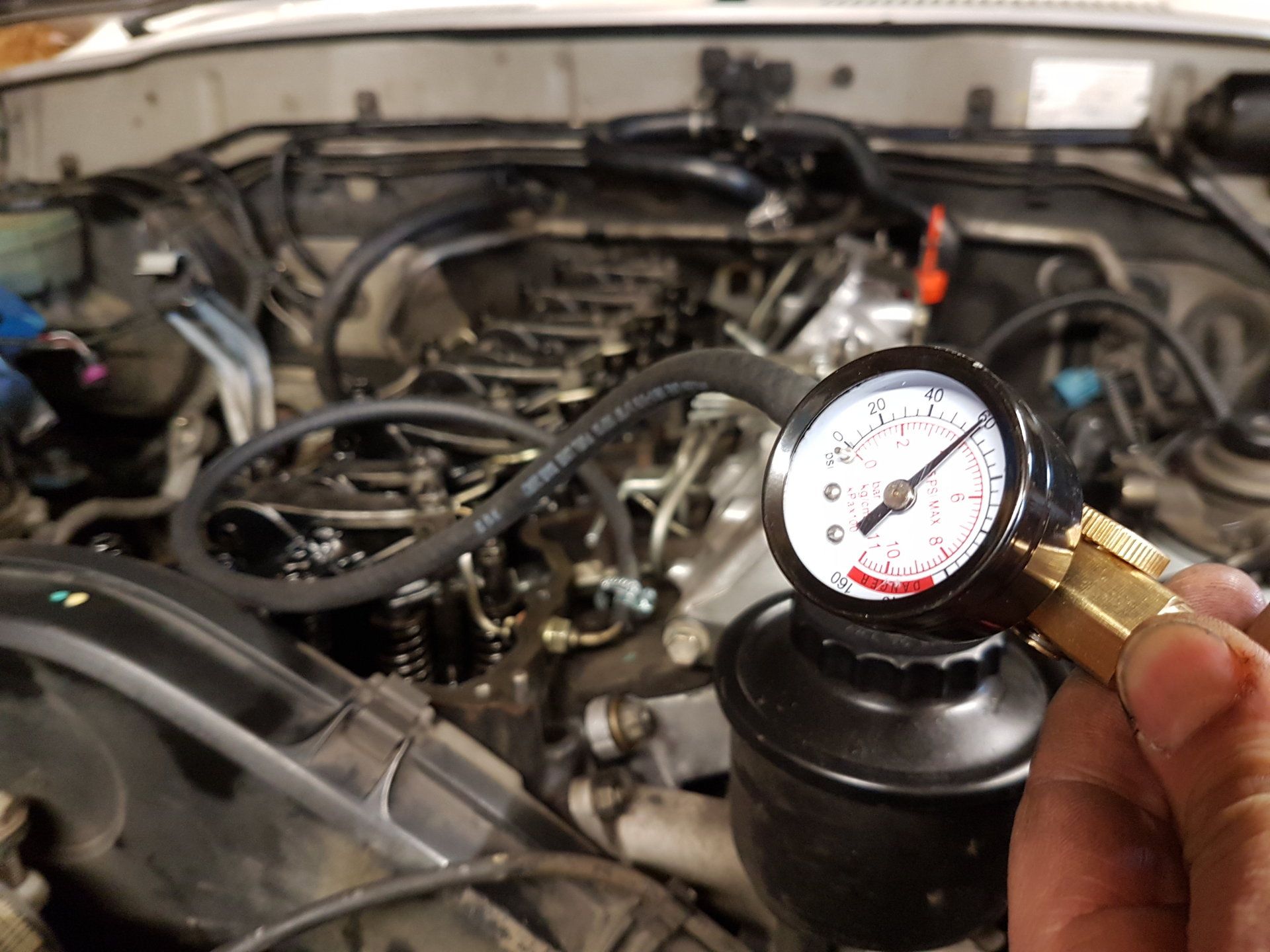

I was given a lovely gift from one of my machinist customers earlier today, and had a few moments with a 2 year old helper after supper to check the timing. Following the FSM seems quite straightforward, although I really can't see how this is doable with everything in place.

