Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Keeping it low with Rockwells (a.k.a. under the knife again)

- Thread starter Eskimo

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Eskimo

SILVER Star

- Thread starter

- #123

Not much picture-worthy really.. did the radiator fan mounting and catch can mount, hood pins, and am 75% done with the fuel cell mount.

Also got the rear third member assembled into the axle and painted, and installed the link mount 'helmet' (Thanks Pat!).. it'll clear the pinion brake, but juuust barely..

Lots of time was spent finalizing the rear link mounts positioning, and how to clear the pinion brake.

Oh, and I found out I had a hole in one of my wheels! Looks like when the Stazworks centers were being welded in, he had a bad weld with porosity, and it burned a small hole through the shell of the wheel... Found this out when I went to see how the wheels were holding air, and I had 3 @ 25psi, and one at 0. I figured it was the valve stem and focused my attention on that, fortunately, the bad weld was near there and a little speck caught my eye. Little bit of weld, and she's holding 25psi as well.

Looks like when the Stazworks centers were being welded in, he had a bad weld with porosity, and it burned a small hole through the shell of the wheel... Found this out when I went to see how the wheels were holding air, and I had 3 @ 25psi, and one at 0. I figured it was the valve stem and focused my attention on that, fortunately, the bad weld was near there and a little speck caught my eye. Little bit of weld, and she's holding 25psi as well.

Also got the rear third member assembled into the axle and painted, and installed the link mount 'helmet' (Thanks Pat!).. it'll clear the pinion brake, but juuust barely..

Lots of time was spent finalizing the rear link mounts positioning, and how to clear the pinion brake.

Oh, and I found out I had a hole in one of my wheels!

I love my weekly subscription/ update to this thread.

Very very clean

Very very clean

Rich are we racing to see who can get done first? ;p

End of this month huh? I will see what i can work out.

looking sweet, i cant wait to see its stance once its all done!

Eskimo

SILVER Star

- Thread starter

- #129

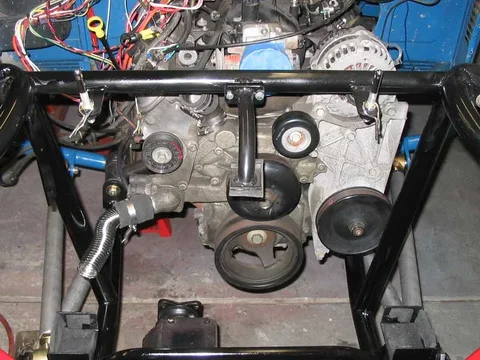

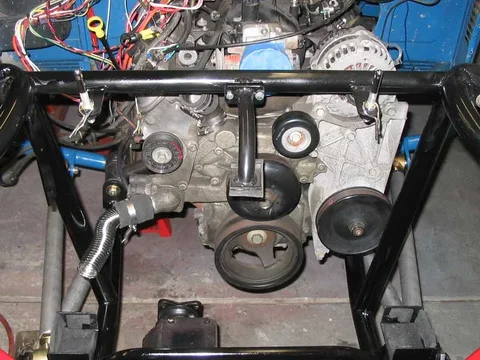

Added some needed bracing between the upper and lower tubes, since the engine will be pulling down and the coilovers pushing up. There are plans for one more going fr the shock hoop back to the stock frame rail, but that will have to wait until after the exhaust is done.

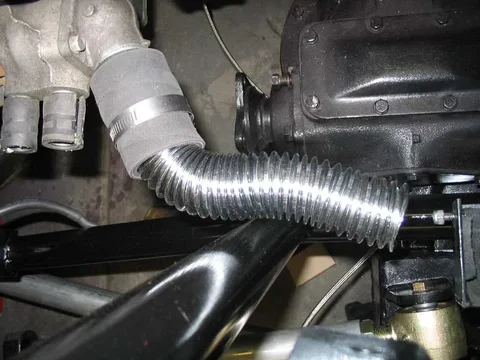

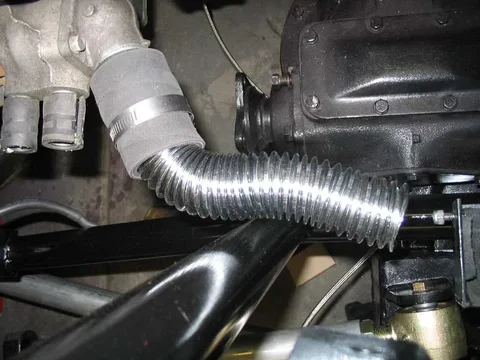

Thank goodness for this über bling and freakin pricy flex radiator hose.. it saved my bacon by letting me put the downtube where I wanted it.

Thank goodness for this über bling and freakin pricy flex radiator hose.. it saved my bacon by letting me put the downtube where I wanted it.

