- Thread starter

- #21

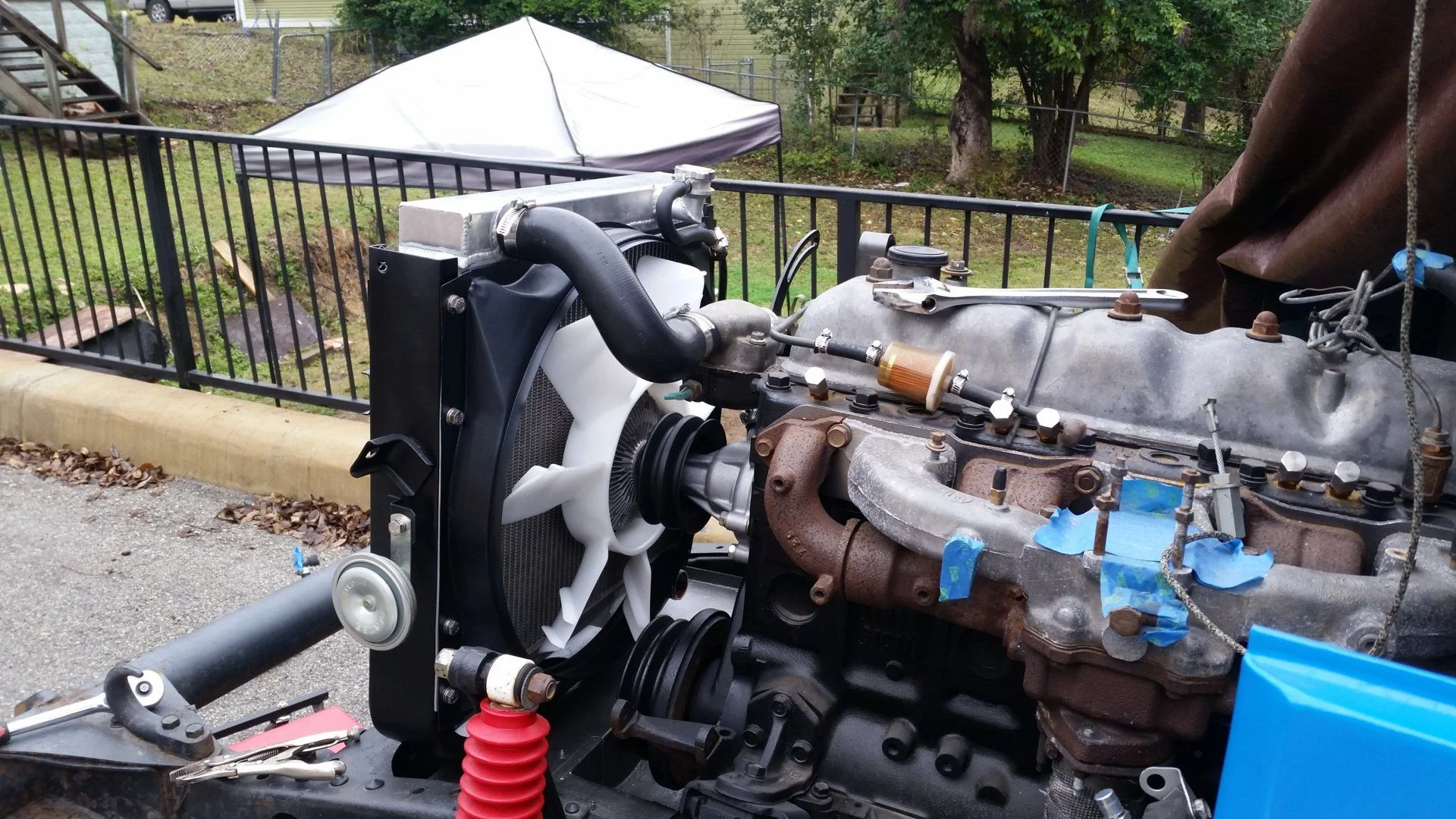

Getting ready to tow about 2 miles to paint shop..

