Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front Drive Shaft (AKA CV’s) reboot, Help!

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?2001LC

SILVER Star

- Thread starter

- #23

I really need to get that tool before any more band tightening.Good update- I told ya those replacement band clamps are hard to get to crimped to factory spec with the pliers type tool- requires the OTC Tool I suggested.

Be cool if you post that/those tools in this thread also

2001LC

SILVER Star

- Thread starter

- #25

THX @abuck99 I'm going to get that for my tool box, sooner or later I'll need it.

With snow predicted for tomorrow I wanted to get this front end button up. So I managed to get the last 2.6 mm SR (snap ring) in the state today, 30 mile drive and twice the price but happy to have it.

Wheel bearing breakaway pre-load set to 12.5lb on both PS & DS.

PS hub flange to SR gap was >0.04mm with the 2.6mm SR. DS was 0.15mm gap with a 2.4mm SR.

So next I torque on the calipers to 90ft-lbf, attached the speed sensor and brake line brackets and mounted the wheel & tires.

Then put ~1.8qt of M1 75-90 LSD in the differential and button up with new drain & fill plug washer (gaskets).

I was on a roll, and felt it a good idea for test drive to lube propellers first. On a roll until I pulled out my pneumatic (Harbor Freight) grease gun. It's great once I get grease gun flowing, but getting it primed, is a 30 minutes job on a good day... PITA. But it really works well for grease the propeller shaft slip yokes and spiders. A little trick I learned; is to massage slip yoke seal with grease, then used the pneumatic power and compression of drive train to pump yoke in and out. Gently, not exerting to much pressure on differential & transfer case with the pneumatic pressure.

Worked like a charm again, as grease passed the seal(s).

Finally the test drive. It was sweet no vibration, handle was tight and steering true. This was also my first drive since pulling intake, and it ran like a dream. The Redbarons' got pep.

With snow predicted for tomorrow I wanted to get this front end button up. So I managed to get the last 2.6 mm SR (snap ring) in the state today, 30 mile drive and twice the price but happy to have it.

Wheel bearing breakaway pre-load set to 12.5lb on both PS & DS.

PS hub flange to SR gap was >0.04mm with the 2.6mm SR. DS was 0.15mm gap with a 2.4mm SR.

So next I torque on the calipers to 90ft-lbf, attached the speed sensor and brake line brackets and mounted the wheel & tires.

Then put ~1.8qt of M1 75-90 LSD in the differential and button up with new drain & fill plug washer (gaskets).

I was on a roll, and felt it a good idea for test drive to lube propellers first. On a roll until I pulled out my pneumatic (Harbor Freight) grease gun. It's great once I get grease gun flowing, but getting it primed, is a 30 minutes job on a good day... PITA. But it really works well for grease the propeller shaft slip yokes and spiders. A little trick I learned; is to massage slip yoke seal with grease, then used the pneumatic power and compression of drive train to pump yoke in and out. Gently, not exerting to much pressure on differential & transfer case with the pneumatic pressure.

Worked like a charm again, as grease passed the seal(s).

Finally the test drive. It was sweet no vibration, handle was tight and steering true. This was also my first drive since pulling intake, and it ran like a dream. The Redbarons' got pep.

Last edited:

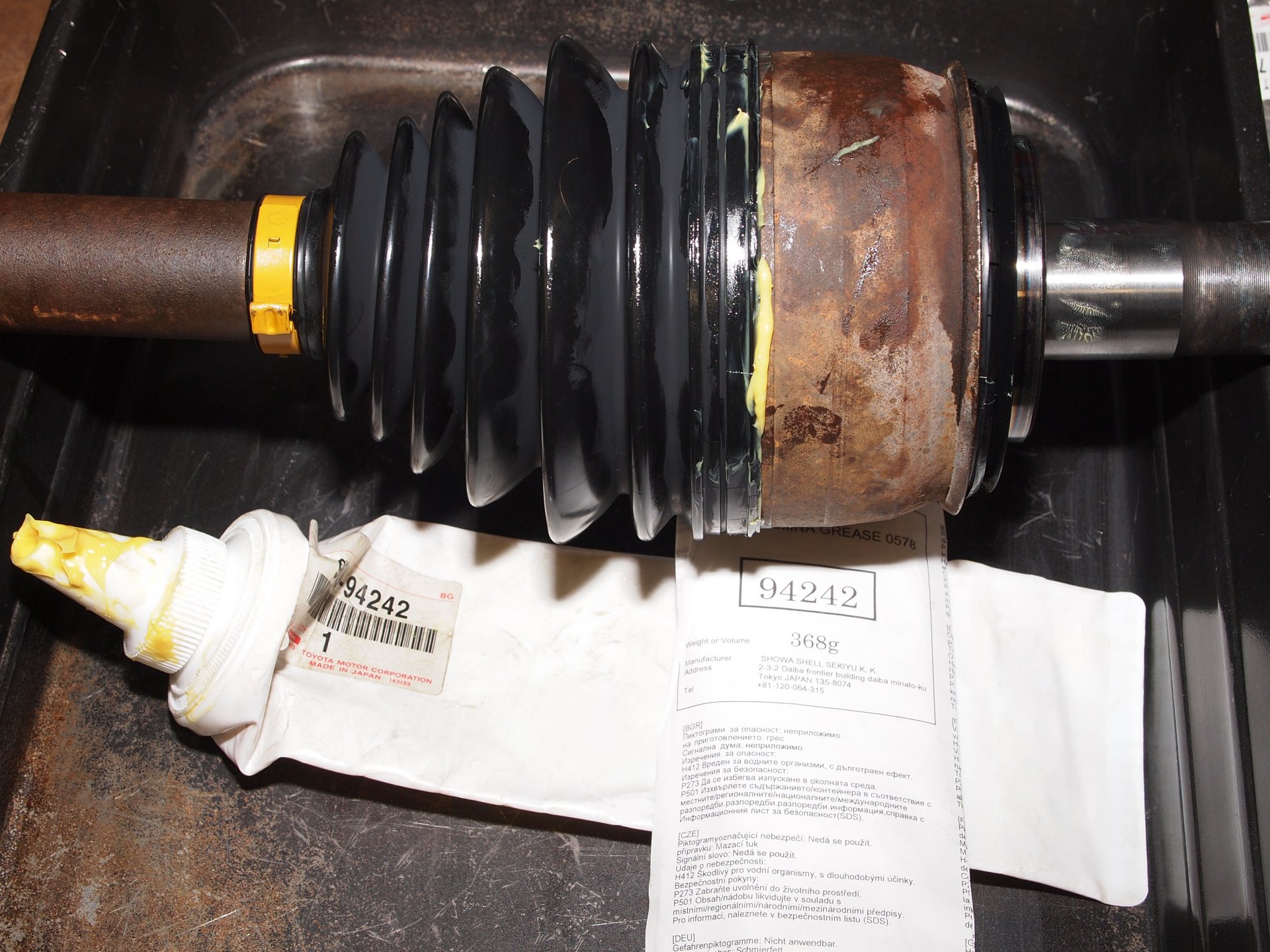

Vise made easy work of filling outboard boot with grease.

Took all my weight on crimpers to tighten outboard clamps, and they could still take more squeezing if needed. Those are for sure heavier than the factory clamps.

They changed snap ring so it no longer has eyelets. Unfortunately my various snap ring tool attachments disappeared long ago. Made getting on a little more difficult for me. One went right on the other kept slipping off my tool (5 min extra).

I know the grease for the inboard and outboard joints has different part number. Do you know if they are the same grease, just different amount?

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)