Eskimo

SILVER Star

- Thread starter

- #130

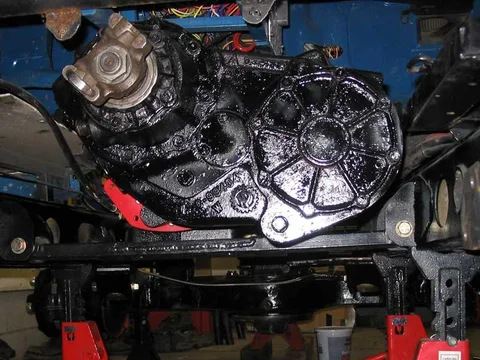

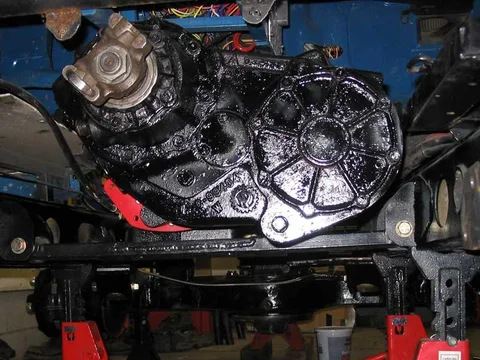

The 205 clocking plate from DD Machine finally came in, and it was worth every penny and was a HUGE help. in the OEM config, the front yoke was right on the crossmember, and the case hung below the frame rails. Now it's above the frame, and have plenty of swing for the front output...

Before:

And now:

Before:

And now:

Eskimo

SILVER Star

- Thread starter

- #131

And, the 4-link on the front is DONE!! That really feels like progress! I was able to get a little more triangulation on the front after fitting the tire and seeing where it goes when turned..

The outers took seemingly FOREVER to assemble, though the second went alot faster than the first. They look badass though! 3 lbs of grease between the 2... Just the hub and disc weighs more than an entire Toyota knuckle/spindle/hub/rotor/lockout assembly... nutty.

Just the hub and disc weighs more than an entire Toyota knuckle/spindle/hub/rotor/lockout assembly... nutty.

This is about 1" lower than ride height. I had to lower the chassis so I could use the floor jack to help with the 205...

The outers took seemingly FOREVER to assemble, though the second went alot faster than the first. They look badass though! 3 lbs of grease between the 2...

This is about 1" lower than ride height. I had to lower the chassis so I could use the floor jack to help with the 205...

Last edited:

- Joined

- Sep 26, 2005

- Threads

- 38

- Messages

- 1,824

- Location

- Port Orchard, WA

- Website

- www.projektenterprises.com

I'm off to grab some socks. Nice work man

- Joined

- Sep 28, 2002

- Threads

- 558

- Messages

- 8,122

- Location

- Kamloops, BC Canada

- Website

- www.shopraddcruisers.ca

I can almost read your excitment.................

Nice work.

Nice work.

Sweet! Looks great!

I'd like to see more pics of the link brackets at the frame and at the housing.

Thanks for the thread!

Andy

I'd like to see more pics of the link brackets at the frame and at the housing.

Thanks for the thread!

Andy

Eskimo

SILVER Star

- Thread starter

- #135

I'd like to see more pics of the link brackets at the frame and at the housing.

There's a couple of photos of the housing brackets in previous photos, but I'll take some of the frame-end ones today, along with today's progress.

(I took this week off from work as a mad dash to get this thing done)

So far today, I managed to ruin $140 in Walbro pump and fittings by apparently overtightening the fittings. I was so pissed off I can't describe it. Still angry.

Tapage

Club 4X4 Panamá

Toughest !

its coming along

lookin Sweet! it looks like you are doing a good job keeping that sucker low!

Newbie Question on the Rockwell Brakes, Why did you opt for the Brakes at each corner rather than the pinion style brakes that Proffits runs, i think that they run a stock toyota rotor and Caliper, just one per axle.. I was talking with them in moab and he said that sucker would put him thru the windshield if he layed on the brakes!

Newbie Question on the Rockwell Brakes, Why did you opt for the Brakes at each corner rather than the pinion style brakes that Proffits runs, i think that they run a stock toyota rotor and Caliper, just one per axle.. I was talking with them in moab and he said that sucker would put him thru the windshield if he layed on the brakes!

Last edited:

lookin Sweet! it looks like you are doing a good job keeping that sucker low!

Newbie Question on the Rockwell Brakes, Why did you opt for the Brakes at each corner rather than the pinion style brakes that Proffits runs, i think that they run a stock toyota rotor and Caliper, just one per axle.. I was talking with them in moab and he said that sucker would put him thru the windshield if he layed on the brakes!

He was just trying to make them cost as much as Dana axles is all

looks good rich. can't wait to see it in peson!

Similar threads

- Replies

- 0

- Views

- 564

- Replies

- 212

- Views

- 20K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)