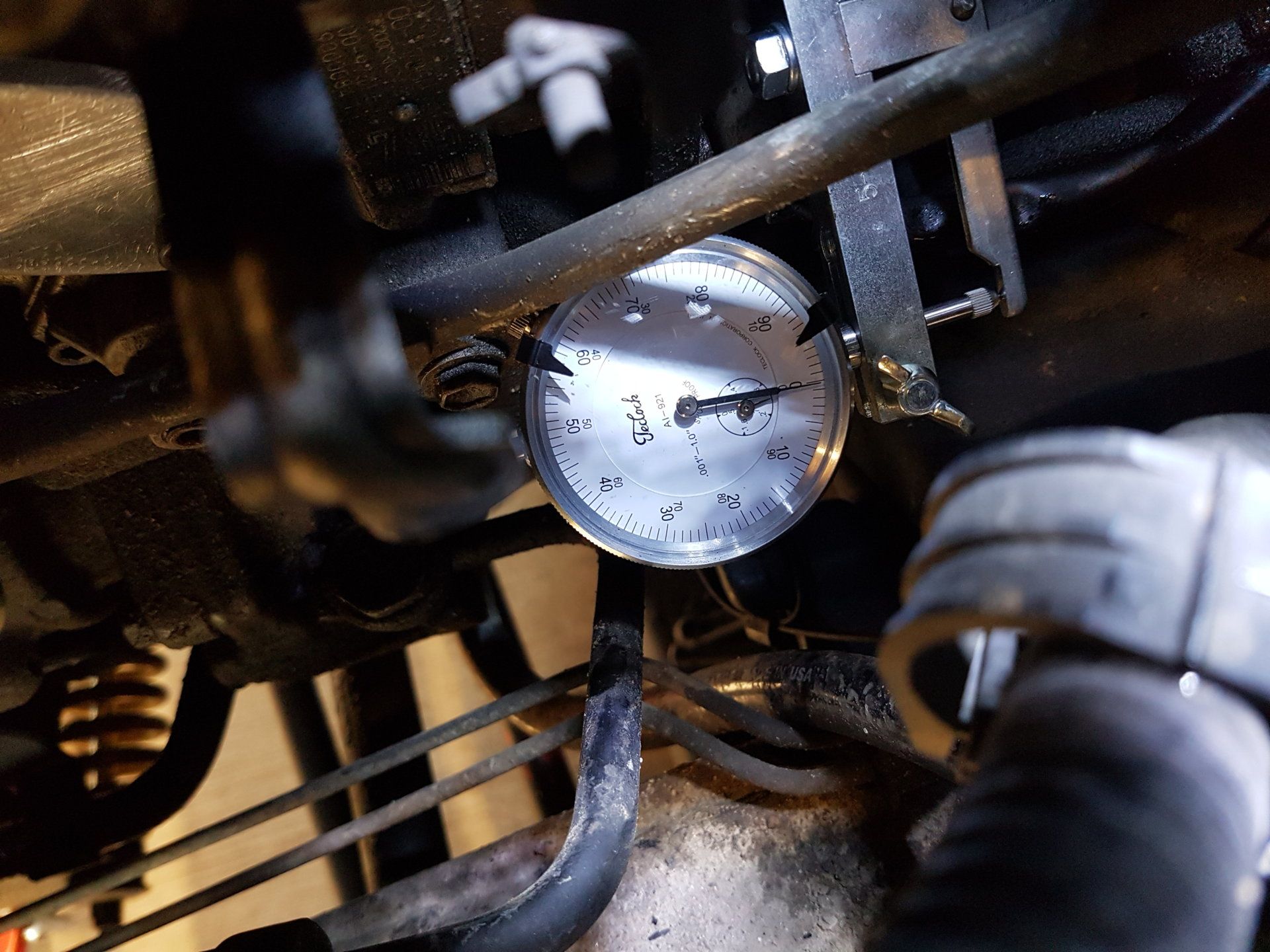

As it says, from tdc, rotate the crank ccw until no more movement of the needle happens. Then with help of my wife (the 2 year old was not a reliable source) make sure that moving the crank back and forth doesn't move the needle at all. Zero out the dial.

