DanS HJ-45

SILVER Star

- Thread starter

- #101

This is a slight crosspost from the 40 section, but I got to welding the rocker panel in today...

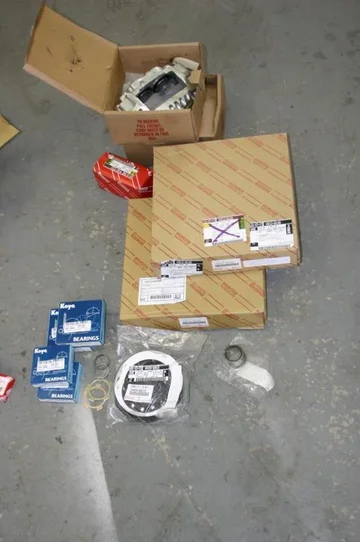

And here's some pics of the PS bracketry that I powder coated yesterday. It looks so good!

The idler pulley at goes into this bracket:

The FJ-80 (with the 3FE, not the 1FZJ) has the same profile pulley. That is good. Unfortunately, the stock bearing ID is too large to fit with the 3B PS idler assembly, and the pulley ID/bearing OD is different from the one off the original 3B idler. So, I'm going to see if a bearing shop can come up with anything. I figure NSK has got to make a bearing that would work somehow.

More in a bit, I again forgot my camera cable, so these were just pics off of my camera phone.

Dan

And here's some pics of the PS bracketry that I powder coated yesterday. It looks so good!

The idler pulley at goes into this bracket:

The FJ-80 (with the 3FE, not the 1FZJ) has the same profile pulley. That is good. Unfortunately, the stock bearing ID is too large to fit with the 3B PS idler assembly, and the pulley ID/bearing OD is different from the one off the original 3B idler. So, I'm going to see if a bearing shop can come up with anything. I figure NSK has got to make a bearing that would work somehow.

More in a bit, I again forgot my camera cable, so these were just pics off of my camera phone.

Dan