here for assembly, put spacers in the bolt holes so when you put the bolts through the frame it doesn’t crush the frame together. Match the bolt lay out to your box. It makes it easier if you have the axle mounted to align the pitman arm and that angle. Check in here might be an installation for your 60 box also in this section also, good luck.Can you share how you fabbed the Fj60 PS box to the frame?

47coeman

Love those 45's

- Thread starter

- #474

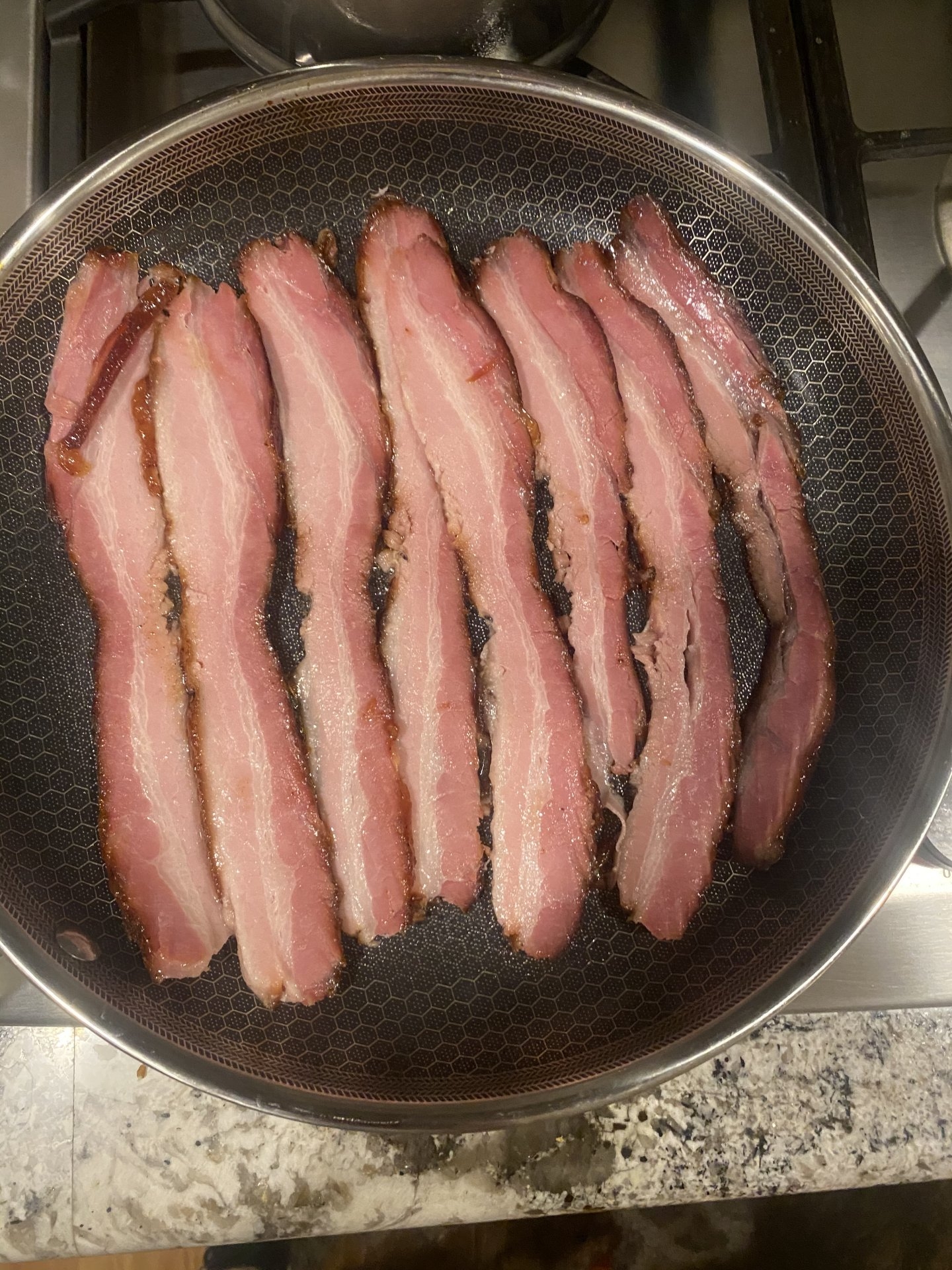

Off topic, This last week I have been working on the final assembly of the bed taking it up to getting ready to install the wheel wells that are coming from a very slow metal man. So Yesterday I smoked some pork bellies to turn into bacon, of course I cured them and smoked for 7 hours slow and cool at 165 degrees they turned out very tasty. Had some for breakfast today...

You just made my sausage look less than epic!

Looks really good and those welds Sweet!!!Been pretty quite for awhile still waiting on the fender wells. Switched to the trailer to utilize my time and will have picks soon of the construction.

Today I have pics of the gas tank I got in this week from Summit. Perfect fit like factory at 18 gal.

View attachment 2682000

View attachment 2682001

47coeman

Love those 45's

- Thread starter

- #479

Got the gas tank in well about 95% just need to do the last little bit on the straps top and bottom, put the bolts in and tighten them down relative an easy job. I8 gallon for a 96 S10 Chevy pickup 2 door. First pic is showing the 2x2 tubing bracket install. 2nd is the tank set in and checked for fit. 3 rd is the top straps in place not bolted in place

Similar threads

- Replies

- 212

- Views

- 20K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)