Documenting the 7 year journey..

I bought this 77 FJ40 for $2400 back in 2011. Stock 2f and drivetrain, with SOA. It was barely driveable (no brakes) and fugly.

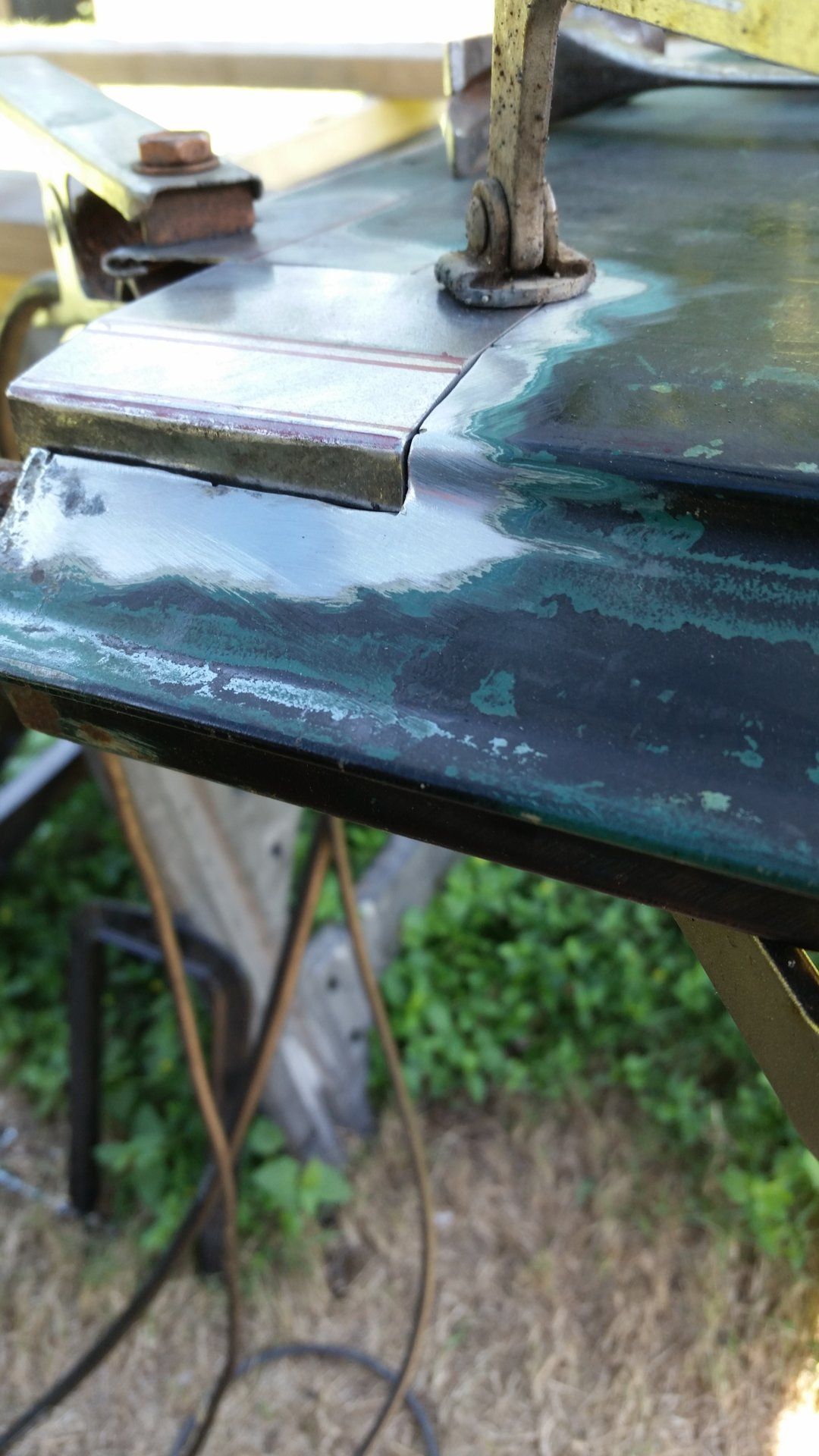

During first week I fixed the brakes and got rid of the toxic green.. 8 cans of Flat Desert Tan, a little flat black and some flat white - all rattle can.

