Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Here we go (FJ-40 getting a 3B/Turbo/H55f)...

- Thread starter DanS HJ-45

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?DanS HJ-45

SILVER Star

- Thread starter

- #142

DanS HJ-45

SILVER Star

- Thread starter

- #143

In preparation for welding the quarters back on, I wanted to reinforce the mounting for the soft top. Simply drilling holes is too easy, but would be a pain to have to have two people--one to hold the nut, one to hold the bolt. So, captive nuts are an excellent solution.

Here's the plates I made for the soft top brackets (those are the red brackets).

These will be spot welded to the bottom of the inner fender, to better support the soft top.

Here it is mocked up...

It's not quite square though. I'm guessing it's because the B pillar bows are tight against the tub, so they can't quite sit square in the post hole. I'm guessing that with a little trimming, and maybe a little bit of persuasion, that I should be able to pull it square eventually. Good idea, or should I be looking for something else before I weld this stuff down?

Here's the plates I made for the soft top brackets (those are the red brackets).

These will be spot welded to the bottom of the inner fender, to better support the soft top.

Here it is mocked up...

It's not quite square though. I'm guessing it's because the B pillar bows are tight against the tub, so they can't quite sit square in the post hole. I'm guessing that with a little trimming, and maybe a little bit of persuasion, that I should be able to pull it square eventually. Good idea, or should I be looking for something else before I weld this stuff down?

DanS HJ-45

SILVER Star

- Thread starter

- #144

So, I cleaned up the motor mounts (because I'll be attaching them to the frame pretty soon). Problem is, when I bolt them to the rubber isolators on the motor they don't sit "square" in the vertical plane. The inside frame rails look square to me, but bolted securely to the motor the mounts are about 15 degrees off of vertical.

The frame side mounts came from a BJ-40, so I'm sure they are correct for the frame/engine. But the motor came from a BJ-73, and I'm wondering if the motor mounts that attach to the engine block are at a different angle than for the 40 series. Apparently I didn't snap any pics of that bit, but I will when I get home. If the 40 series and 70 series use a different motor mount on the engine itself, I can either look to replace the mounts on this engine with 40 series mounts, or I can fabricate some custom frame side motor mounts to mate with the motor mounts/isolators on the engine.

Or am I making too big of a deal out of this? If I simply attach the mounts to the frame and set the engine down will it end up square?

And lastly, just because I haven't looked at it nearly put back together recently...

It's getting REALLY close to welding the quarters back on. The left side is just waiting for me to spot weld the soft top bracket on, and then the quarter is ready. The right side has maybe 3-4 hours of rust repair left before I weld the quarter panel back on (if that--that's what it took me to do the left side--same repair).

Dan

The frame side mounts came from a BJ-40, so I'm sure they are correct for the frame/engine. But the motor came from a BJ-73, and I'm wondering if the motor mounts that attach to the engine block are at a different angle than for the 40 series. Apparently I didn't snap any pics of that bit, but I will when I get home. If the 40 series and 70 series use a different motor mount on the engine itself, I can either look to replace the mounts on this engine with 40 series mounts, or I can fabricate some custom frame side motor mounts to mate with the motor mounts/isolators on the engine.

Or am I making too big of a deal out of this? If I simply attach the mounts to the frame and set the engine down will it end up square?

And lastly, just because I haven't looked at it nearly put back together recently...

It's getting REALLY close to welding the quarters back on. The left side is just waiting for me to spot weld the soft top bracket on, and then the quarter is ready. The right side has maybe 3-4 hours of rust repair left before I weld the quarter panel back on (if that--that's what it took me to do the left side--same repair).

Dan

DanS HJ-45

SILVER Star

- Thread starter

- #145

Time for a break on the rust repair. Also, it's time to get kicking on this stuff, since the tub is so close to being done....

The 2F is now out of the frame.

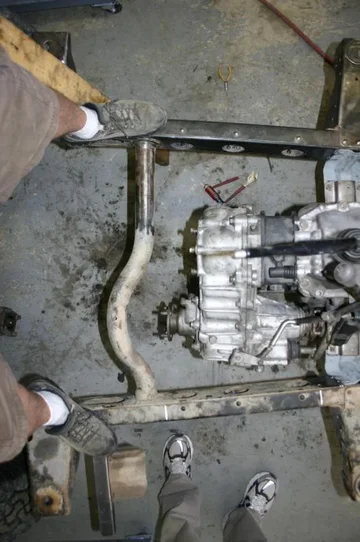

A friend (Alia176) and I hoisted the 3B/H55f into it's rough position last week, and I decided that I liked the idea of shifting the whole assembly forward a couple inches. So, I tacked the mounts for the transmission crossmember into place...

I also enlarged the holes that the crossmember actually bolts to here, because the frame is not as wide as the "correct" position.

The 2F is now out of the frame.

