Eskimo

SILVER Star

- Thread starter

- #81

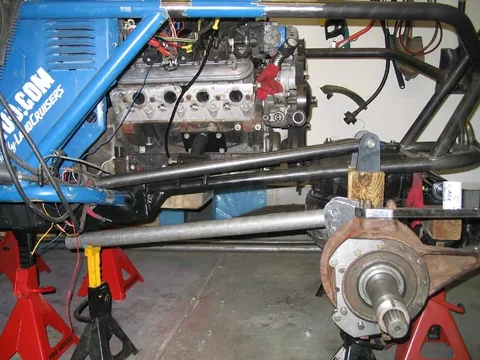

The finished product, mocked up on the machinist's axle.. The holes in the end of the arm are bored at 10° to compensate for the kingpin inclination, and the sleeve then goes straight through them, and will be welded in place.

There's another sleeve for the outer-most hole, which is also bored at 10°.

I don't think there is a stronger setup for a hi-steer system...

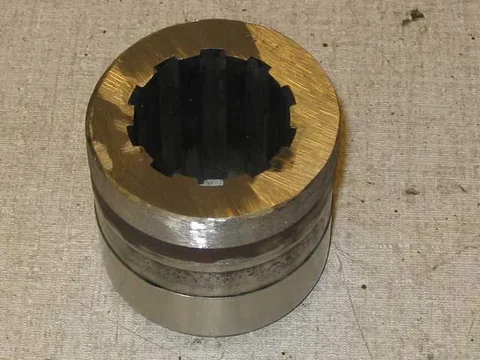

And, just a shot inside the CNC machine while it did its thing..

There's another sleeve for the outer-most hole, which is also bored at 10°.

I don't think there is a stronger setup for a hi-steer system...

And, just a shot inside the CNC machine while it did its thing..