DSB345

SILVER Star

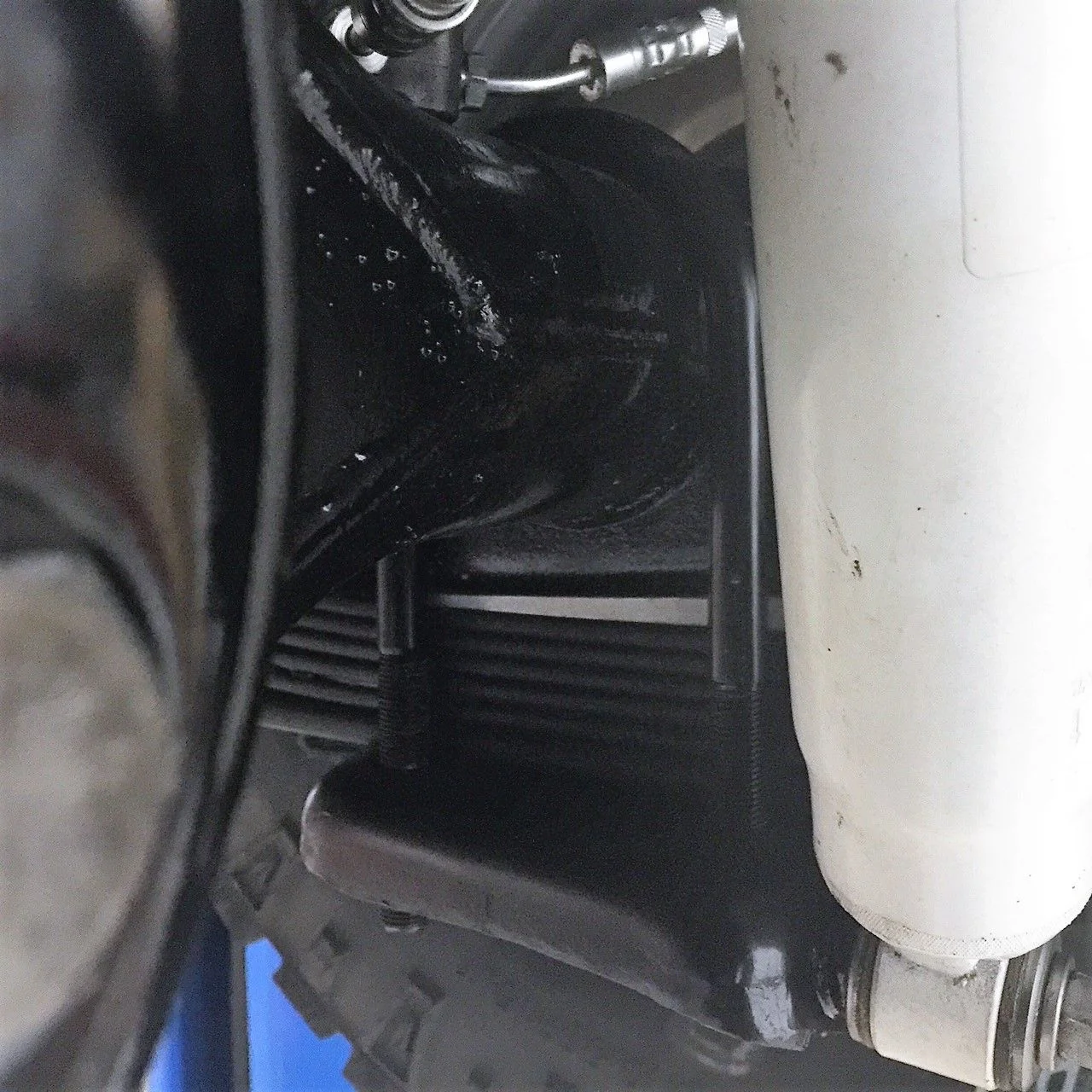

Mike, Your axle is already getting dirty

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Mike, Your axle is already getting dirty

IH8MUD!!!!

IH8MUD!!!!

How much is your truck lift to have that much of shim?Today I installed the rear spring shims to correct the drive line angles. Used 3* degree Belltech shims and I'm happy to report the drive line angles are once again pretty close to perfect.

Here are a few pics of before and after pics, used the exact same reference point for taking the before and after pics.

Before

After, sorry for the dark exposure

Before

After

Belltech shims

How much is your truck lift to have that much of shim?

Mike, Great visual explanation. I'm considering OME 2.5" lift in the future. Now I know. ThxGeorg @orangefj45 , thanks for your input.

Below is the 6 step sequence and calcs. followed to arrive at 3° shims.

Background: Installed Old Man Emu suspension springs and shackles with 2.5 inch lift

Cause: Experiencing Drive line vibration with an audible sound, vibration was speed sensitive

Note: Did not have this condition with old leaf springs

Goal: Minimize drive line vibration and audible noise and prevent premature U joints wear, and match drive line angles

I removed the drive shaft and used a magnetic angle finder to determine the drive line angles, while vehicle was flat and level on concrete floor slab.

Step 1 measure pinion angle

Pinion flange angle reading 81°

Step 2 measure E-brake drum angle

E-brake angle reading 84°

Step 3 calculate drive line misalignment

Sketch for clarity

(∴) 3° shims required in order to correct the drive line angle misalignment

Step 4 installation of 3° shims

Step 5 recheck drive line angles post correction method installation

Results: Pinion flange angle 84°, E-brake angle is static and unchanged

Step 6 Road test

Pending

~As far as the shim material is concerned I'm confident that what was used is of adequate strength and its longevity will not be compromised by normal driving conditions, on and off road.

Mike.

I'm not trying to hijack your thread. It's very evident that your methodical and do clean work. And I certainly appreciate that or I wouldn't chime in.

Georg @ Valley Hybrids