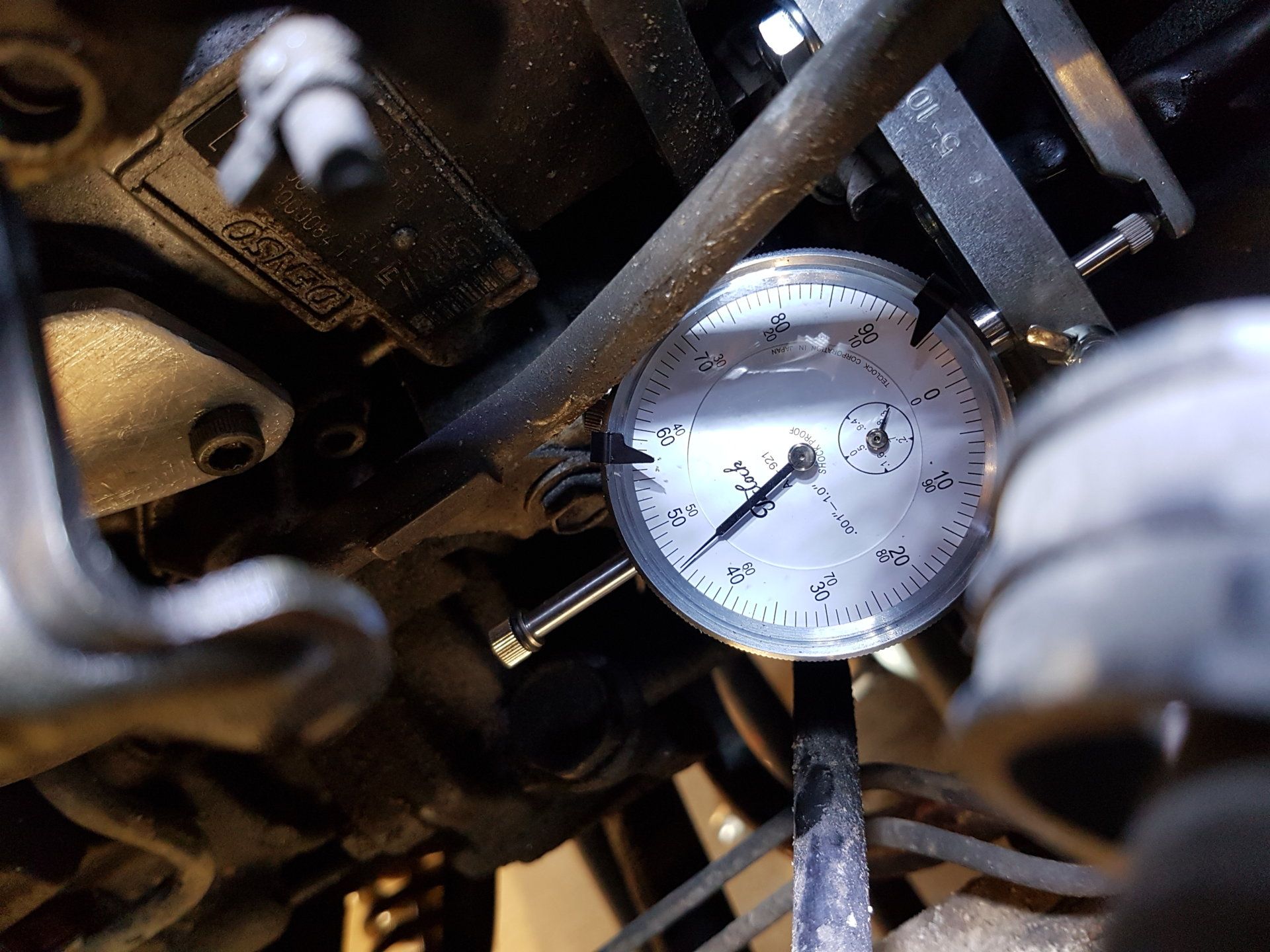

Then, rotated the crank back up to the indicator marks on the case and take a phone picture to ensure its as close to lined up as I could get it. Honestly, could this mark have been put in a more inconvenient location?

Then, had a looksee at my dial.