A friend (Alia176) and I hoisted the 3B/H55f into it's rough position last week, and I decided that I liked the idea of shifting the whole assembly forward a couple inches. So, I tacked the mounts for the transmission crossmember into place...

I also enlarged the holes that the crossmember actually bolts to here, because the frame is not as wide as the "correct" position.

DanS HJ-45

SILVER Star

- Thread starter

- #146

So, with the crossmember in place, we set the motor into place to start making some motor mounts.

Problem: the factory steering gearbox interfered with the starter on this 3B (which came from a BJ-73), and pushed the motor WAY over to the passenger side.

With the motor like this, the output shafts of the T-case didn't remotely point towards either differential. So, we removed the steering gearbox.

I don't know if this was because this 3B was from a 70 series, or because I shifted the whole thing a couple inches forward (but the starter was pretty much centered on the steering gearbox, so it would have had to move back a good 3" to clear).

Problem: the factory steering gearbox interfered with the starter on this 3B (which came from a BJ-73), and pushed the motor WAY over to the passenger side.

With the motor like this, the output shafts of the T-case didn't remotely point towards either differential. So, we removed the steering gearbox.

I don't know if this was because this 3B was from a 70 series, or because I shifted the whole thing a couple inches forward (but the starter was pretty much centered on the steering gearbox, so it would have had to move back a good 3" to clear).

DanS HJ-45

SILVER Star

- Thread starter

- #147

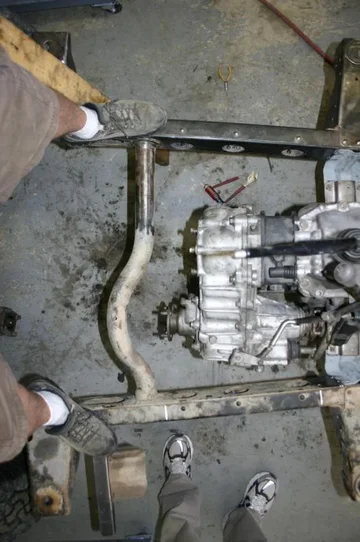

So, with the steering gearbox removed, here's how it lines up...

Pay no attention to Dad holding the Donaldson filter there, I'll discuss that in a bit. With the radiator support and fan shroud installed, it centers up nicely.

And here it is from the side... Looks to be about right as far as the angle goes.... At least to me it does.

And here's how the transmission/transfer case are lining up there...

Looks to me like it's lining up with the driveshafts and differentials just perfectly.

Pay no attention to Dad holding the Donaldson filter there, I'll discuss that in a bit. With the radiator support and fan shroud installed, it centers up nicely.

And here it is from the side... Looks to be about right as far as the angle goes.... At least to me it does.

And here's how the transmission/transfer case are lining up there...

Looks to me like it's lining up with the driveshafts and differentials just perfectly.

crushers

post ho

looking good buddy... keep up the excellent work.

DanS HJ-45

SILVER Star

- Thread starter

- #149

But there's a small problem, which you can see in the side view above. The motor mounts at pretty high. The engine isn't completely level, so the right side motor mount will come down a little, but I'm not too sure how far. Maybe an inch, maybe two?

So here's some closer pictures. Don't mind the battery tray--it won't fit either way, so I'll be fabricating a battery tray into the motor mount I build--but I was wanting a bigger tray anyway, so it's not too bad.

Here's how the left side looks. Much better IMHO.

Now, I could lower the whole thing (transmission and all), but I'm not sure how far below the frame I want to go with the T-case and crossmember.

Are these motor mounts going to be a problem? Since they are above the frame, they won't be pressing directly against the frame. I've never seen a motor mount like that before, and it sounds a bit wierd to me. I'm guessing that the B motors installed in 40 series trucks had different motor mounts bolted to them, which were lower than these 70 series brackets. Am I correct in thinking that?

I'm hoping to tack up some motor mounts tomorrow, so I can show more of what I'm thinking of then.

Dan

So here's some closer pictures. Don't mind the battery tray--it won't fit either way, so I'll be fabricating a battery tray into the motor mount I build--but I was wanting a bigger tray anyway, so it's not too bad.

Here's how the left side looks. Much better IMHO.

Now, I could lower the whole thing (transmission and all), but I'm not sure how far below the frame I want to go with the T-case and crossmember.

Are these motor mounts going to be a problem? Since they are above the frame, they won't be pressing directly against the frame. I've never seen a motor mount like that before, and it sounds a bit wierd to me. I'm guessing that the B motors installed in 40 series trucks had different motor mounts bolted to them, which were lower than these 70 series brackets. Am I correct in thinking that?

I'm hoping to tack up some motor mounts tomorrow, so I can show more of what I'm thinking of then.

Dan

DanS HJ-45

SILVER Star

- Thread starter

- #150

looking good buddy... keep up the excellent work.

Thanks Wayne. I take a long time, because the engineer/perfectionist in me just hates doing anything that's not "perfect," but I have yet to do a project that I haven't been tickled pink with.