These pop up cannopies represented my shop for over 2 years

Needed low-range and locker engaged for Tacoma to pull it up the hill out of the backyard

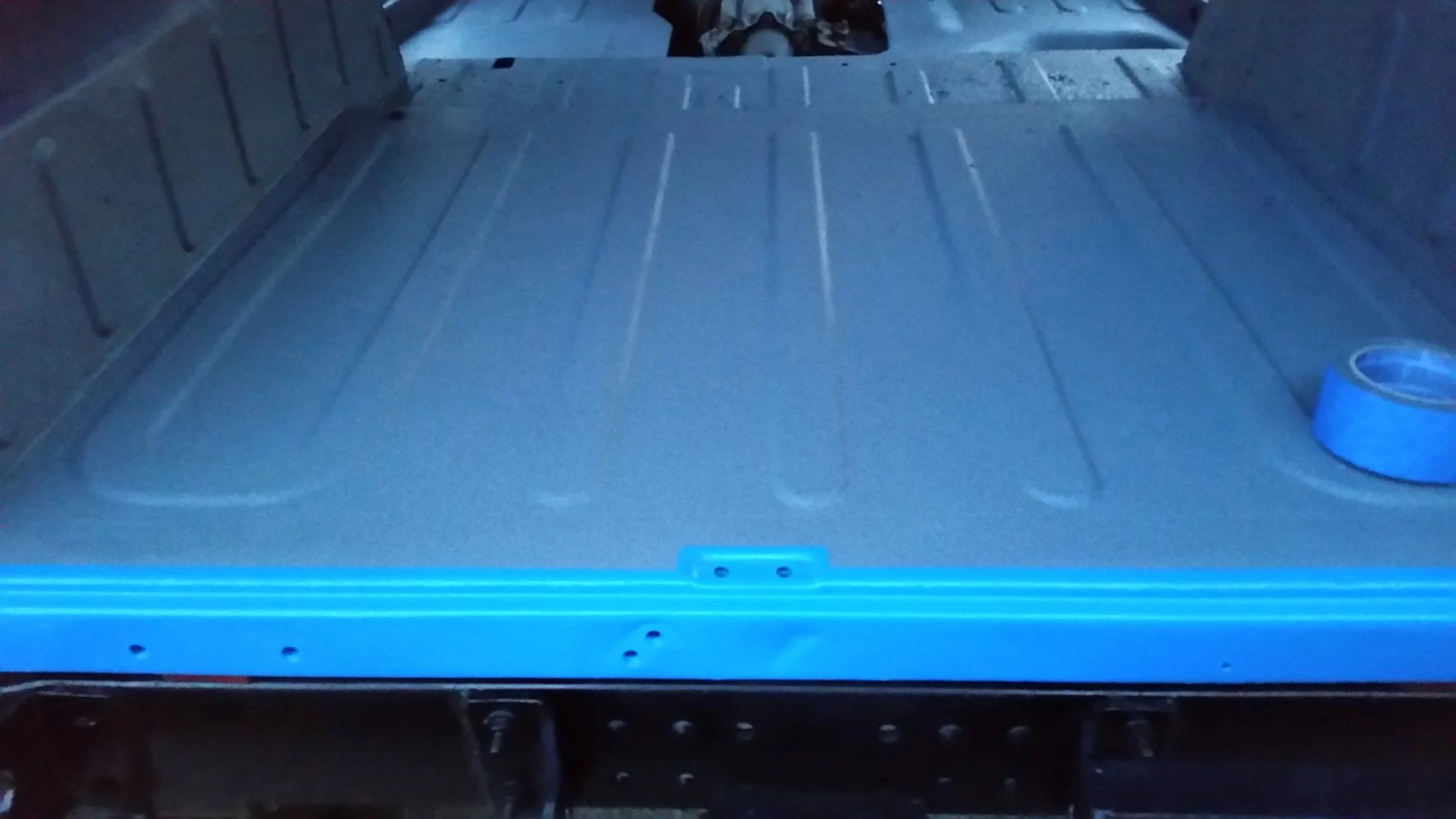

Paint shop finished prep, ready to shoot

Running boards and side skirts went to local powder coat shop.. steps in satin black, skirts in white.

2 weeks later, back home.

These pop up cannopies represented my shop for over 2 years

Needed low-range and locker engaged for Tacoma to pull it up the hill out of the backyard

Paint shop finished prep, ready to shoot

Running boards and side skirts went to local powder coat shop.. steps in satin black, skirts in white.

2 weeks later, back home.