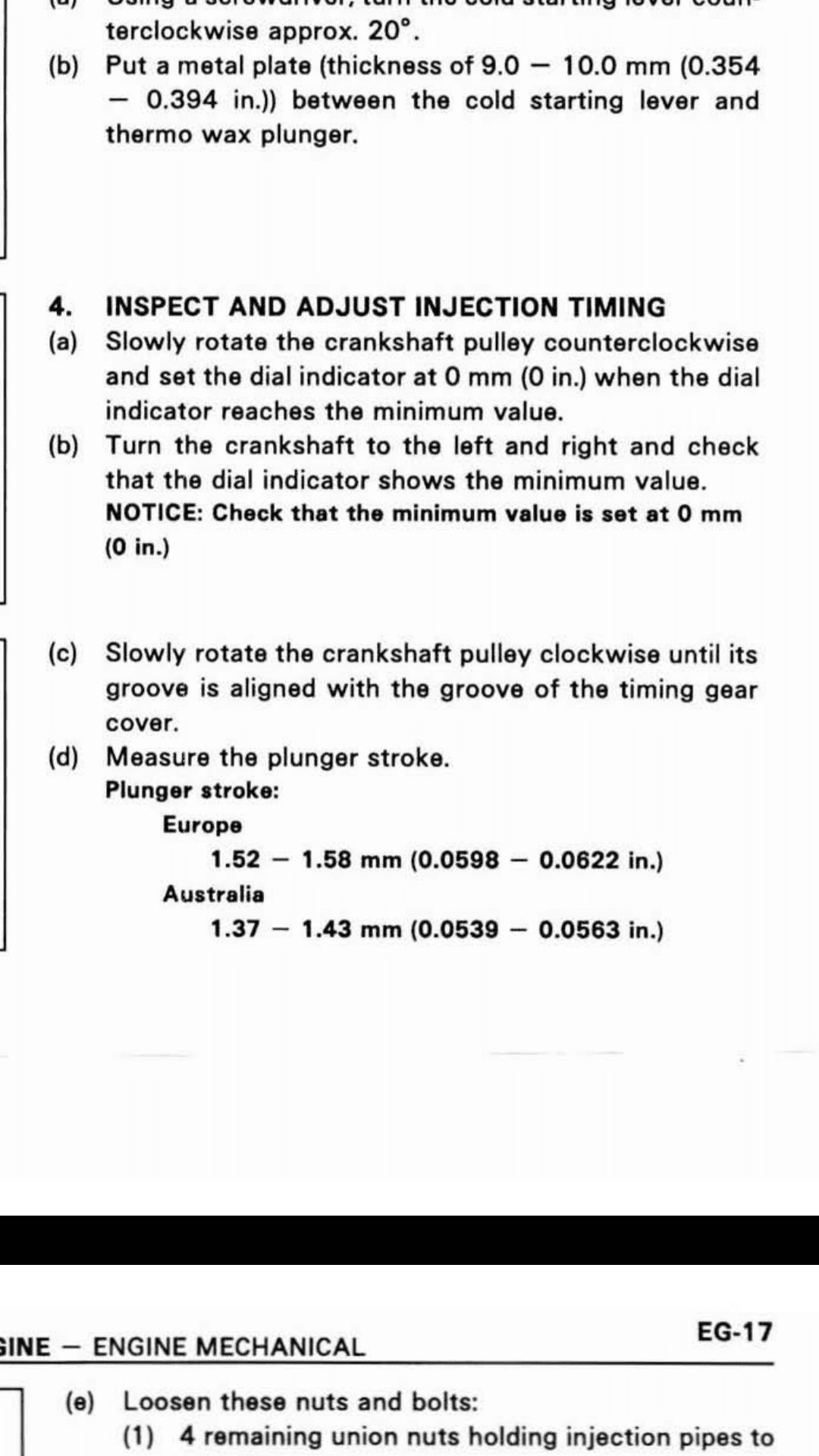

This being an imperial gauge, that should be about 0.045". Fsm has a different spec for Europe and Australia, with Europe being a bit more advanced, which I naturally assume is due to climate, and not prevalence of dangerous animals. I'm going to lean on the European numbers being in the north. Specs are here:

So, holy crap. This thing is around 20% retarded. The marks on the pump case are consistent with someone retarding the timing at some point. Some reading online says that would reduce nox emissions. This makes me believe that the Japanese PO may have had it adjusted as such in order to help pass emissions tests, or as part of the shakken inspections.

Right now its time to put the kiddos to bed, but I can work on adjusting it back later on. Then, everything can go back together.