But getting back to that Donaldson...

Here it is mocked into my HJ-45. The H has an alternator sticking out on the left side, which makes it sit a little too high and outside.

And on Dad's 40, without said alternator, here's a better shot of Dad holding it in place. The fender/apron here is bolted on all the way down, so there will actually be a little more clearance from the hood when all is said and done most likely.

I like it. This size filter is pretty big, but it avoids having to do anything other than 3" tube from the filter to the turbo inlet. Simple is good!

More tomorrow when I tack up the motor mounts to show what I'm thinking/debating. Plus, I believe that if it all fits nicely like this, that it will get 60 series power steering. It's a factory PS truck, and Dad will never go bigger than 33x9.50 tires, and it drove just fine before all of this, so we weren't originally going to swap to 60 series, but it looks to be an easy solution, with obvious benefits. The only downside of that is that the truck had original power steering, but with the diesel swap, it's already not original, so probably not an issue.

It's nice to have a 60 series box lying around (for my 45 someday) to mock up/mount.

Dan

crushers

post ho

umm those location for the motor mounts look pretty good...

why not see of some has the original B mounts sitting around on an old wreck and use them or copy?

why not see of some has the original B mounts sitting around on an old wreck and use them or copy?

DanS HJ-45

SILVER Star

- Thread starter

- #152

umm those location for the motor mounts look pretty good...

why not see of some has the original B mounts sitting around on an old wreck and use them or copy?

I've got the frame side 40 series/B motor mounts, but it appears to me that the 40 and 70 series used very different motor mounts attached to the 3B. I don't have any pictures of those. EDIT--it looks to me like the 70 series used the brackets on the motor to position the motor to the left side, and the 40 series used the frame motor mounts to position the motor to the left side. Which would explain why using both together doesn't work so well.

I'll probably call around right away tomorrow to see if there are any easily available.

The right side is literally only an inch below the TOP of the shock absorber right now. It will come down a bit as the engine sits level, but it will still be a good 2-3 inches above the top of the frame.

I'll try to get better pictures tomorrow.

Dan

Last edited:

crushers

post ho

ah, the engine side mount peices. yes the 70 is quite a bit different from the 40 series mounts...

DanS HJ-45

SILVER Star

- Thread starter

- #154

ah, the engine side mount peices. yes the 70 is quite a bit different from the 40 series mounts...

Exactly. Looks like 12311-56030 for the right, 12315-56011 on the left for the BJ-42. Looks considerably different in the EPC for the BJ-52, than the BJ-60 or 70/73. I think that's where the problem lies.

Time to make some calls... Engine mounting brackets from a BJ-42.... That said: the BJ-40 uses 12311-56010/12315-87304. Anyone have a good picture of the difference between the BJ-42 and BJ-40 engine mounting brackets?

Dan

Awl_TEQ

Supporting Vendor

I can take a snap of my BJ42 3B - its on a stand with the block brackets still on (don't mind the rust). I also have the frame brackets. I can post a pic @ around 4:30 PM Pacific when I get home.

DanS HJ-45

SILVER Star

- Thread starter

- #156

I can take a snap of my BJ42 3B - its on a stand with the block brackets still on (don't mind the rust). I also have the frame brackets. I can post a pic @ around 4:30 PM Pacific when I get home.

Fantastic! That would be much appreciated.

I'm going to go tack up some mounts to make what I've got work, just to see if I like it (or how much I hate it).

Dan

Awl_TEQ

Supporting Vendor

Awl_TEQ

Supporting Vendor

DanS HJ-45

SILVER Star

- Thread starter

- #159

You weren't kidding about the rust!

I like that RH engine mounting bracket a lot more than the one I've got. I'll have to get one...

But, Alia176 was here again today and we decided that the factory 40 series frame mount on the left side looked close enough, so I tacked it onto the frame. Frankly, I like it.

And here's the overview of how it all fits together with that motor mount tacked to the frame.

Problem is: here's my right motor mount. Don't laugh.

That's why I need to source a 40 series RH bracket. Being over 3" above the frame on the right side just isn't a good design. I can't imagine that the torque would allow such a design to last very long. Not only is it pretty high, but it's directly above the frame.

I like that RH engine mounting bracket a lot more than the one I've got. I'll have to get one...

But, Alia176 was here again today and we decided that the factory 40 series frame mount on the left side looked close enough, so I tacked it onto the frame. Frankly, I like it.

And here's the overview of how it all fits together with that motor mount tacked to the frame.

Problem is: here's my right motor mount. Don't laugh.

That's why I need to source a 40 series RH bracket. Being over 3" above the frame on the right side just isn't a good design. I can't imagine that the torque would allow such a design to last very long. Not only is it pretty high, but it's directly above the frame.

Last edited:

DanS HJ-45

SILVER Star

- Thread starter

- #160

Just a few more detailed pictures of why the 70 series engine mount brackets are a problem on the right side...

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)