Added some new tires, cleaned up the mess of wiring and got it inspected and legal.

I enjoyed it just like this for around 4 years. Fixing things here and there.. then about 3 years ago decided it was time for a makeover, so I tore it all apart.

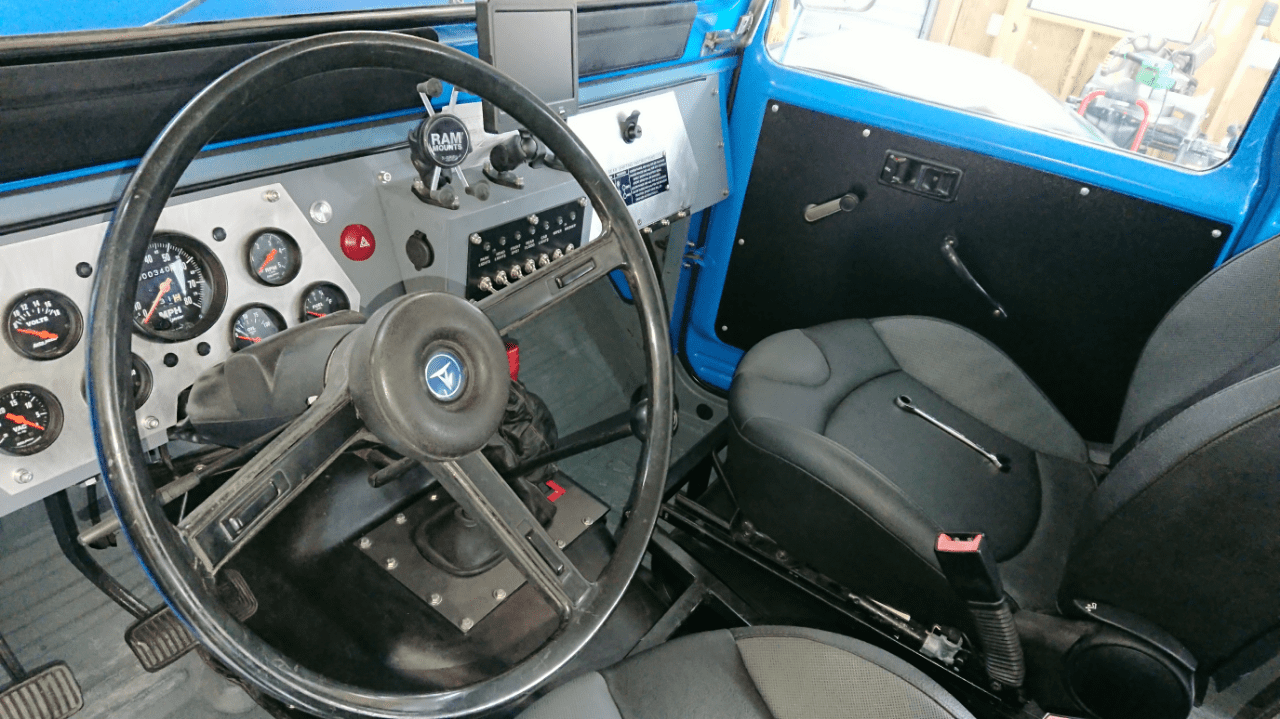

As of this month (dec 2018), it is back together again, safety inspected, legal and sporting a new look. Still on same stock 2F and drivetrain, running like a champ.

More posts to follow on what all happened in between 2011 and Dec 2018.

I bought this 77 FJ40 for $2400 back in 2011. Stock 2f and drivetrain, with SOA. It was barely driveable (no brakes) and fugly.

During first week I fixed the brakes and got rid of the toxic green.. 8 cans of Flat Desert Tan, a little flat black and some flat white - all rattle can.

Added some new tires, cleaned up the mess of wiring and got it inspected and legal.

I enjoyed it just like this for around 4 years. Fixing things here and there.. then about 3 years ago decided it was time for a makeover, so I tore it all apart.

As of this month (dec 2018), it is back together again, safety inspected, legal and sporting a new look. Still on same stock 2F and drivetrain, running like a champ.

More posts to follow on what all happened in between 2011 and Dec 2018.