crushers

post ho

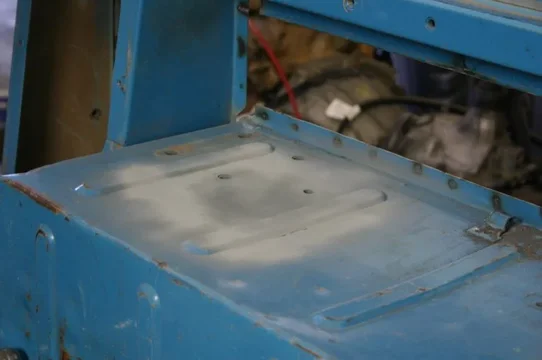

congrates on a nice job buddy.

looking good.

i agree, a second set of hands is very nice to have.

looking good.

i agree, a second set of hands is very nice to have.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

a retainer bar for a YJ works well up front and cheap.

i have installed those tops before and they are NICE.

the waste gate actuator line will work fine with a small "T" installed.

looking nice buddy.

Looks great, Dan! Just down from the top of Kilimanjaro, viewing ih8mud in Arusha, Tanzania. Cruisers everywhere here - 40s, 75s, & everything in between, almost all diesels. Saw an old 40 being restored in Marangu - just like home!

Dad